Power transmission iron tower grounding electrode steel pile driving device and driving method

A technology for transmission towers and grounding electrodes, applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of inconvenient tool carrying, low piling construction efficiency, high labor intensity, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

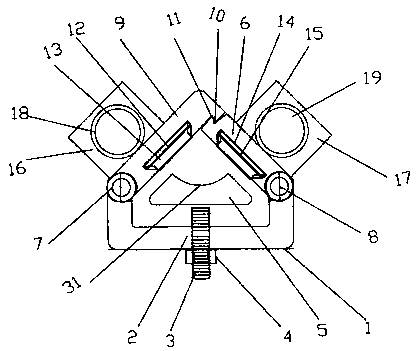

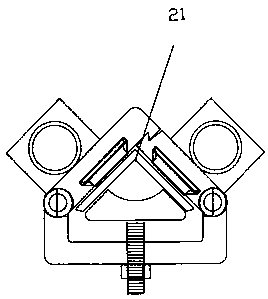

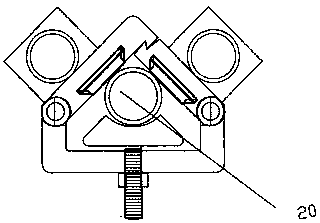

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

[0020] A power transmission tower grounding pole steel pile driving device, comprising a half-shaped hoop base 1, a threaded through hole 2 is arranged on the crossbeam of the half-shaped hoop base 1, and a threaded through hole 2 is screwed into the threaded through hole 2 The top screw bolt 3 is provided with a left pin 7 at the top of the left longitudinal beam of the half-shaped hoop base 1, a left pendulum block 9 is hinged on the left pin shaft 7, and a left pendulum block 9 is arranged on the inner side of the left pendulum block 9. The left wedge-shaped block is inserted into the groove 12, and the left pile hammer striking block 16 is fixedly welded on the outer surface of the left pendulum block 9, and the left pile hammer bucket 18 is fixedly connected to the top surface of the left pile hammer striking block 16. The top of the block 9 is provided with a left buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com