Independent foundation closed type formwork structure and process

An independent foundation and closed technology, applied in basic structure engineering, construction and other directions, can solve the problems of poor compactness, large molding size error, surface honeycomb hemp surface, etc., to improve overall performance, ensure flatness, and improve compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

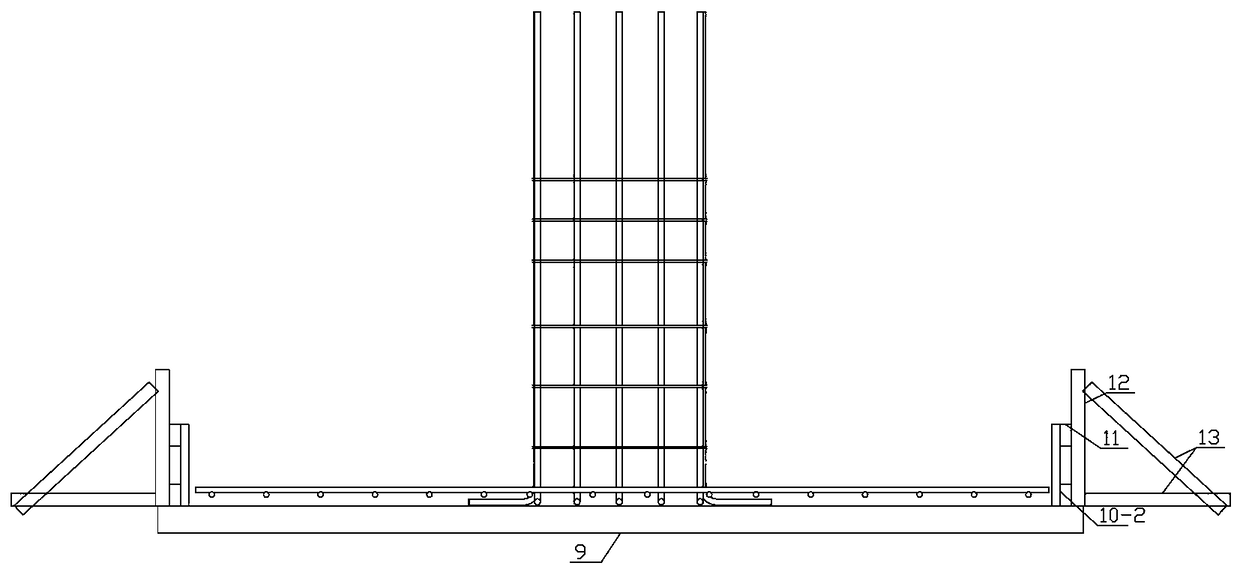

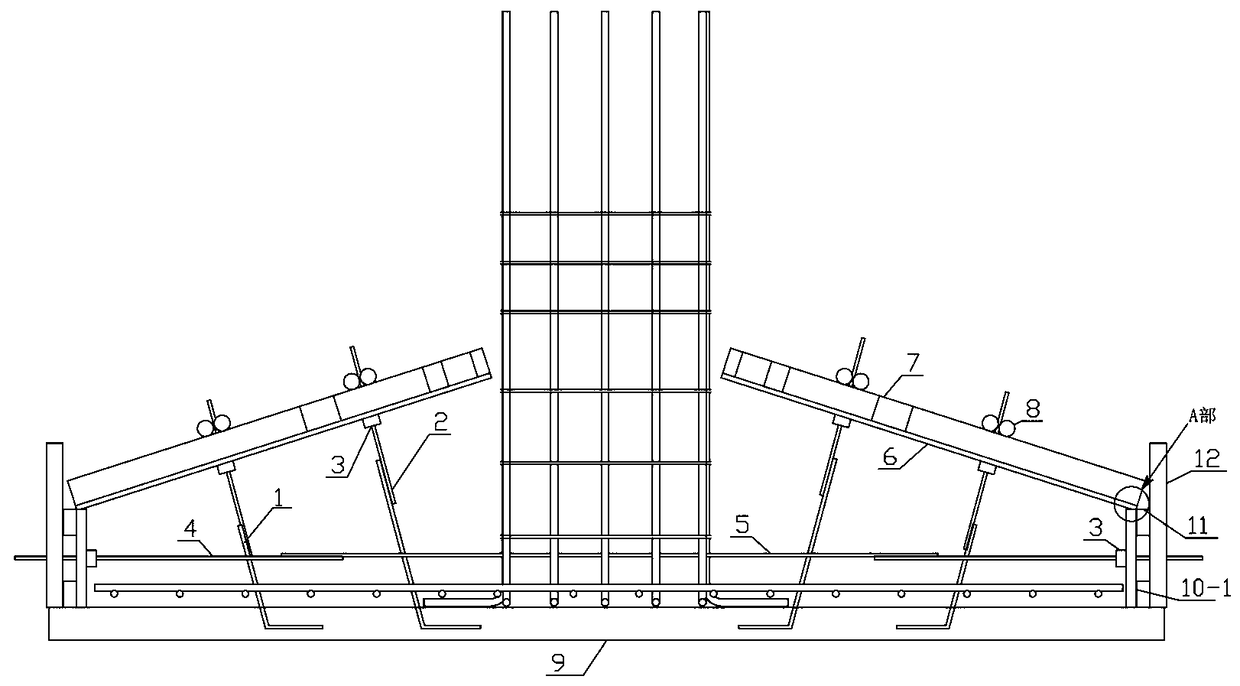

[0025] Example 1: In figure 1 middle( figure 1 There is no slope template 6, pre-embedded tie bars 1, oblique tension bolts on the slope surface 2, horizontal tension bolts 4, horizontal tie bars, rubber gaskets 3), pre-embedded tie bars 1, oblique 2 pull bolts, 3 rubber gaskets, 4 horizontal pull bolts, 5 horizontal tie bars, 6 slope formwork, 7 square timber (back corrugated slope formwork), 8 steel pipes (slope formwork keel), 9 concrete cushion , side formwork 10, square wood (side formwork back corrugated) 11, steel pipe (side formwork keel) 12.

[0026] see figure 2 , the closed formwork construction process of the independent foundation, the two ends of the horizontal tie bars 5 are welded with the horizontal pull bolts 4 passing through the side formwork 10, the inner side is covered with rubber gaskets 3, and the butterfly card and the steel pipe (side formwork keel) 12 are used. Connecting and fixing the square timber (back corrugated side formwork) 11, formwork ...

Embodiment 2

[0033] Embodiment 2: The closed formwork support structure of the independent foundation includes templates, square timber, steel pipes, steel bars, tension bolts and concrete cushion 9, etc. Such as figure 1 with figure 2 As shown, the inclined tie bars are pre-embedded in the concrete cushion 9 as the traction support ends of the left and right inclined panels. The formwork structure improves the overall performance of the independent foundation formwork system. In the independent foundation cushion layer, the tie bars 1 are pre-embedded and welded to the paired wires, and the paired wires tie the slope formwork 6 to resist the buoyancy of the concrete to the slope formwork 6, so that the independent foundation formwork system is firm and stable.

[0034]There are many groups of templates, which are four side templates and slope templates 6 respectively. Each side formwork is sealed and butted in turn, and fixed on the upper side of the concrete cushion 9.

[0035] The ...

Embodiment 3

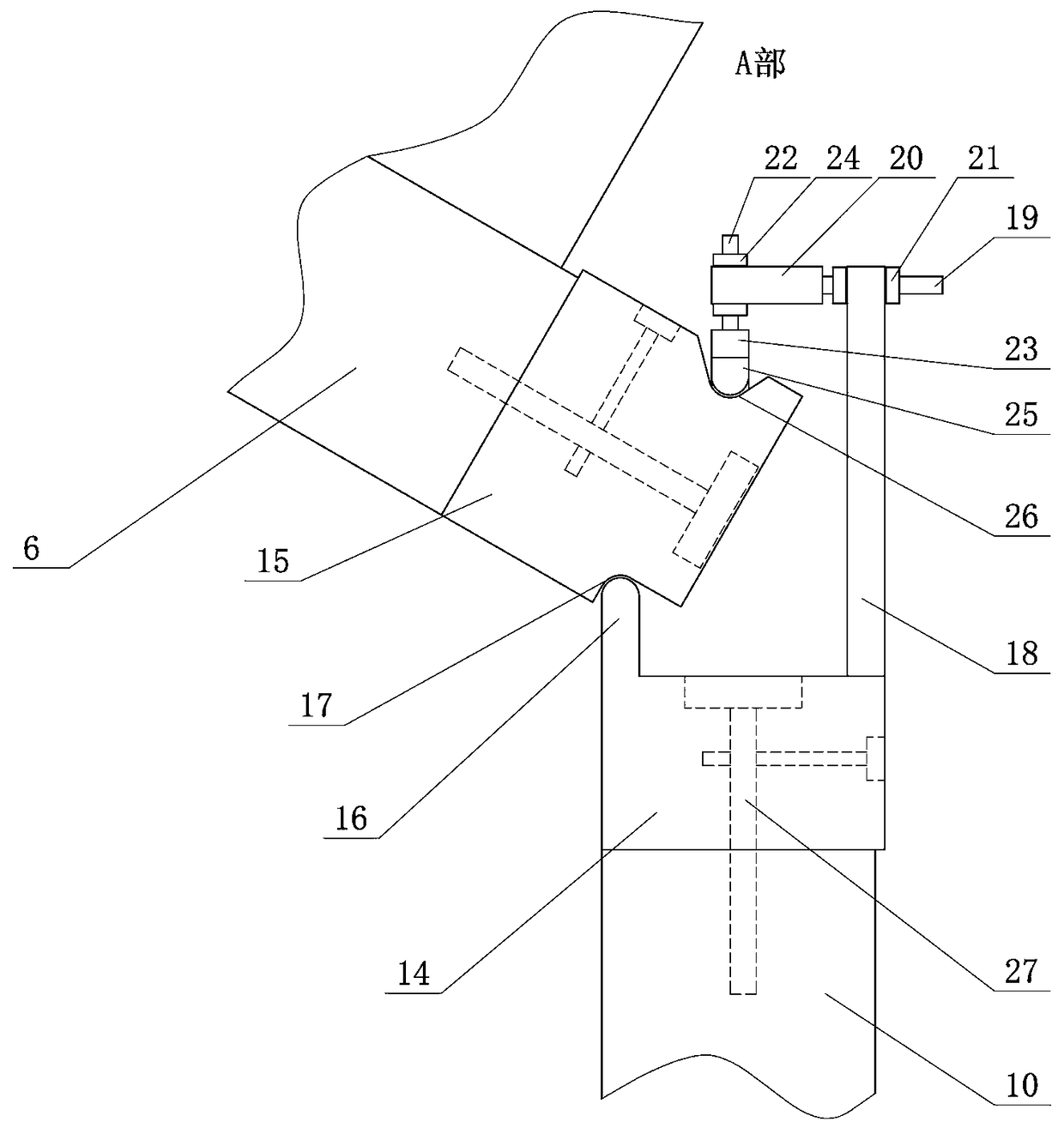

[0040] Embodiment 3: On the basis of Embodiment 2, the sealed butt joint structure adopted includes vertical end seats 14 fixed on the upper side of the left and right side formwork 10-1 and inclined end seats 15 fixed on the lower side of the left and right slope formwork 6 . see image 3 As shown, the inner side of the vertical end seat 14 is upwardly provided with a support plate 16, the upper edge of the support plate 16 is arc-shaped, the inner middle part of the inclined end seat 15 is provided with a support groove 17, and the groove bottom of the support groove 17 is concave arc-shaped, The upper edge of the support plate 16 is matched and installed in the support groove 17 . Simultaneously, column 18 is fixed on the outside of described vertical end seat 14, and column 18 upper end horizontal thread is connected with horizontal screw rod, and the inner end of horizontal screw rod is fixed with horizontal slide block, and vertical screw rod is threaded on the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com