Graphene oxide/carbon nitride/bismuth oxyiodide composite material, and preparation method and applications thereof

A technology of bismuth iodide and composite materials, which is applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve the problems of low antibacterial effect, limited application of bismuth iodide monomer, and high recombination rate, and achieves the preparation method. Simple and easy, high application prospect and practical value, the effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

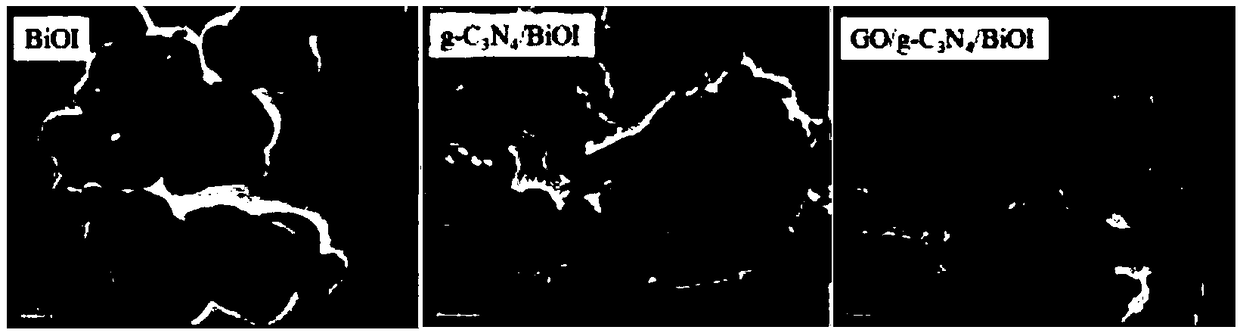

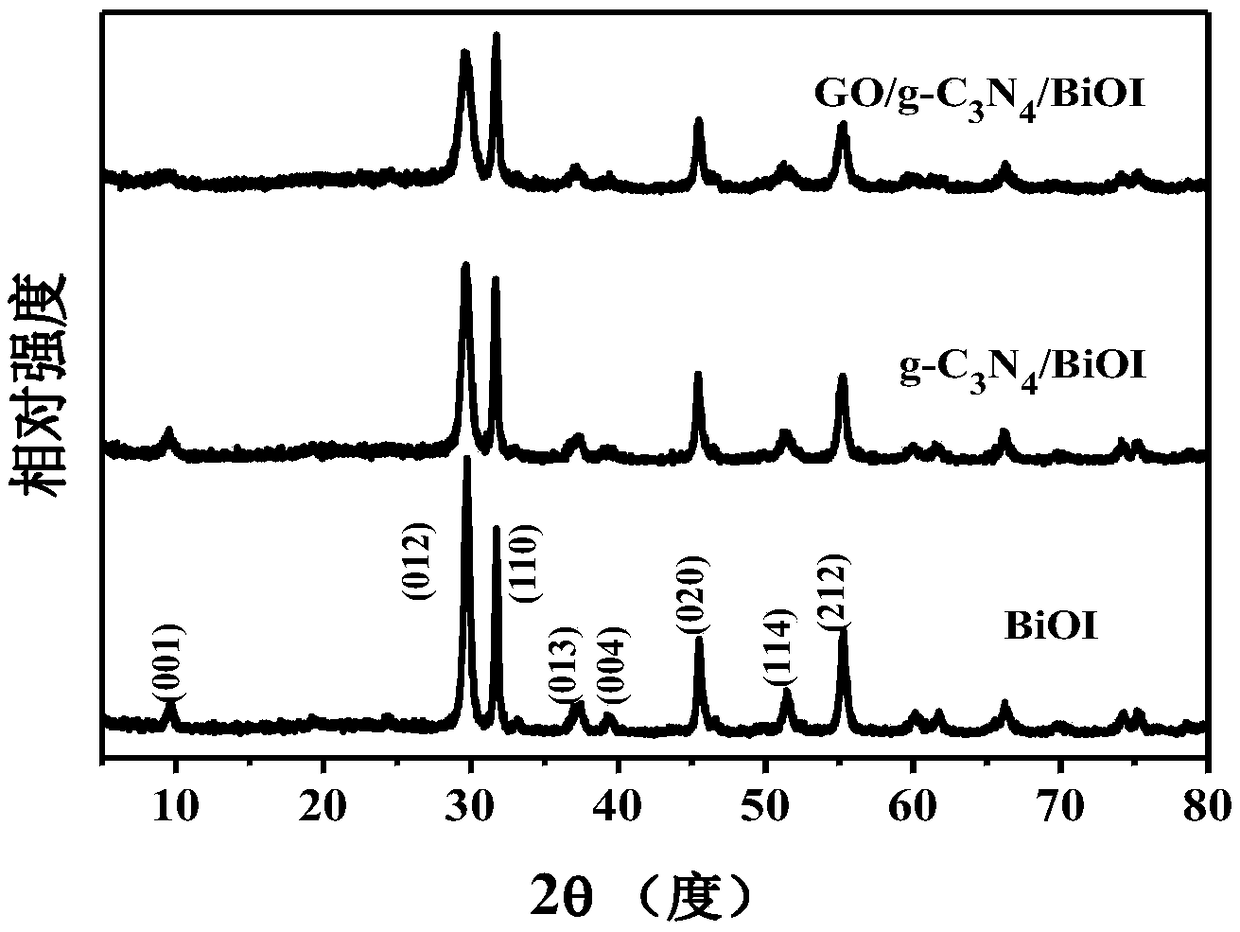

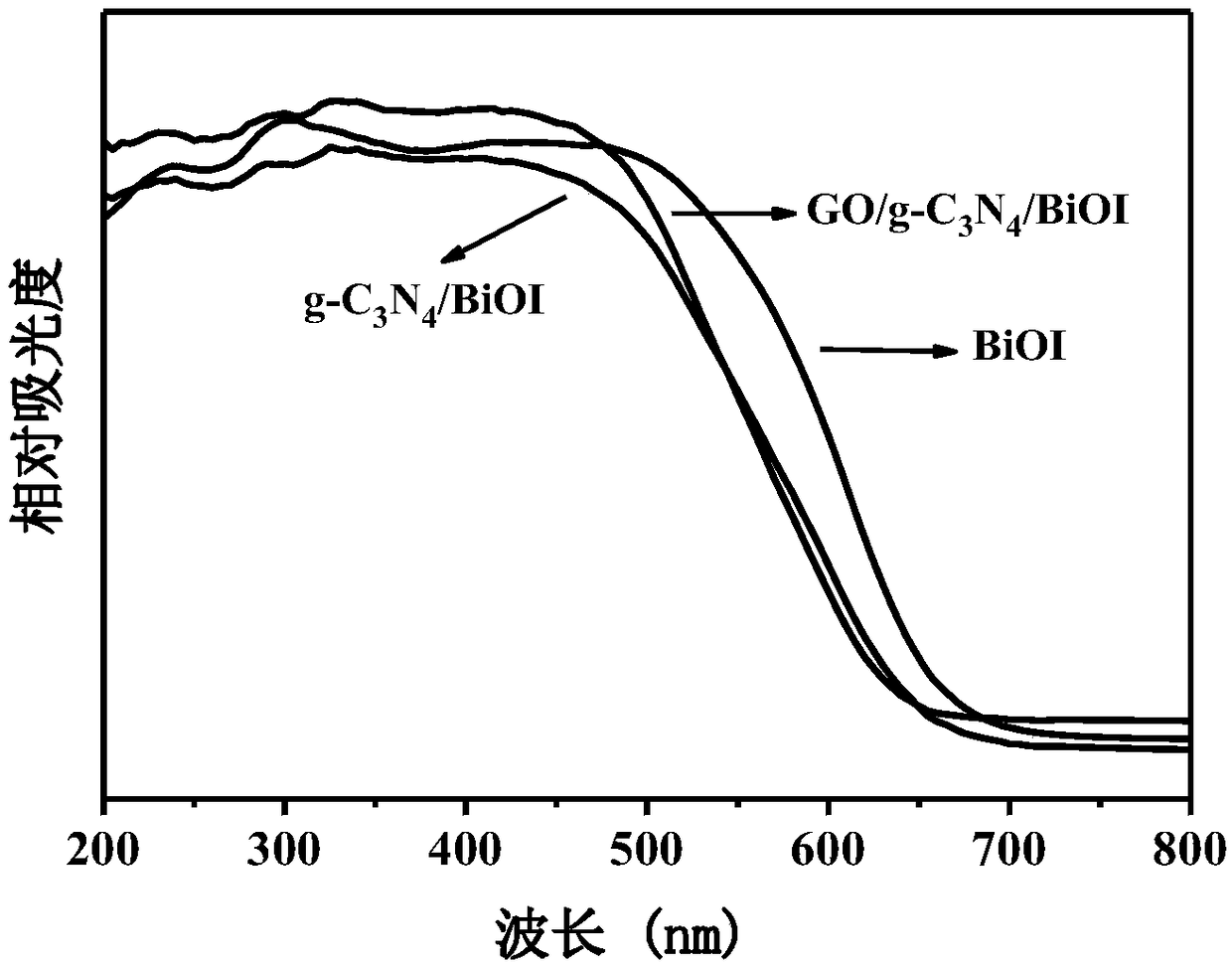

[0025] Preparation of bismuth iodide oxide (BiOI): weigh 0.332g of potassium iodide and dissolve in 40mL of distilled water to prepare potassium iodide solution; weigh 0.97g of bismuth nitrate pentahydrate and dissolve in 30mL of ethylene glycol to prepare bismuth nitrate pentahydrate in ethylene glycol solution; The potassium iodide solution was dropped into the bismuth nitrate pentahydrate ethylene glycol solution, stirred at room temperature for 60 minutes, washed with water, and the resulting precipitate was dried in an oven at 60° C., and ground, as the reference BiOI.

[0026] Carbon nitride (g-C 3 N 4 ) Preparation: Weigh 4.0g urea, calcinate in a muffle furnace at 520℃ for 4h, cool and grind to obtain g-C 3 N 4 .

[0027] Carbon nitride / bismuth iodide (g-C 3 N 4 / BiOI) Preparation: Weigh 0.332g of potassium iodide and dissolve it in 40mL of distilled water, add 0.176g of g-C 3 N 4 , Disperse it by ultrasound (denoted as solution A); weigh out 0.97g of bismuth nitrate pentahy...

Example Embodiment

[0028] Example 1:

[0029] g-C 3 N 4 Preparation: Weigh 4.0g of urea, calcined in a muffle furnace at 550℃ for 3h, cool and grind to obtain g-C 3 N 4 .

[0030] GO / g-C 3 N 4 / BiOI preparation: Weigh 0.332g of potassium iodide and dissolve it in 41mL of distilled water, add 0.47mL of graphene oxide (GO) solution (1mg / mL) and 0.235g of g-C to it 3 N 4 Disperse it by ultrasound to prepare a suspension solution; weigh out 0.97g of bismuth nitrate pentahydrate and dissolve it in 38.8mL ethylene glycol solution to prepare a ethylene glycol solution of bismuth nitrate pentahydrate; drop the suspension solution into nitric acid pentahydrate In the bismuth glycol solution, stirred at room temperature for 90 minutes, the resulting precipitate was washed with water, dried in an oven at 60°C, and ground to obtain a graphene oxide / carbon nitride / iodine bismuth oxide composite material, including graphene oxide, carbon nitride, and iodine The mass percentages of bismuth oxide are 0.05%, 25%, and...

Example Embodiment

[0032] Example 2:

[0033] g-C 3 N 4 Preparation: Weigh 4.0g of urea, calcinate in a muffle furnace at 520℃ for 5h, cool and grind to obtain g-C 3 N 4 .

[0034] GO / g-C 3 N 4 / BiOI preparation: Weigh 0.332g potassium iodide and dissolve in 22.7mL distilled water, add 7.49mL GO solution (1mg / mL) and 0.037g g-C to it 3 N 4 Disperse it by ultrasound to prepare a suspension solution; weigh 0.97g of bismuth nitrate pentahydrate and dissolve it in 24.3 mL of ethylene glycol solution to prepare a ethylene glycol solution of bismuth nitrate pentahydrate; drop the suspension solution into nitric acid pentahydrate In the bismuth glycol solution, stirred at room temperature for 60 minutes, the resulting precipitate was washed with water, dried in an oven at 90°C, and ground to obtain a graphene oxide / carbon nitride / iodine bismuth oxide composite material, including graphene oxide, carbon nitride, and iodine The mass percentage of bismuth oxide is 1%, 5%, and 94%.

[0035] GO / g-C obtained in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com