Electronic device junction temperature measurement method and device

A technology of electronic devices and measuring devices, which is applied in the field of semiconductor device junction temperature measurement, can solve problems such as differences, and achieve the effect of simple test principle, simple implementation method, and wide range of effective measurable objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

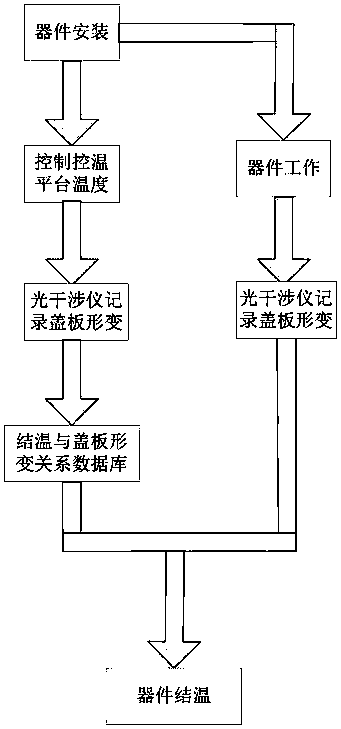

[0031] 1) Construction of junction temperature measurement system

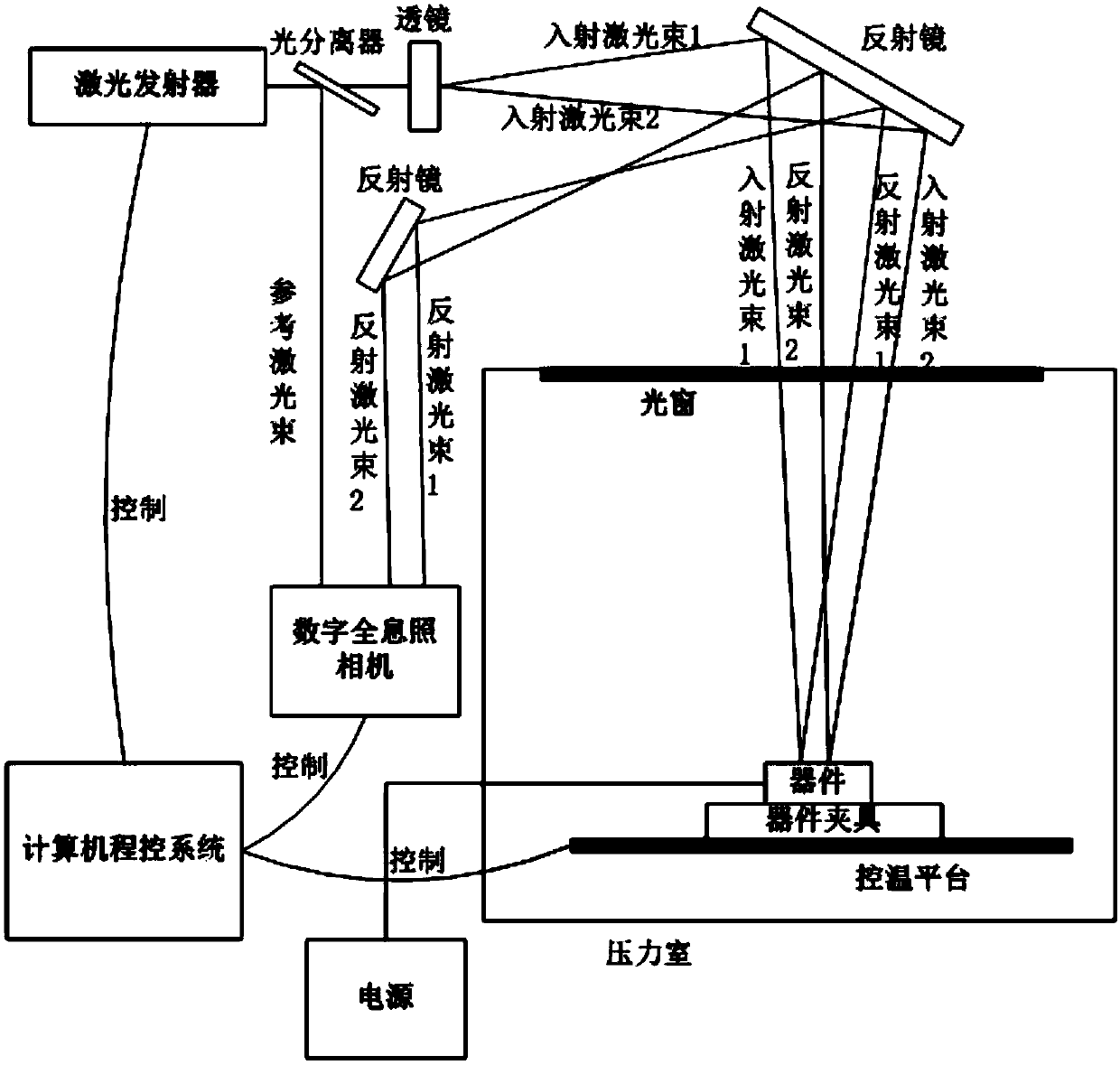

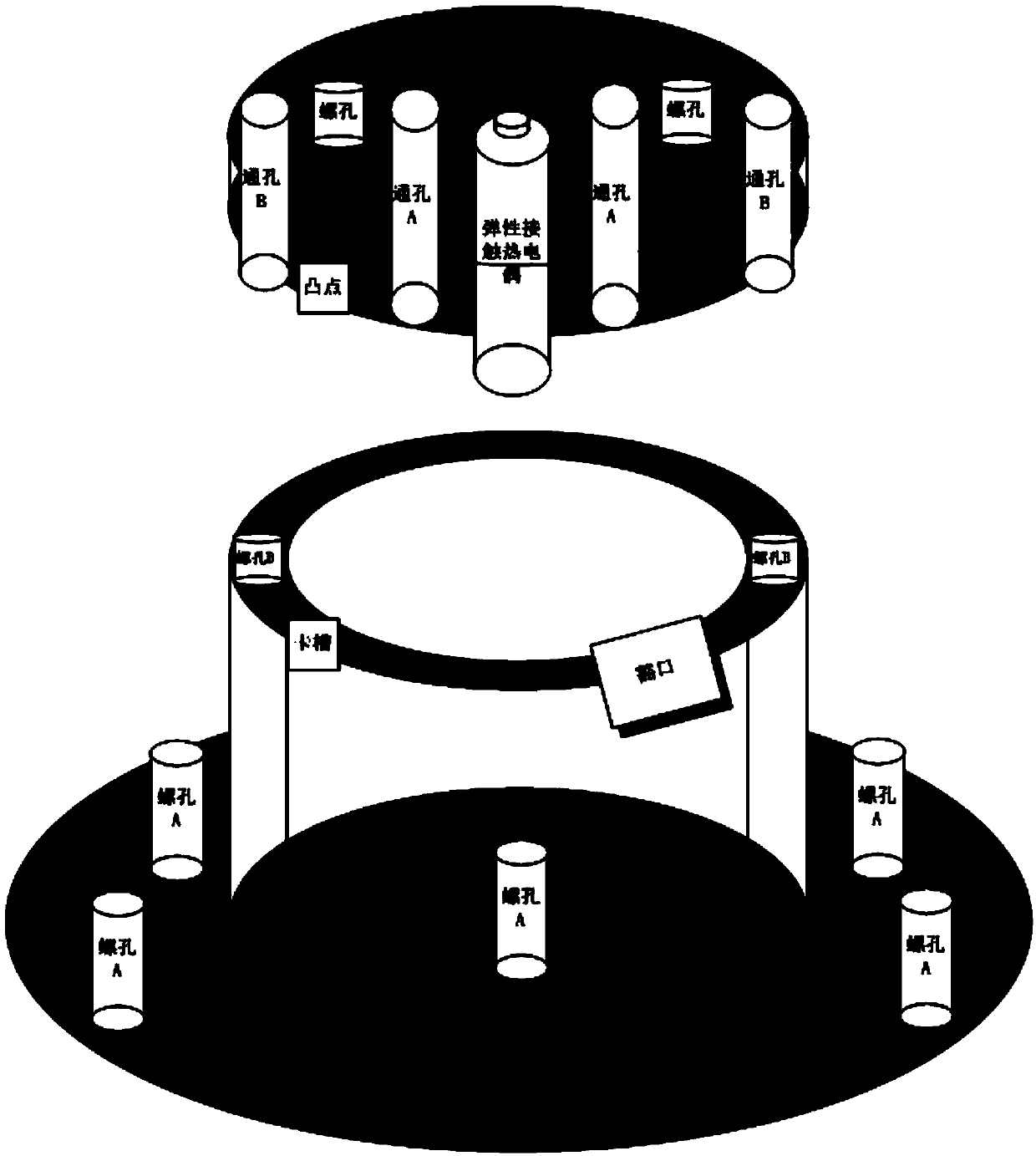

[0032] figure 1 is a schematic diagram of the junction temperature measurement system built as described in this embodiment, as shown in figure 1 As shown, the junction temperature measurement system includes: pressure chamber, laser interferometer, temperature control platform, device fixture, power supply, computer control and calculation system.

[0033] The pressure chamber can ensure the pressure is stable and will not affect the accuracy of the deformation measurement of the cover due to the change of the ambient atmospheric pressure; the laser interferometer records the reference laser beam under different conditions and the laser reflected by the device cover through the digital holographic system The beam forms an interference image, so that the deformation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com