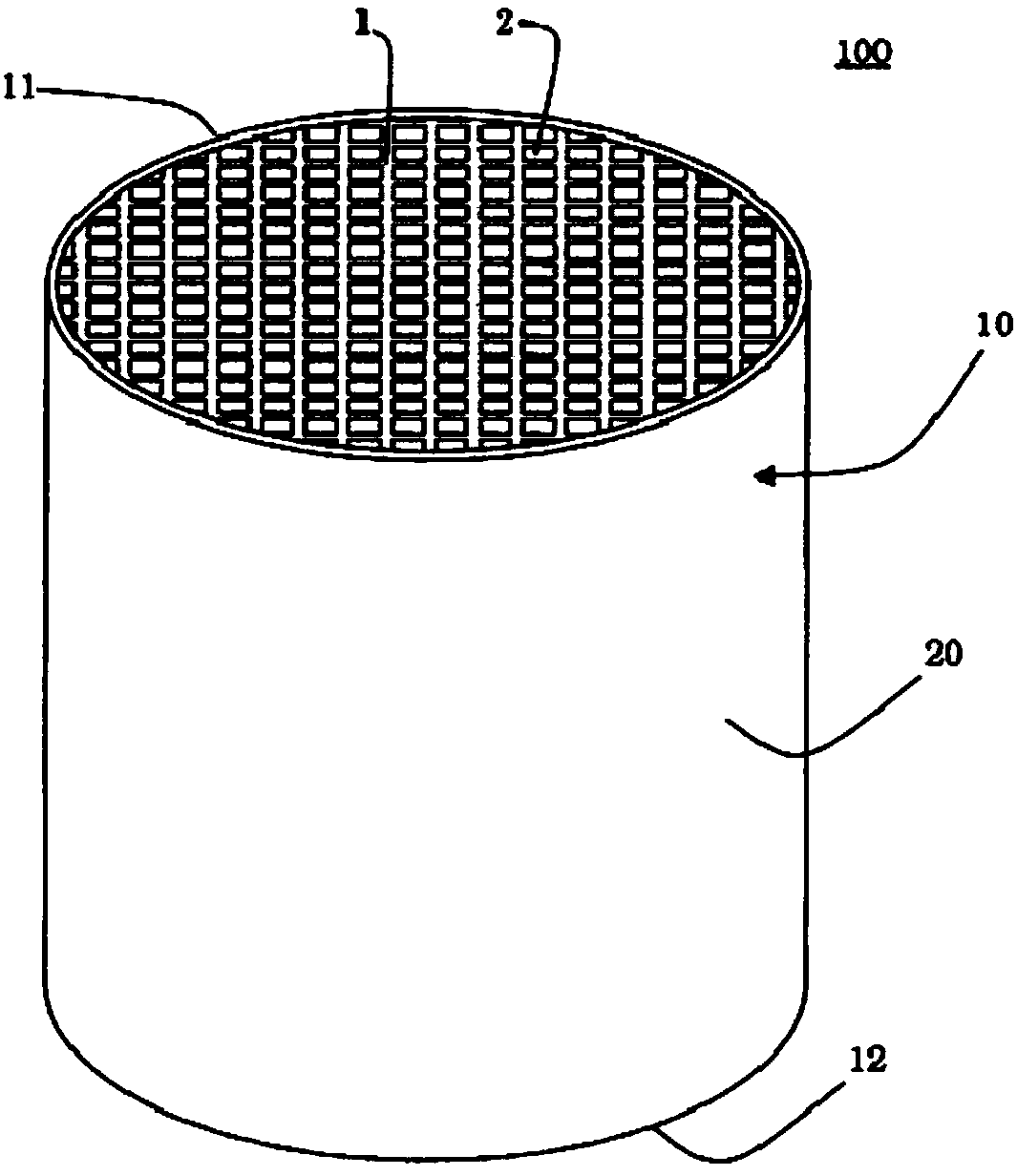

Honeycomb structure

一种蜂窝结构体、蜂窝结构的技术,应用在催化剂载体、家里用具、发动机元件等方向,能够解决劣化、无法抑制流量净化性能、废气流易发生停滞等问题,达到净化性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

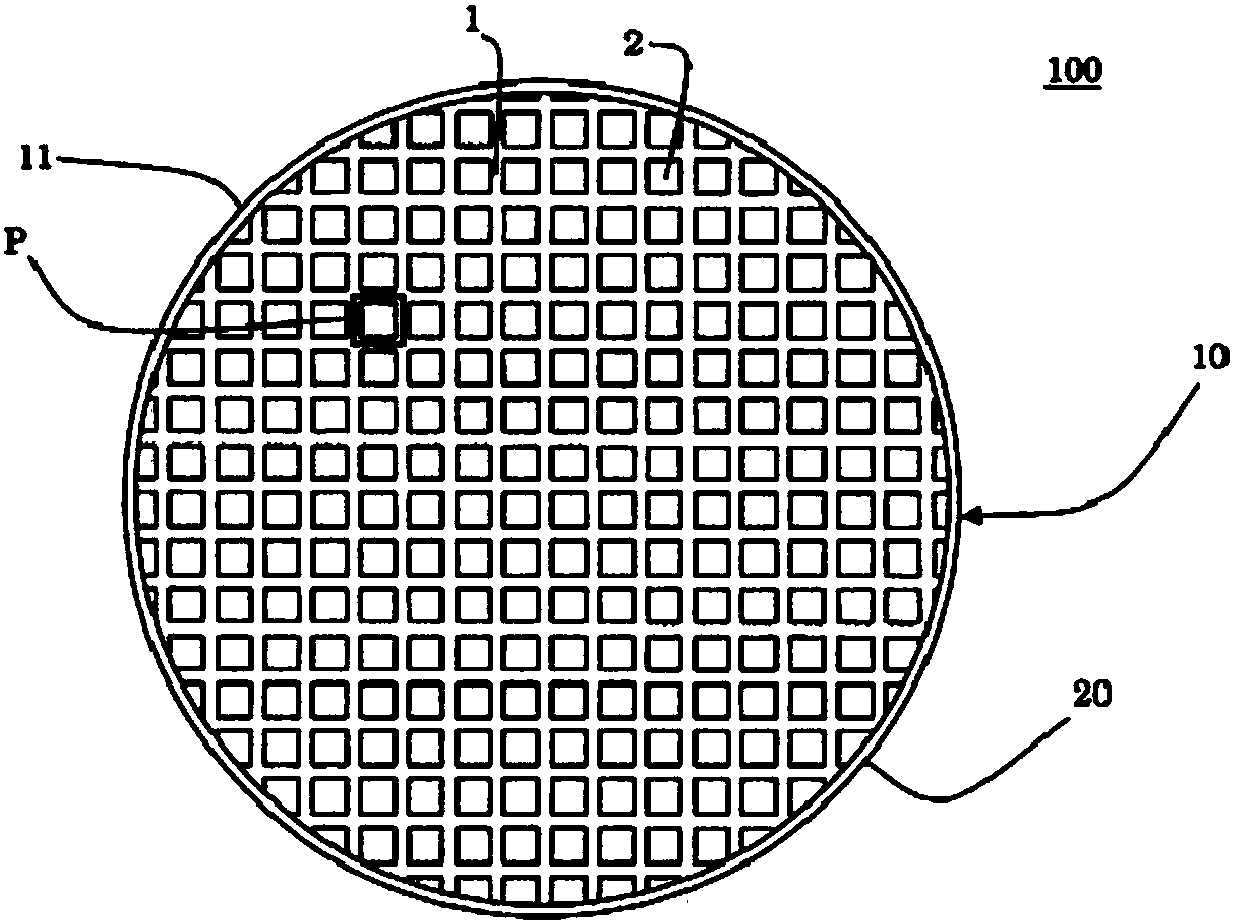

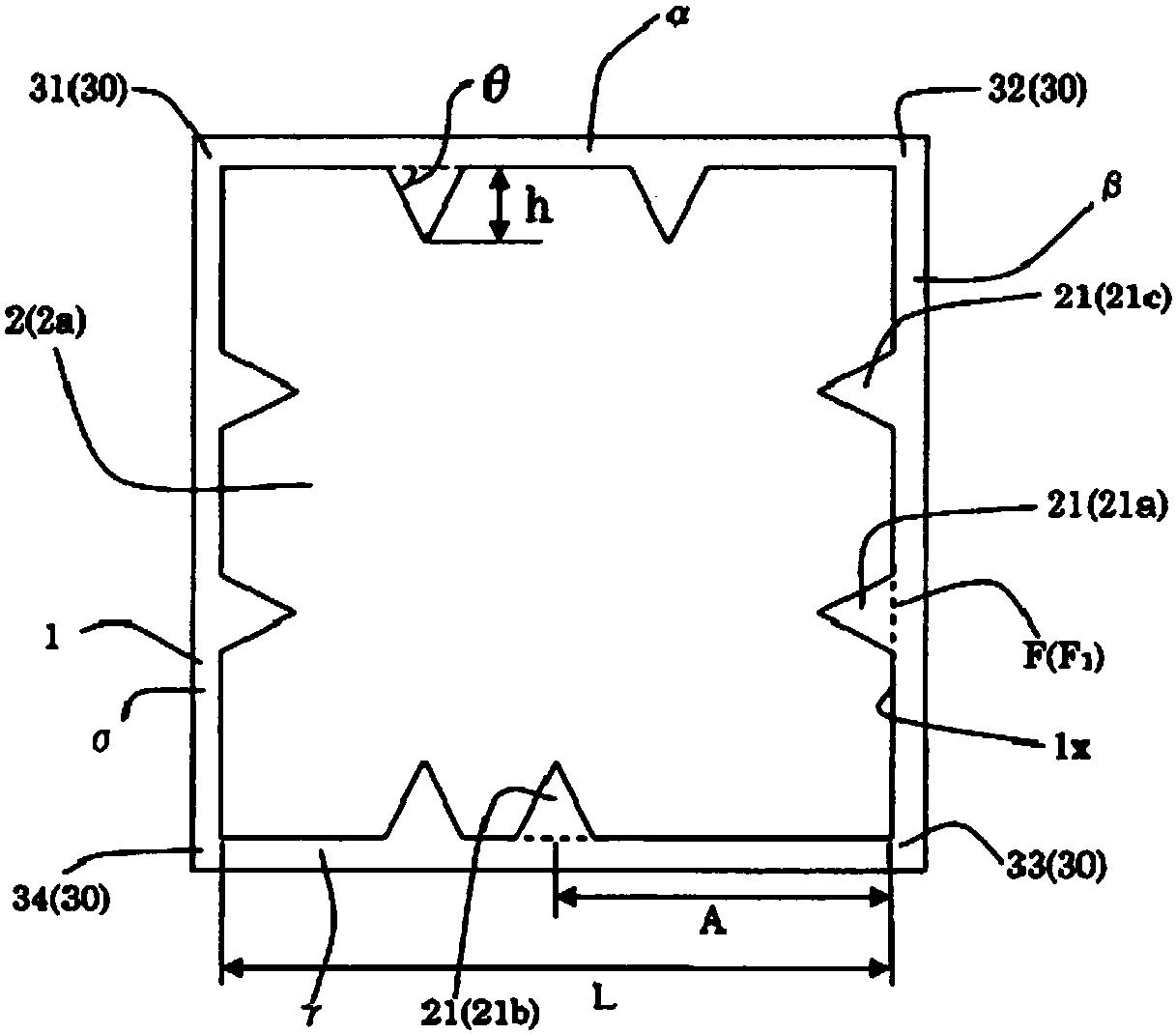

[0095] In Example 1, first, a molding material for producing a honeycomb structure was prepared. Specifically, a binder, a surfactant, a pore-forming material, and water are added to a ceramic raw material to form a molding raw material. It should be noted that kaolin, talc, and alumina, which are cordierite-forming raw materials, were used as ceramic raw materials.

[0096] Next, the obtained molding raw materials are kneaded with a kneader, and then kneaded with a vacuum mud mill to form a green body. Next, the obtained green body is extruded using a nozzle to produce a honeycomb molded body. As the nozzle, a nozzle for forming a honeycomb formed body having unevenly provided protrusions (that is, uneven corners) was used. After the honeycomb molded body is fired, the thickness of the partition wall is 0.089mm, and the cell density is 62 cells / cm 2 . The shape of the cells of the formed honeycomb body (the shape of the cells in a cross section perpendicular to the direct...

Embodiment 2~14、 comparative example 1、2

[0135] A honeycomb structure was produced in the same manner as in Example 1 except that the protrusions were arranged as shown in Table 1 and Table 2.

[0136] For the honeycomb structures of Examples 2 to 14 and Comparative Examples 1 and 2, the thickness of the partition wall (mm), the porosity (%) of the partition wall, and the cell density (cells / cm2) were measured in the same manner as in Example 1. 2 ), carry out LA-4 test and pressure loss measurement. The results are shown in Tables 1 to 3.

[0137] (result)

[0138] As shown in Table 3, it can be seen that the honeycomb structures of Examples 1 to 14 have uneven arrangement of protrusions, and thus, compared with the honeycomb structures of Comparative Examples 1 and 2, the exhaust gas purification performance after catalyst loading higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com