Fault-visible type lightning arrester and manufacturing method thereof

A manufacturing method and lightning arrester technology, applied in non-adjustable metal resistors, resistors, resistor components, etc., can solve problems such as difficulty in large-scale promotion, large manpower consumption, increased leakage of lightning arresters, etc., and reduce fault finding time, reduce operation and maintenance work, and the effect of reliable tripping mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A manufacturing method of a visual fault arrester, the specific steps are as follows:

[0028] Step 1. Process three axially distributed annular grooves on the outer surface of the outer periphery of the lower end of the lightning arrester porcelain bushing by groove drawing technology. The thickness and strength of the annular grooves are lower than those of other parts of the lightning arrester porcelain bushing; The cross-sectional shape of the annular groove is arc-shaped or polygonal.

[0029] Step 2. Put the mandrel inside the arrester porcelain sleeve and fill the adhesive between the arrester porcelain sleeve and the mandrel. The adhesive is used to seal and prevent the arrester porcelain sleeve from splashing due to the explosion of fragments. The said The adhesive is a water-soluble adhesive containing polyvinyl alcohol, liquid silicone rubber, and hydroxypropyl methylcellulose. ;

[0030] Step 3. On the high-voltage electrode connected to the mandrel on the...

Embodiment 2

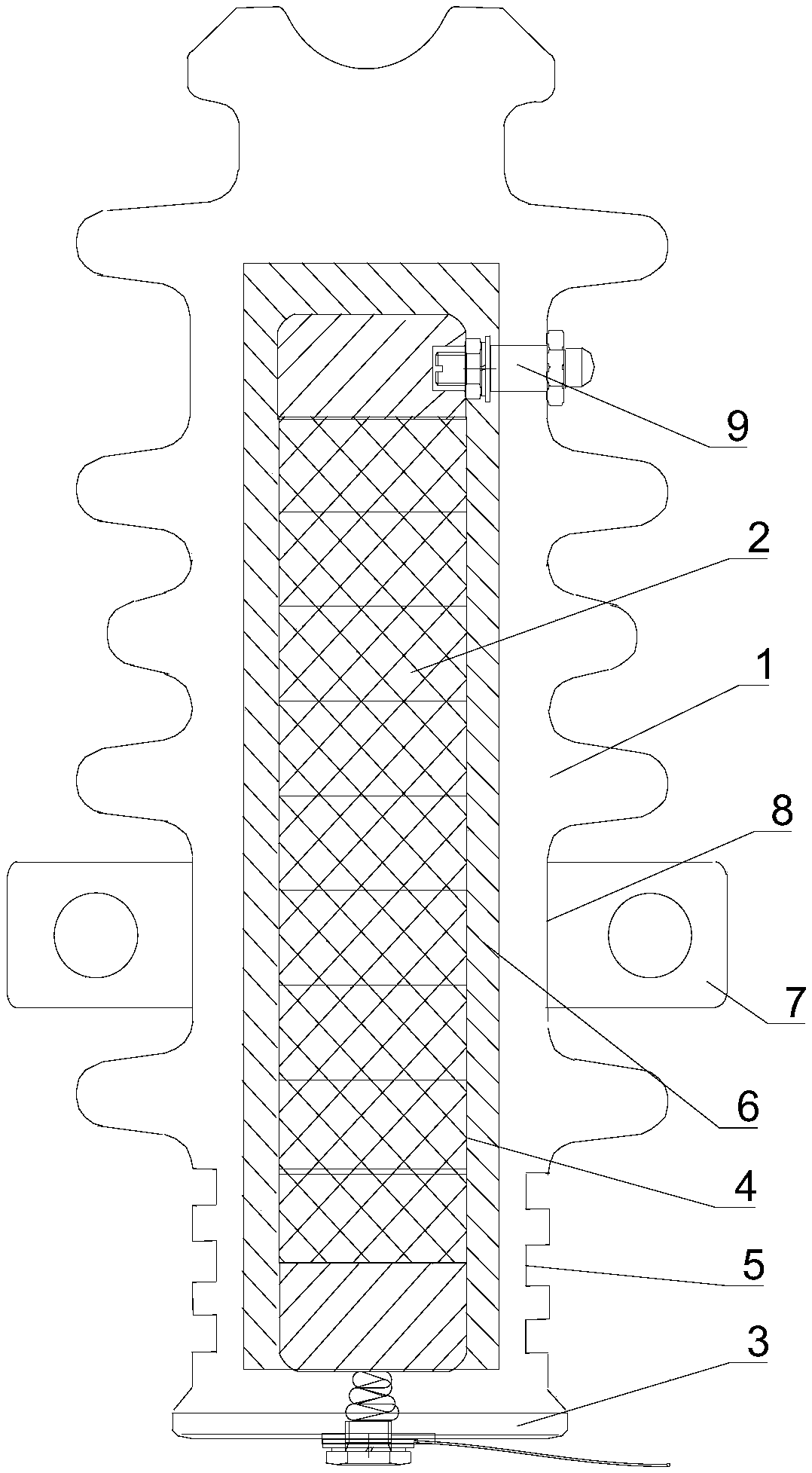

[0032] Such as figure 1 As shown, a visible fault lightning arrester includes a lightning arrester porcelain casing 1, a mandrel 2 and a cover 3. The interior of the lightning arrester porcelain casing 1 is provided with an inner cavity 4 for accommodating the mandrel 2. In the lightning arrester porcelain casing 1 There are three axially distributed annular grooves 5 on the outer periphery of one end close to the opening of the inner cavity 4. The thickness and strength of the annular grooves 5 are lower than those of other parts of the lightning arrester sleeve 1; the cross-sectional shape of the annular grooves 5 is a rectangle. The core is put into the inner cavity 4 of the lightning arrester porcelain sleeve 1 and the gap in the inner cavity 4 is filled with adhesive to form an adhesive layer 6. The adhesive layer 6 is used for sealing and preventing the lightning arrester porcelain sleeve 1 from exploding. Splash of fragments is generated; a high-voltage electrode 9 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com