Measuring Method of Detector Angle Deviation in Cone Beam CT System Based on Feature Texture Template

A technology of angle deviation and detector, which is applied in the field of computer tomography, can solve the problems of difficult template making and complicated measurement operation steps, and achieve the effect of solving complicated template making, easy template making, and complicated measurement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

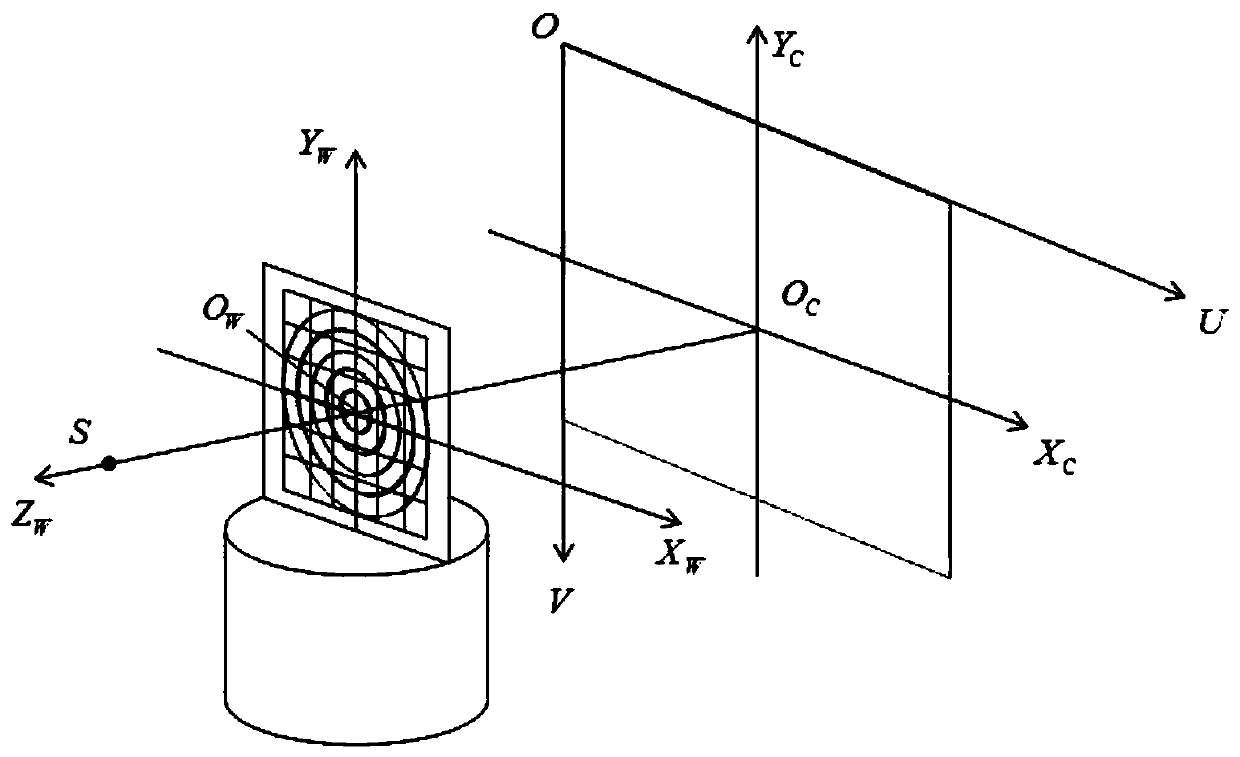

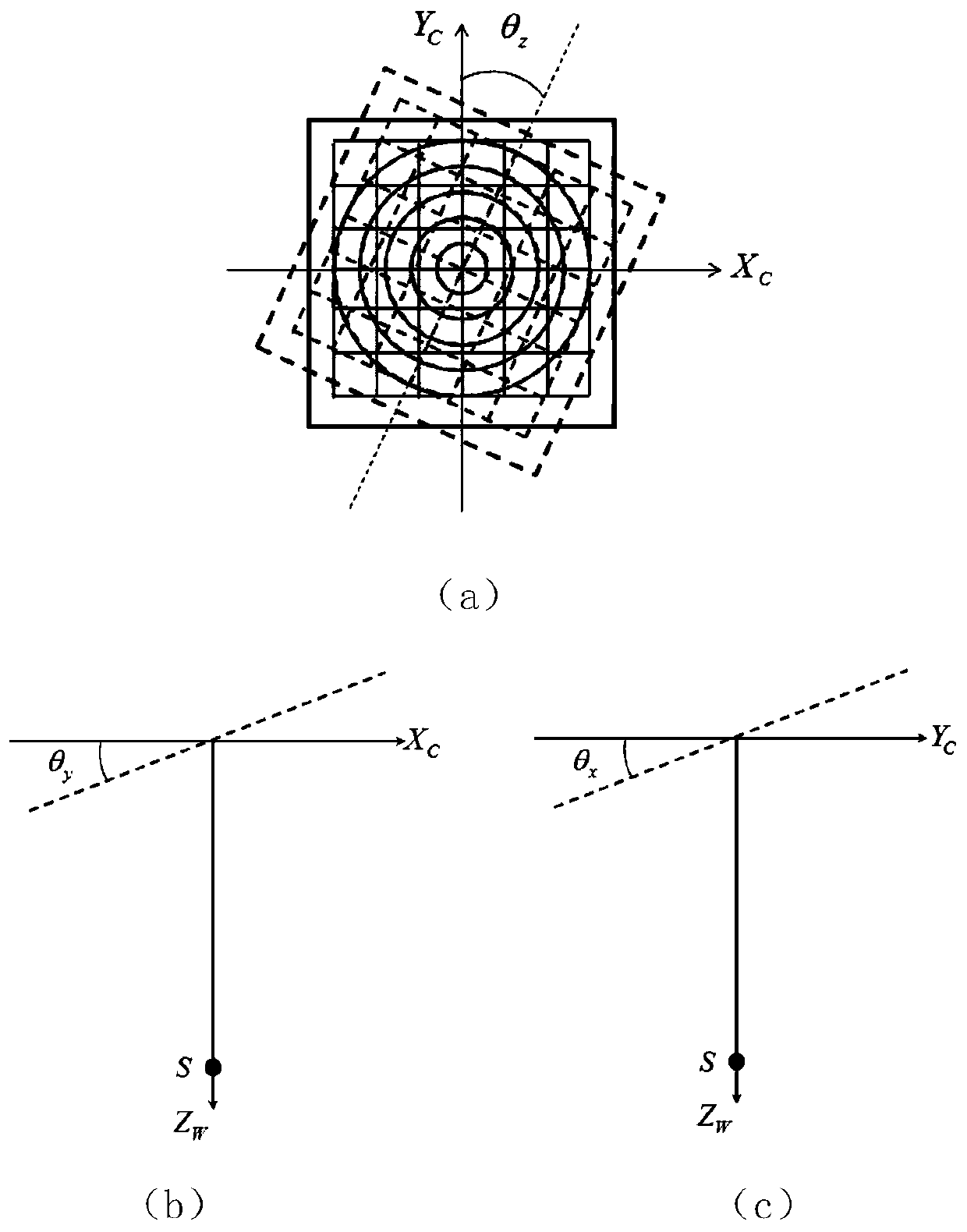

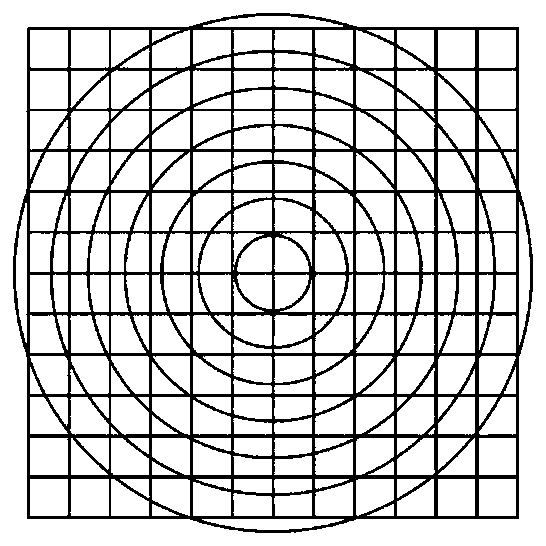

[0068]The ray source is a COMMET ray source, and the PaxScan 1313DX detector is used to collect projection images with a resolution of 1024×1024, a pixel size of 0.127mm, and a Gigabit Ethernet interface. The estimated distance from the ray source to the detector is 1000mm. The texture on the calibration template is the superposition of checkerboard texture and concentric ring texture. The size of the template is 100mm×100mm, the checkerboard is 10×10, the length and width of each small square are 8mm, and there are 5 concentric rings in total. , taking the center of the checkerboard as the center, the minimum radius is 8mm, other radii are based on the minimum radius, and the interval is 8mm. The width of each line on the template is 1mm.

[0069] Step 1. Obtain the projection image of the calibration template and determine the initial value. The initial value of the angle parameter θ x =0,θ y =0,θ z =0, the initial value of the normalized displacement parameter

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com