Reinforced steel bar end portion polishing mechanism and reinforced steel bar machining device

A technology for grinding mechanisms and steel bars, which is applied in the direction of grinding drive devices, grinding workpiece supports, metal processing equipment, etc., to achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

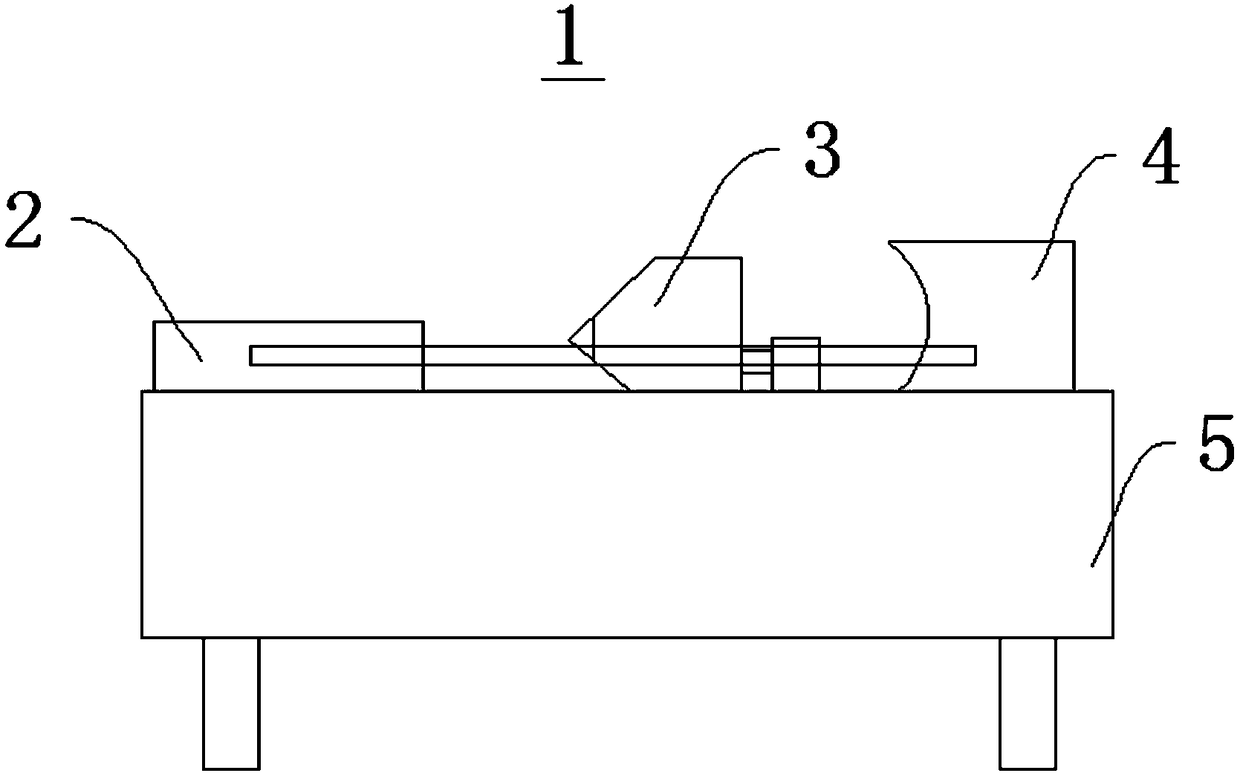

[0033] This embodiment provides a steel bar processing device, which includes a steel bar end grinding mechanism 1, which is mainly used for rapidly grinding the deformed and punctured ends.

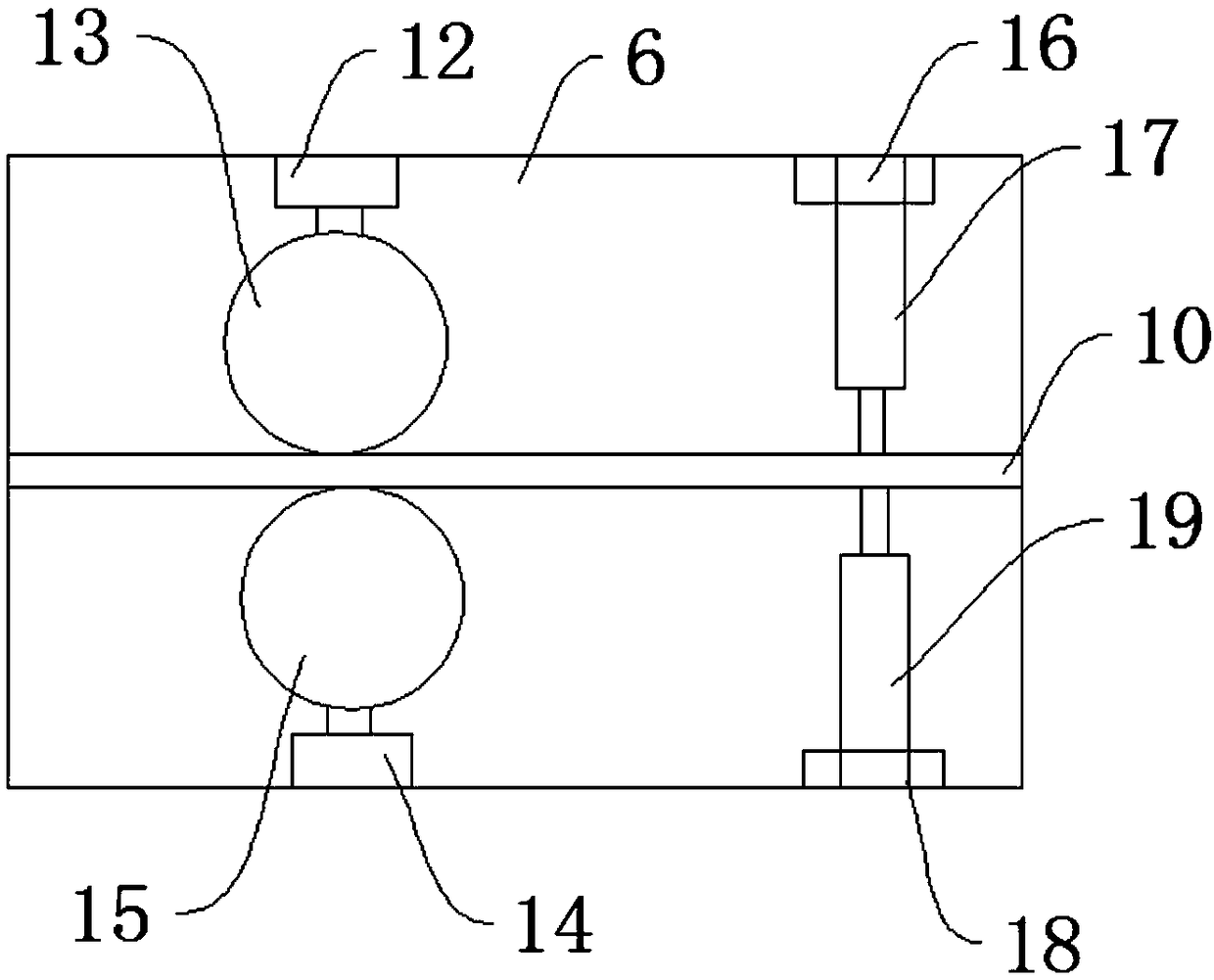

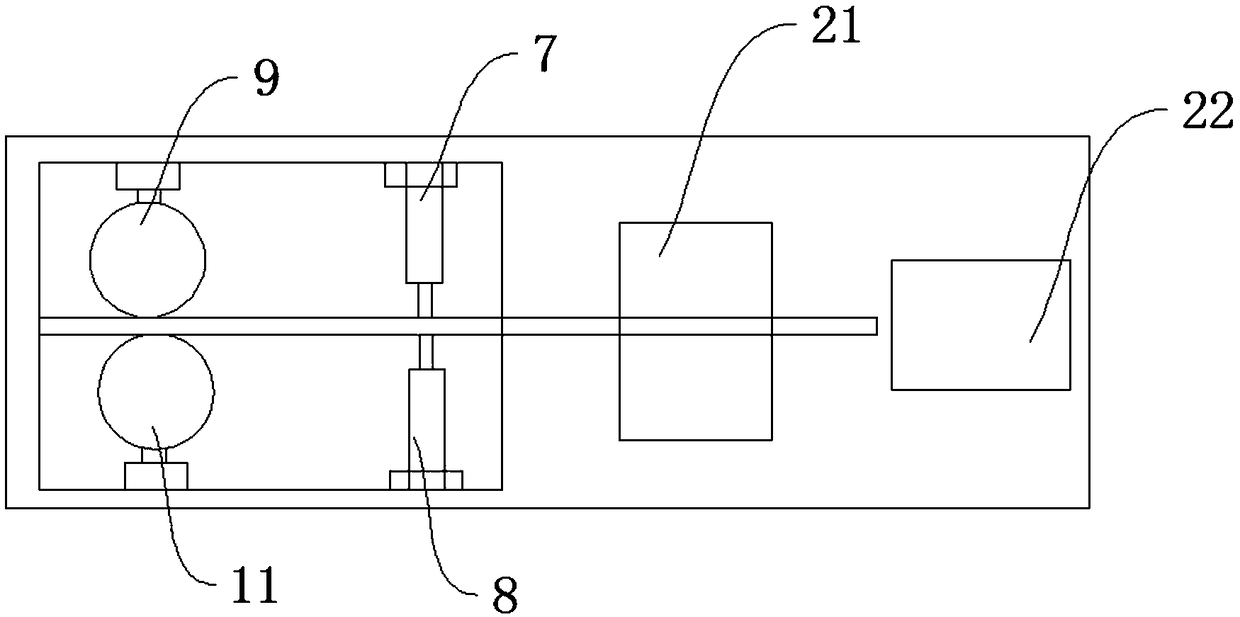

[0034] see Figure 1 to Figure 4 , the steel bar end grinding mechanism 1 includes a positioning fixture 2, a grinding assembly 3, a grinding assembly 4 and a support frame 5; the positioning fixture 2 includes a positioning plate 6, a first clamp 7, a second clamp 8, a first driver 9 and the second driver 11; the positioning plate 6 is provided with a chute 10 in the axial direction, the first clamp 7 and the second clamp 8 are respectively installed on both sides of the chute 10, and the first driver 9 is installed The second driver 11 is respectively installed on one side of the chute 10 opposite to the chute 10, and the steel bar to be processed is arranged in the chute 10; , the grinding assembly 3 and the grinding assembly 4 are on the same straight line; the first driver 9 can dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com