Elevated station

A technology for stations and viaducts, which is applied to bridge parts, safety islands, public buildings, etc. It can solve the problems of large substructure size, large volume, self-heaviness of cast-in-place concrete structures, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

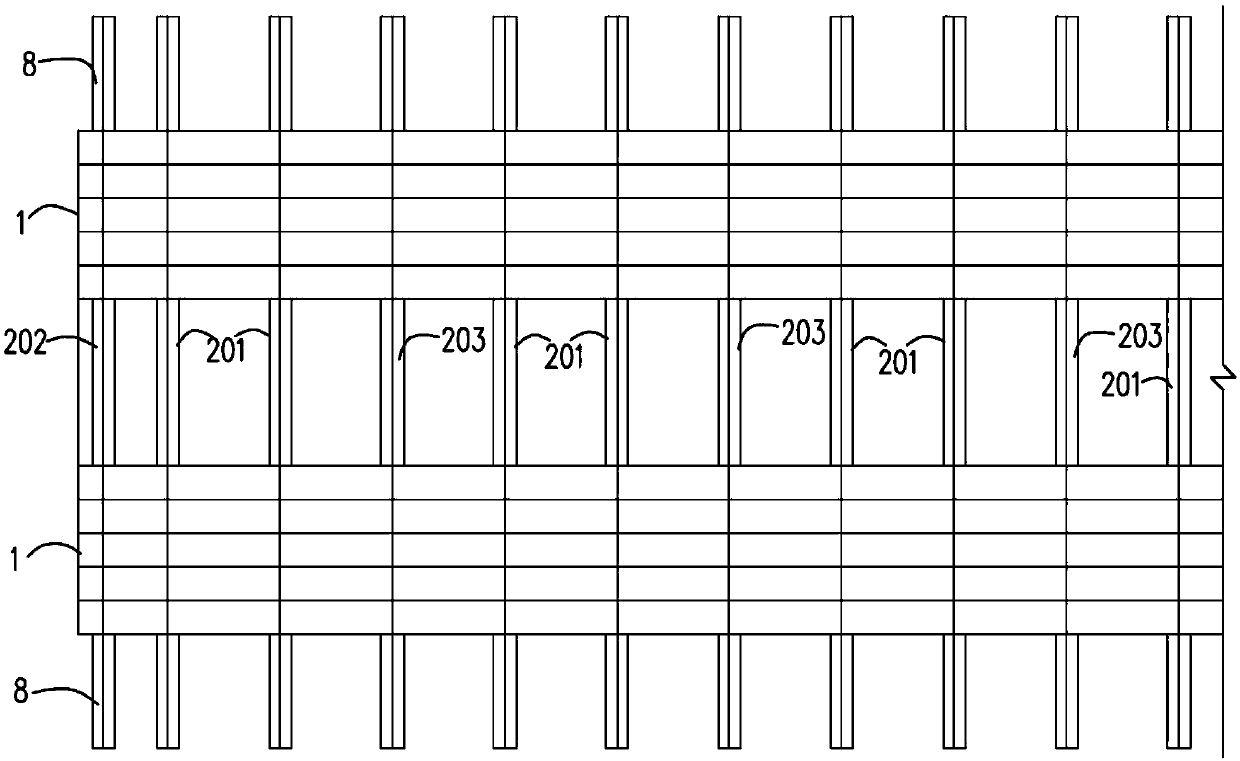

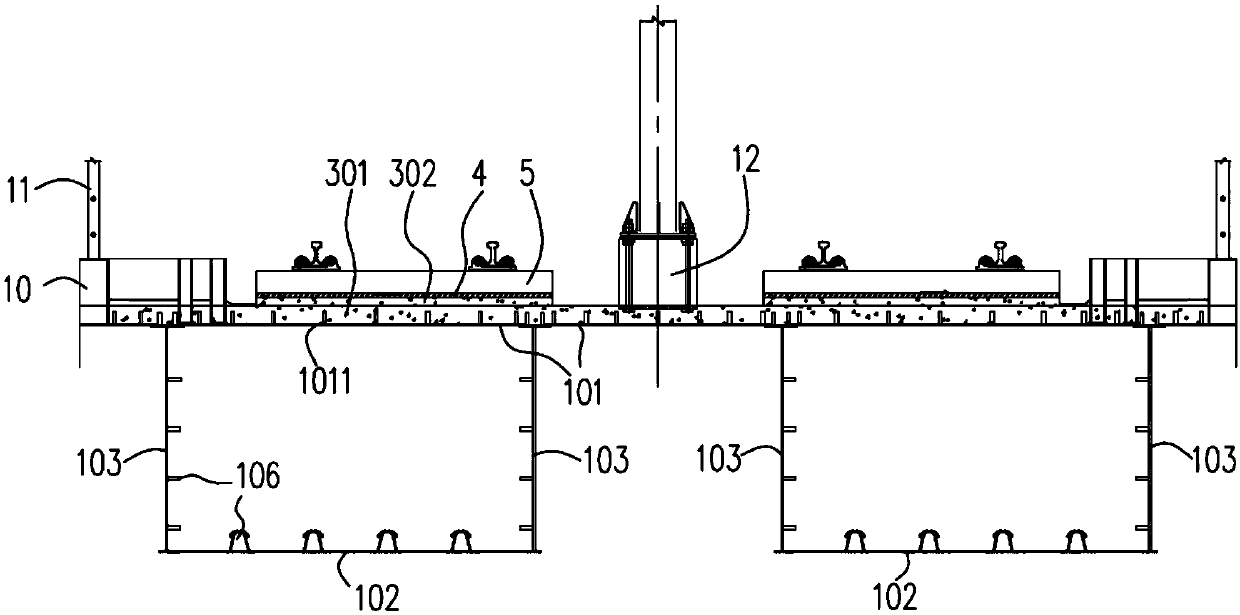

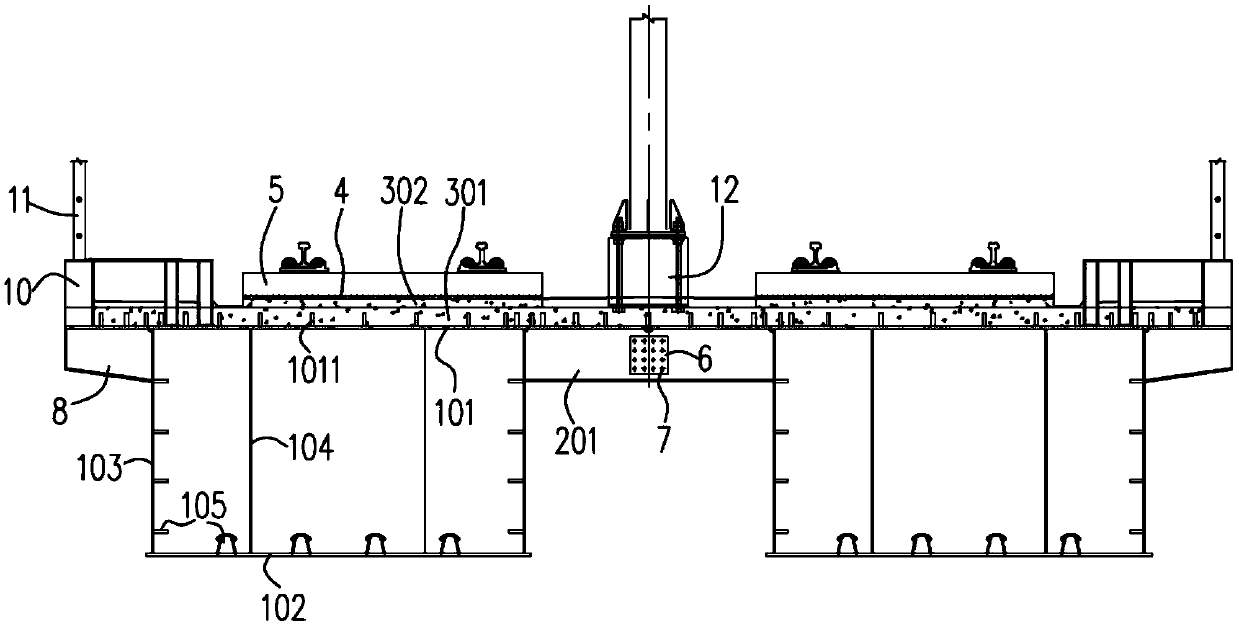

[0034] like Figure 1-Figure 6 , the embodiment of the present invention provides an elevated steel-concrete composite beam, including at least two separated steel boxes 1, each of which includes a box top plate 101, a box bottom plate 102 and two webs 103, the The box roof 101, the box bottom 102 and the two webs 103 are connected to form a box structure, and each of the box roofs 101 is poured with a concrete layer; each of the separated steel boxes 1 is arranged in sequence along the beam transverse direction, each Two adjacent separated steel boxes 1 are spliced by a cross-connection mechanism. The cross-connection mechanism includes a plurality of cross-connection groups arranged in sequence along the longitudinal direction of the beam. 6 and bolts 7 are sequentially spliced with a plurality of cross-connecting plates, and each of the cross-connecting plates is respectively connected to the box roof 101 of the corresponding separated steel box 1. Wherein, it is easy ...

Embodiment 2

[0057] like Figure 7-Figure 10An embodiment of the present invention provides an elevated station, including a superstructure and a substructure 2000, the substructure 2000 supports the superstructure, wherein the superstructure includes a viaduct 1000, a platform slab 5000 arranged on the viaduct 1000 and For the canopy 6000, the elevated beam 1000 is preferably the elevated steel-concrete composite beam provided in the first embodiment above, and the structure of the elevated steel-concrete composite beam will not be repeated here.

[0058] like Figure 8-Figure 10 , preferably, the elevated girder 1000 adopts a cross-connection group structure including three cross-connection plates and the two joints are respectively close to the corresponding two separate steel boxes 1, so that the station structure is stable and reliable.

[0059] like Figure 8 and Figure 9 , preferably, the elevated beam 1000 adopts a structure in which the two lateral sides of the beam are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com