I-shaped energy dissipation connecting part for coupled shear wall structure

A technology of connectors and shear walls, which is applied in the direction of building components, building types, building structures, etc., can solve the problems of high maintenance costs, achieve the effects of protecting the main structure, excellent energy consumption capacity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

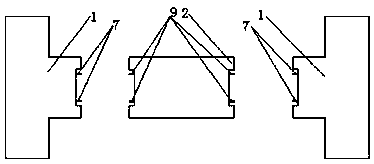

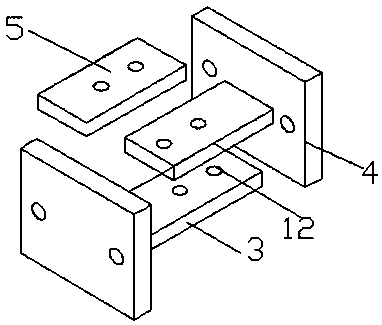

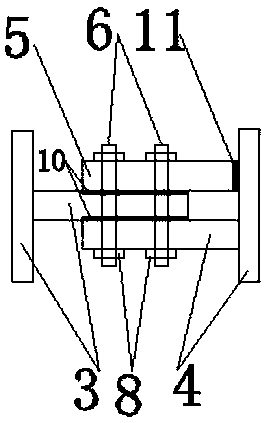

[0024] Examples such as Figure 1-Figure 7 As shown, during construction, after the assembly of the shear wall plinth 1 is completed, the replaceable coupling beam 2 of the shear wall pier 1 is assembled. First, one side of the T-shaped connector-3 is connected to the shear wall wall The pre-embedded anchor bar 7 inside the limb 1 fixes the T-shaped connector one 3 on the end of the shear wall wall limb 1 through the nut 8, and then one side of the T-shaped connector two 4 is connected to the inner part of the replaceable coupling beam 2 Pre-embed the steel bar 9, fix the T-shaped connector 2 4 on the end of the replaceable connecting beam 2 through the nut 8, and then fix the other side of the T-shaped conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com