Hydraulic driving system of big arm of heavy railway wagon

A drive system and arm technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the inconvenience of installation and debugging and fault analysis and troubleshooting, complex and fragmented management of hydraulic system valves, hydraulic system Problems such as high energy consumption can achieve the effect of reducing energy consumption, reducing pressure loss, and ensuring stable landing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

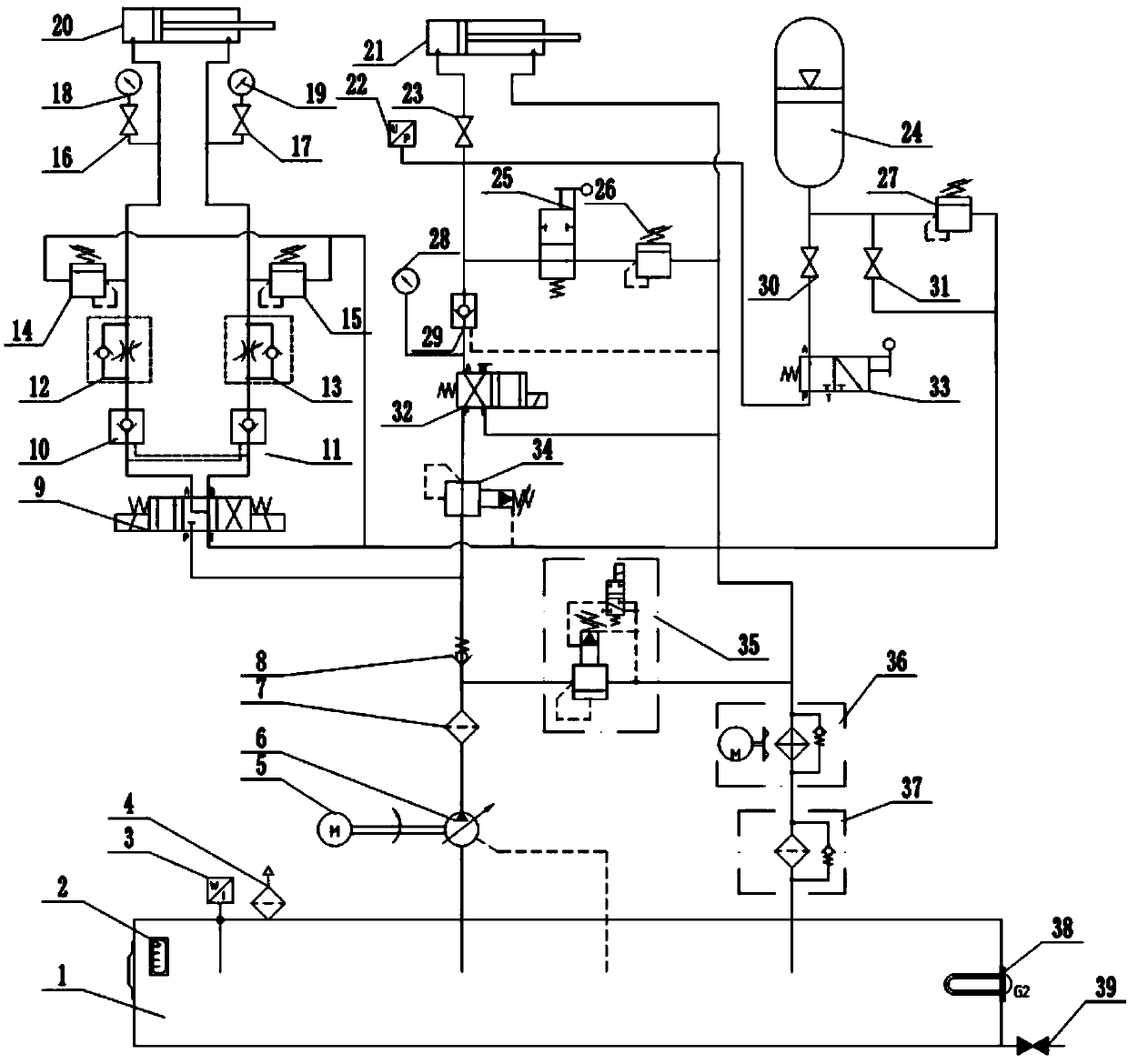

[0024] The utility model relates to a hydraulic drive system of a large arm of a readjustment machine. Such as figure 1 As shown, the boom hydraulic drive system of the readjustment machine includes a hydraulic pump station, a drive cylinder circuit, a balance cylinder circuit and a balance cylinder oil supply circuit. The hydraulic pump station is connected with the driving cylinder circuit and the balance cylinder circuit through the hydraulic pipeline, and the oil supply circuit of the balance cylinder is connected with the balance cylinder circuit through the hydraulic pipeline.

[0025] Such as figure 1 As shown, the hydraulic pump station includes an oil tank 1 , a motor 5 , a hydraulic pump 6 , a one-way valve 8 , a pilot electromagnetic overflow valve 35 and a condenser 36 . The motor 5 is connected to the hydraulic pump 6 shaft, the oil outlet of the hydraulic pump 6 is connected to the oil inlet of the filter 7, the oil outlet of the filter 7 is connected to the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com