Improved multicolor light-reflecting printing and dyeing method

An improved, reflective technology, applied in the field of printing and dyeing, can solve the problems of cumbersome operation, no process parameters, simple steps, etc., and achieve the effect of fast ink supply, high space utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

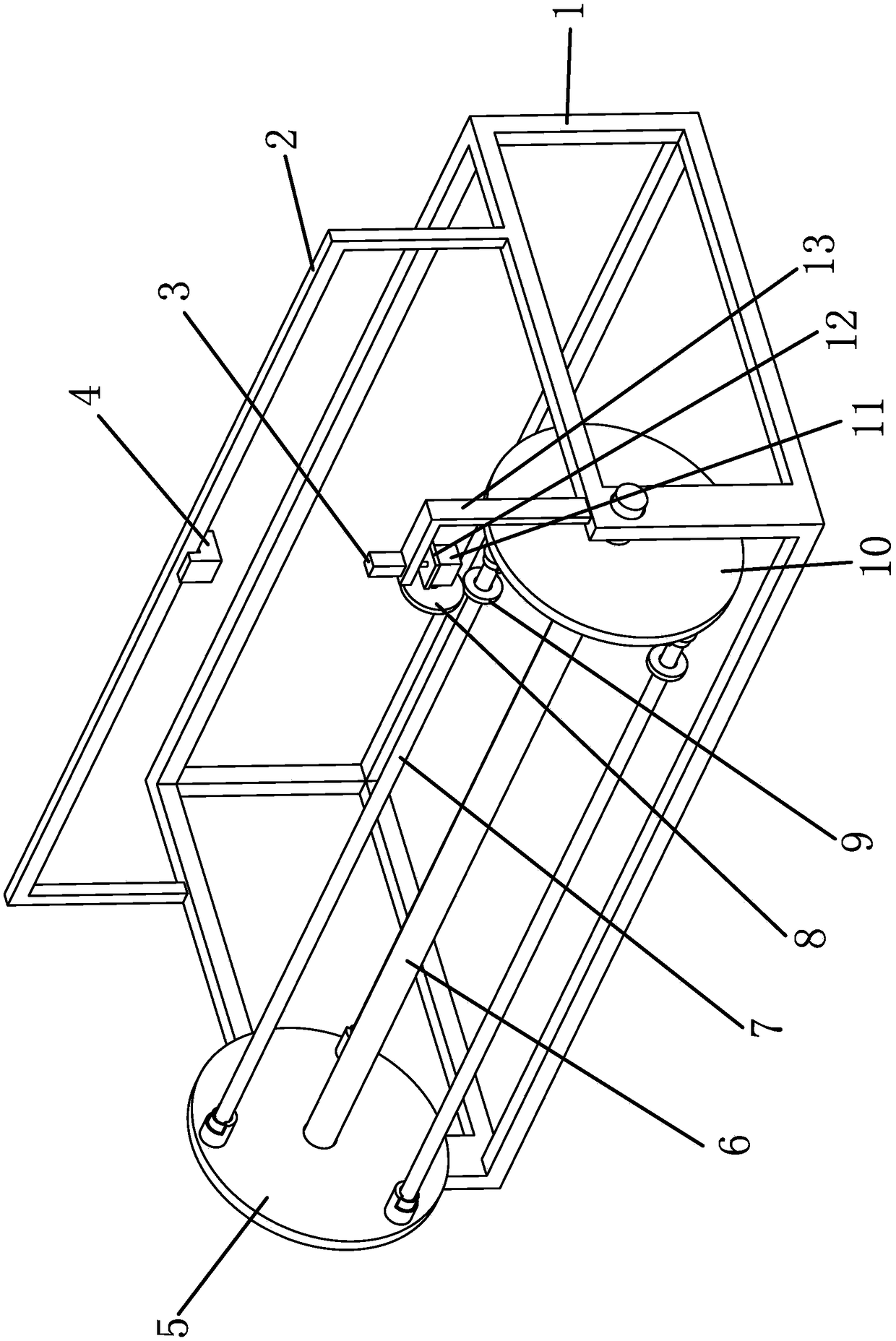

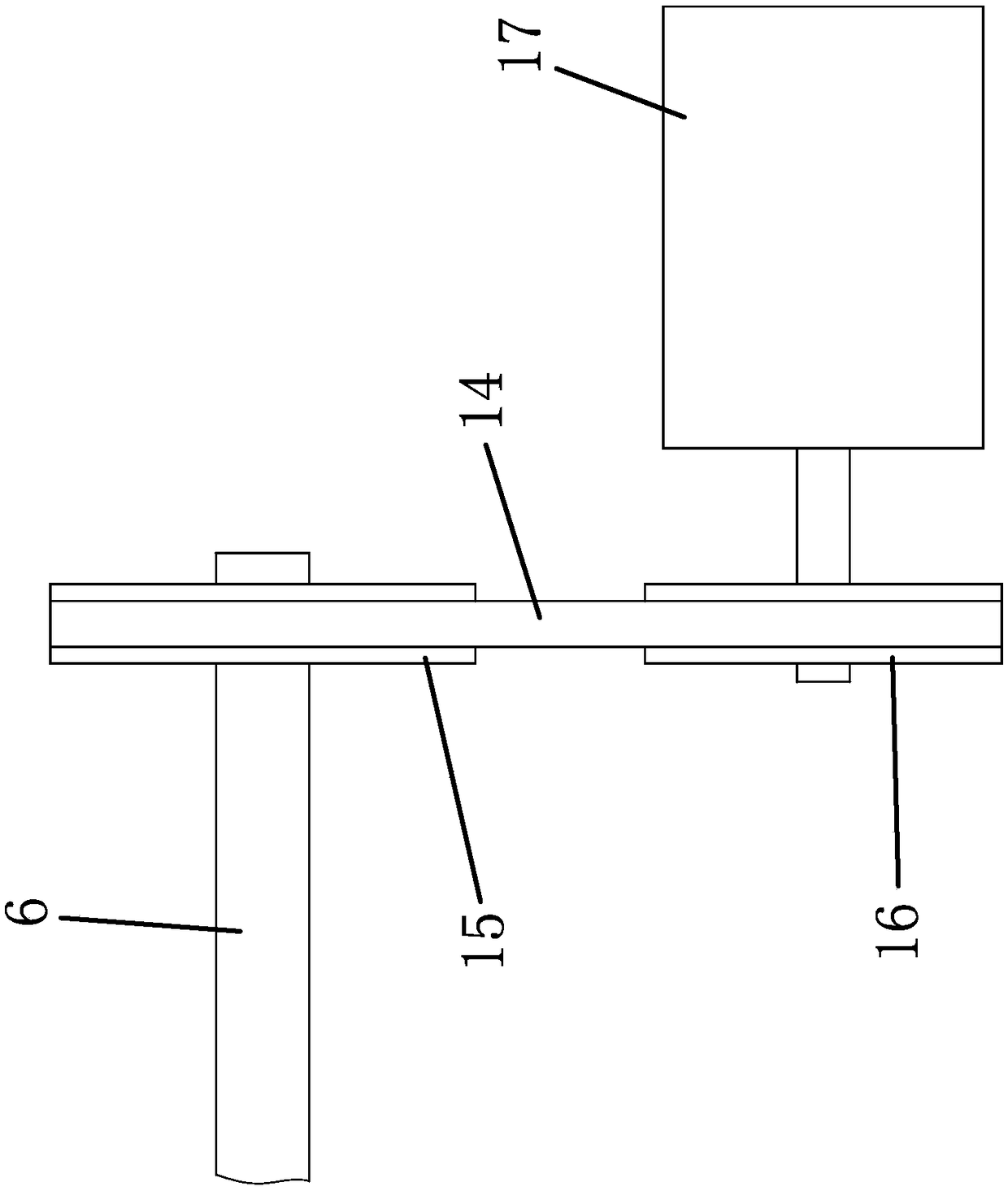

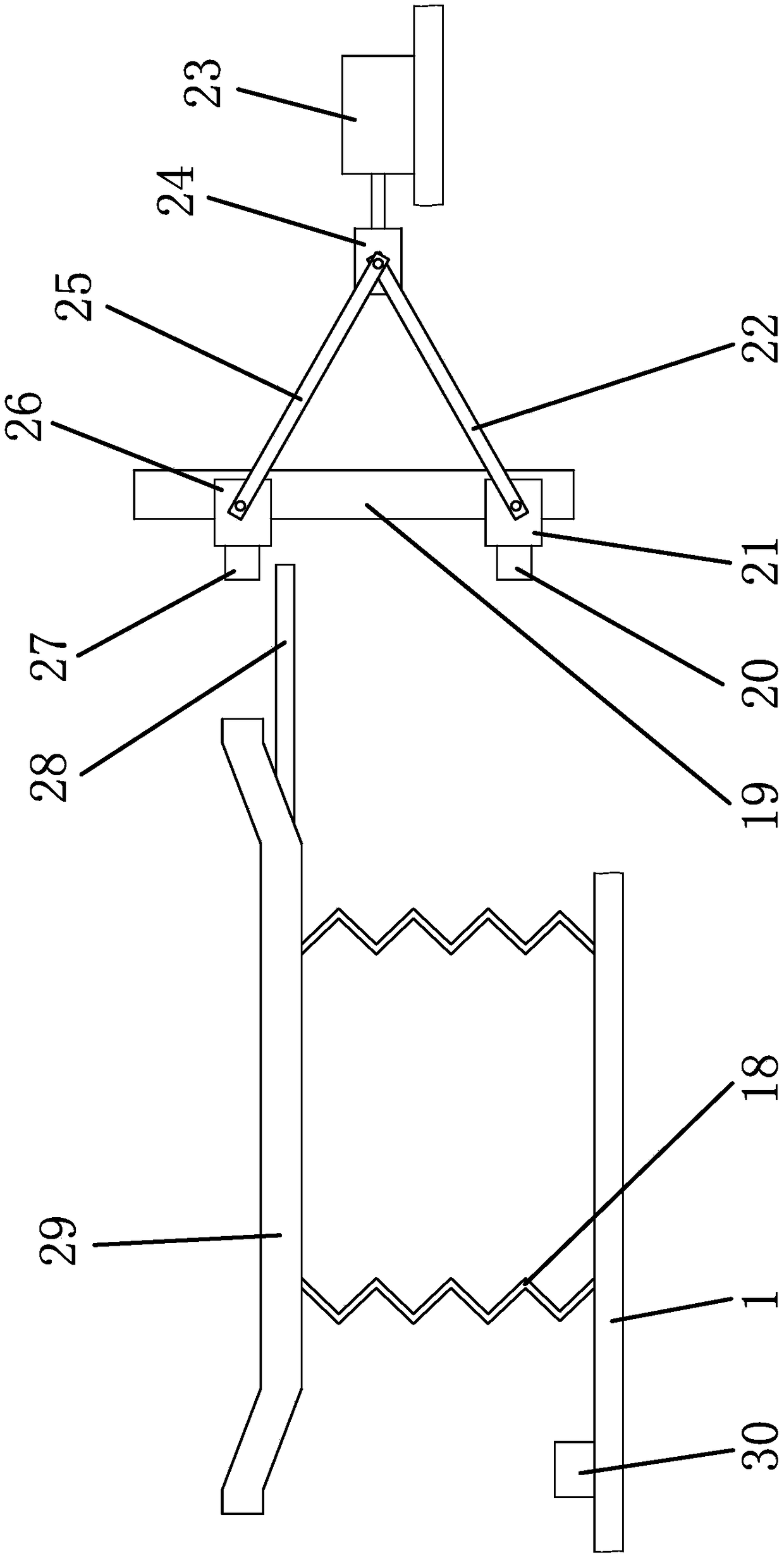

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0048] The improved multi-color reflective printing and dyeing method, the specific steps are as follows:

[0049] a. Purchase existing cotton-polyester composite fabrics on the market, and clean the fabrics with a vacuum cleaner;

[0050] b. Weigh 6-18 parts of reactive dyes, 10-20 parts of starch, 3-10 parts of urea, 2-12 parts of emulsified paste and 20-40 parts of water and put them into a beater for beating to obtain printing paste; In this example, 9 parts of reactive dyes, 13 parts of starch, 7 parts of urea, 6 parts of emulsified paste and 28 parts of water were weighed and put into a beater for beating to obtain printing paste; Existing materials available online;

[0051] c. Print the printing paste onto the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com