Road crack repair and cleaning machine

A technology of crack repairing and cleaning machine, which is applied in the field of crack repairing and cleaning, which can solve the problems of staying in cracks, cleaning fatigue, poor cleaning effect, etc., and achieve the effect of reducing labor intensity and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

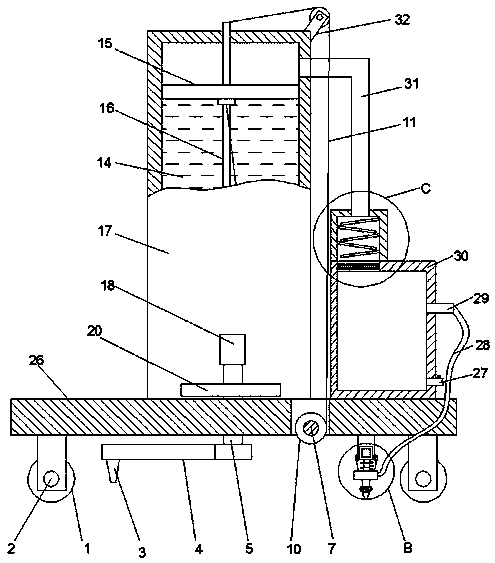

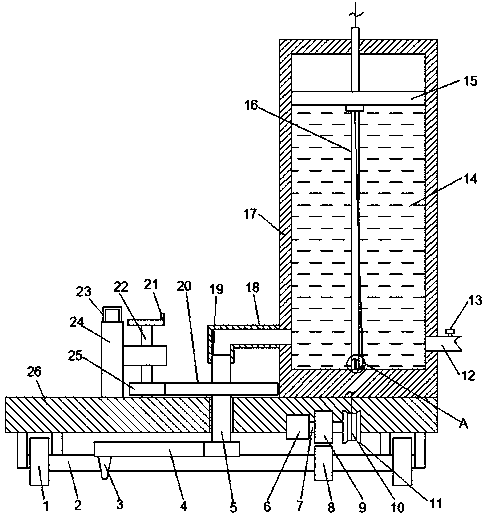

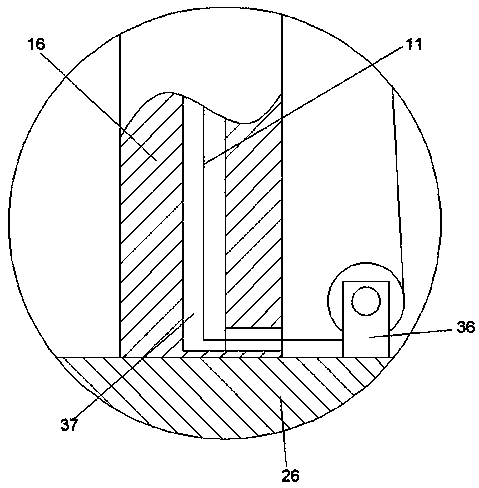

[0038] refer to figure 1 , figure 2 and Figure 7 , a road crack repairing and cleaning machine, comprising a mobile base 26, a water cylinder 17 is fixedly connected to the mobile base 26, a vertical water pipe 5 is rotatably connected to the mobile base 26, and a horizontal water pipe 4 is fixedly connected to the lower end of the vertical water pipe 5 , the end of the horizontal water pipe 4 away from the vertical water pipe 5 is fixedly connected with a high-pressure nozzle 3, the lower end of the water cylinder 17 is connected with a water outlet pipe 18, and the end of the water outlet pipe 18 away from the water cylinder 17 is connected to the upper end of the vertical water pipe 5 in a rotating and sealed manner. The base 26 is fixedly connected with a water cylinder 17, and the water cylinder 17 delivers water through the vertical water pipe 5 and the horizontal water pipe 4 and the high-pressure nozzle 3, while the vertical water pipe 5 is rotatably connected to th...

Embodiment 2

[0040] refer to figure 1 and figure 2, a road crack repairing and cleaning machine, which is basically the same as that of Embodiment 1, the difference is that a sealing ring 19 is connected to the joint between the vertical water delivery pipe 5 and the water outlet pipe 18, and the lower end of the water cylinder 17 is connected to the water supply pipe 12, and the water supply pipe 12 It is connected with a water adding valve 13, and clear water 14 is filled in the water cylinder 17. The sealing joint between the vertical water delivery pipe 5 and the water outlet pipe 18 is effectively sealed by the sealing ring 19. Add fresh water 14.

Embodiment 3

[0042] refer to figure 1 , figure 2 and Figure 7 , a road crack repairing and cleaning machine, comprising a mobile base 26, a water cylinder 17 is fixedly connected to the mobile base 26, a vertical water pipe 5 is rotatably connected to the mobile base 26, and a horizontal water pipe 4 is fixedly connected to the lower end of the vertical water pipe 5 , the end of the horizontal water pipe 4 away from the vertical water pipe 5 is fixedly connected with a high-pressure nozzle 3, the lower end of the water cylinder 17 is connected with a water outlet pipe 18, and the end of the water outlet pipe 18 away from the water cylinder 17 is connected to the upper end of the vertical water pipe 5 in a rotating and sealed manner. The base 26 is fixedly connected with a water cylinder 17, and the water cylinder 17 delivers water through the vertical water pipe 5 and the horizontal water pipe 4 and the high-pressure nozzle 3, while the vertical water pipe 5 is rotatably connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com