Auto-cascading refrigeration cycle system and refrigeration cycle method both synergized by using double injectors

A cycle system and ejector technology, which is applied in the field of self-cascading refrigeration cycle system and refrigeration cycle, can solve the problems of poor load adaptability, failure, and boost failure of ejector, so as to enhance load adaptability, enhance work stability, The effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

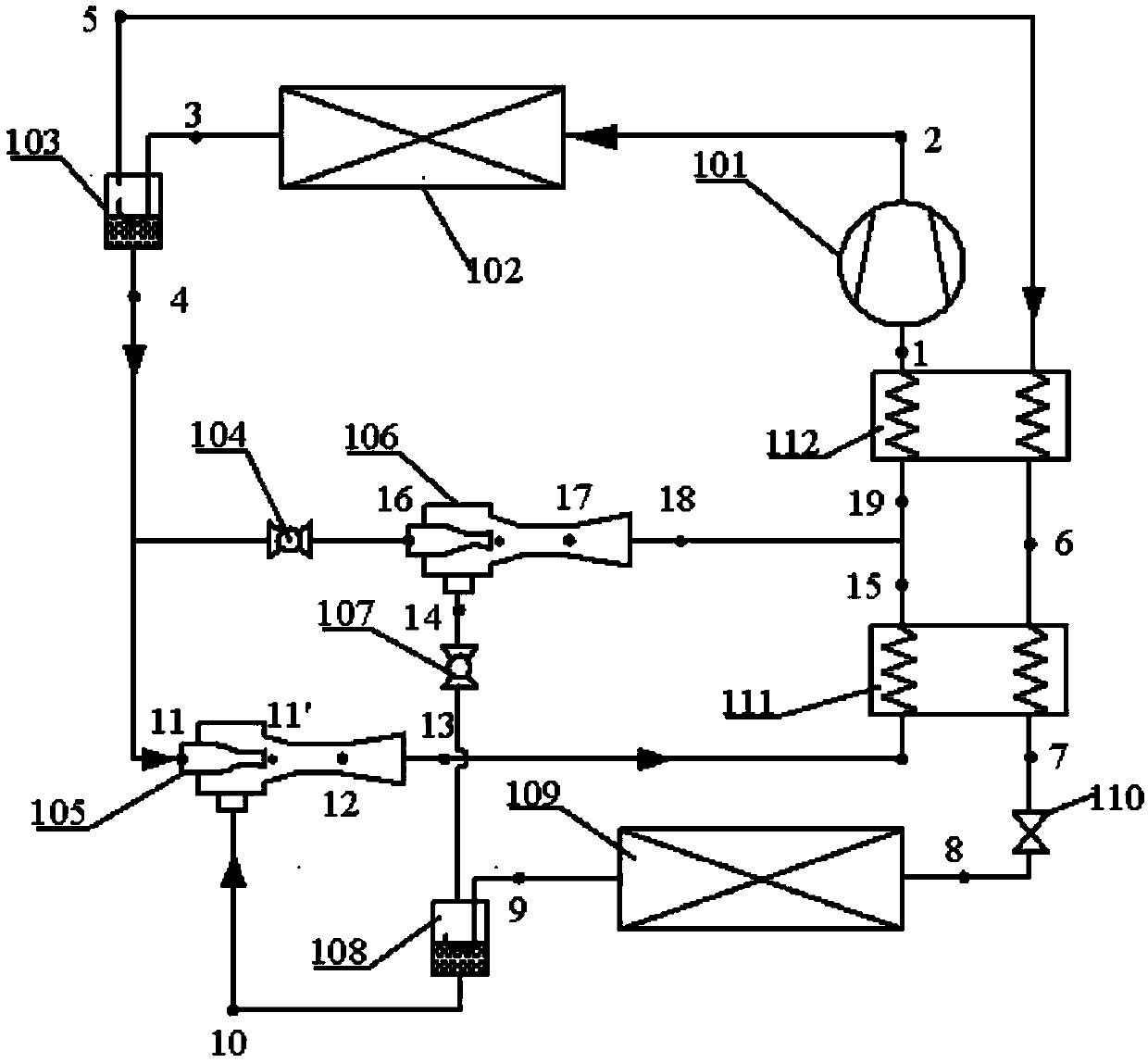

[0012] like figure 1 As shown, in this embodiment, a self-cascading dual-temperature refrigeration system using ejector synergies includes a compressor 101, the outlet of the compressor 101 is connected to the inlet of the condenser 102, and the outlet of the condenser 102 is connected to the gas-liquid separator The inlet of I103 is connected; the saturated liquid of gas-liquid separator I103 is divided into two paths: one path is connected with the nozzle inlet of injector I105, and the other path is connected with control ball valve 104 and the nozzle of injector II106 in turn; the saturated gas of gas-liquid separator I103 The outlet is connected to the inlet of the condensing side of the evaporative condenser I112, the outlet of the condensing side of the evaporative condenser I112 is connected to the inlet of the condensing side of the evaporative condenser II111, and the outlet of the condensing side of the evaporative condenser II111 is connected to the throttling mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com