Concrete tube with lining elastic plastic sheet

A technology of elastic plastic and concrete pipes, applied in the direction of coating, etc., can solve the problems that affect the service life of the pipes, and cannot hinder the infiltration of gas or water, and achieve the effect of good sealing effect, low maintenance cost and large water delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

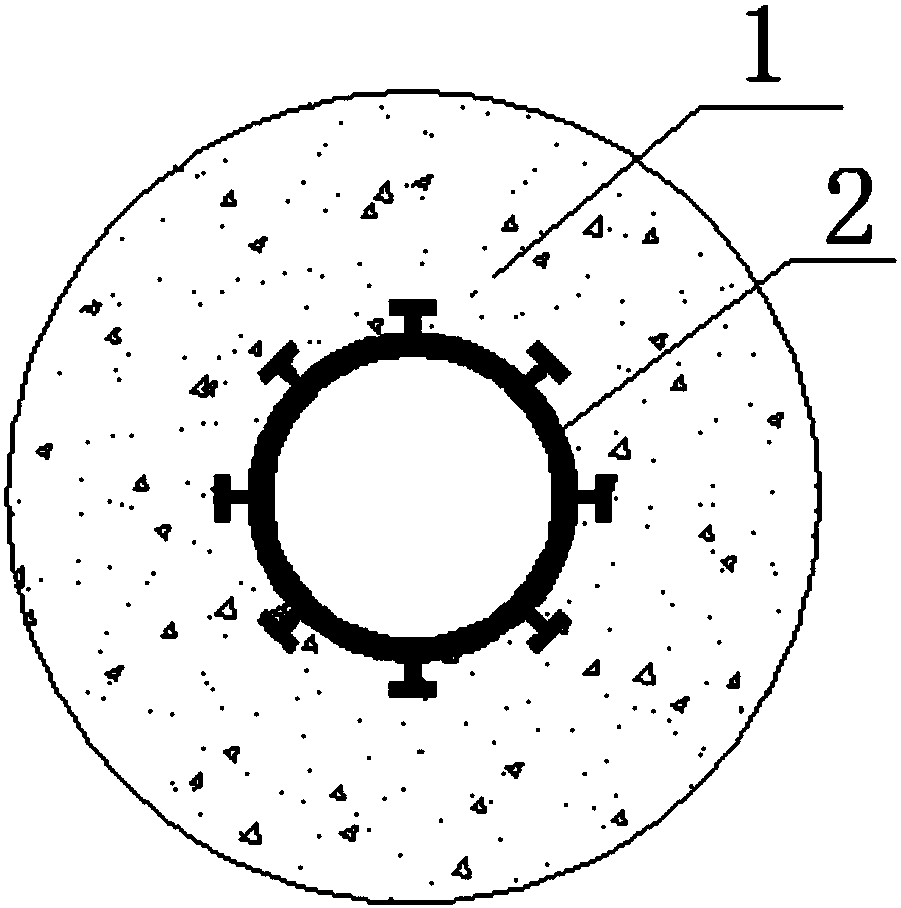

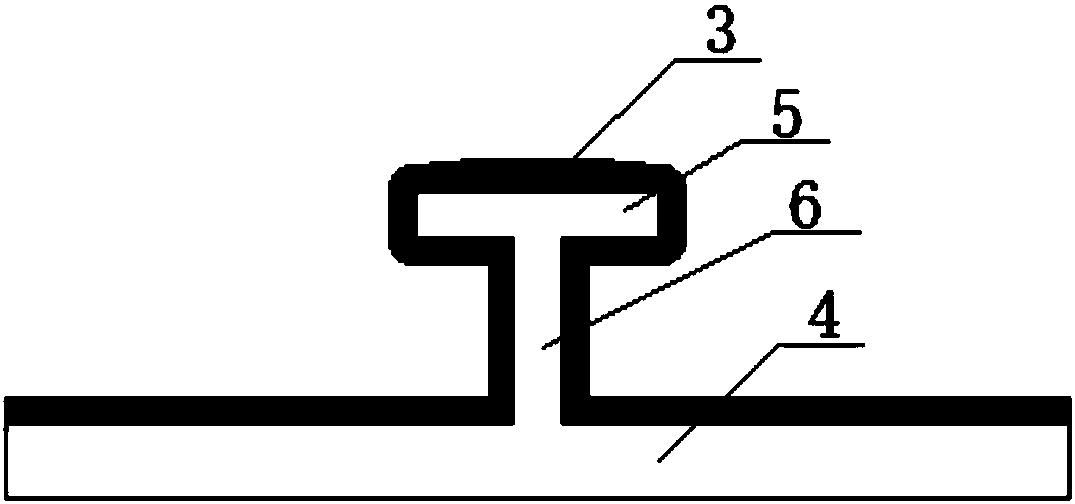

[0026] A concrete pipe lined with an elastic plastic sheet, such as figure 1 , figure 2 As shown, it includes a lining elastic plastic sheet 2 and a concrete structure layer 1 wrapped outside the lining elastic plastic sheet 2. The lining elastic plastic sheet 2 is composed of a base layer 4 and an elastic layer 3, and the base layer 4 is on the inside , the elastic layer 3 is on the outside, used to contact with the concrete structure layer 1, and an anchoring structure is arranged on the outside of the lining elastic plastic sheet 2, and the anchoring structure extends into the concrete structure layer 1, so that the lining elastic plastic sheet 2 It is firmly combined with the concrete structure layer 1 and has better sealing performance.

[0027] Wherein, along the length direction of the lining elastic plastic sheet 2, the anchoring structures are arranged at intervals with a distance of 5cm-20cm, and along the circumferential direction of the lining elastic plastic she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com