Modification method for involute spline relief grinding wheel

A technology of involute splines and grinding wheels, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding automatic control devices, etc. It can solve the problems of inconvenient use, inability to manually modify, and inability to manually modify G codes, etc. problems, to achieve the effect of improving molding rate and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the characteristics, technical means and specific functions achieved by the present invention, the present invention will be further described in detail below with specific implementation modes.

[0027] This embodiment provides a method for modifying the shape of an involute spline shovel grinding wheel, and the specific method steps are as follows:

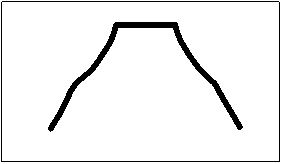

[0028] S1: Draw up the parameters of the spline on the control panel, and automatically fit the contour shape of the grinding wheel through the parameters given by the spline. The contour diagram is as follows figure 2 shown;

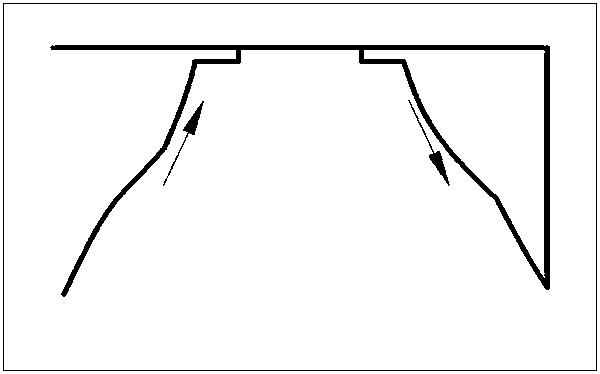

[0029] S2: Select the part that needs to be modified after fitting the contour of the grinding wheel, so as to determine whether the diamond wheel is a local modification or a global modification of the grinding wheel;

[0030] S3: After selecting the contour of the grinding wheel and clicking on the control panel to generate G code, the generated G code is saved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com