Water-based anticorrosive wax composition

A technology of composition and anti-corrosion wax, which is applied in anti-corrosion coatings, wax coatings, coatings, etc., can solve the problems that water-based anti-corrosion wax needs to be improved, and achieve the effect of solving corrosion problems, enhancing anti-corrosion performance, and reducing the amount of VOCs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

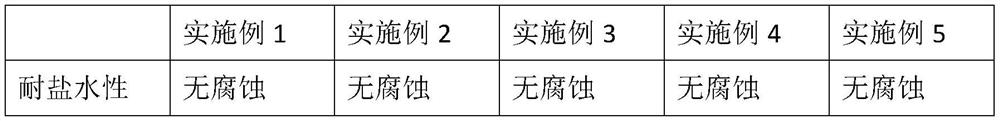

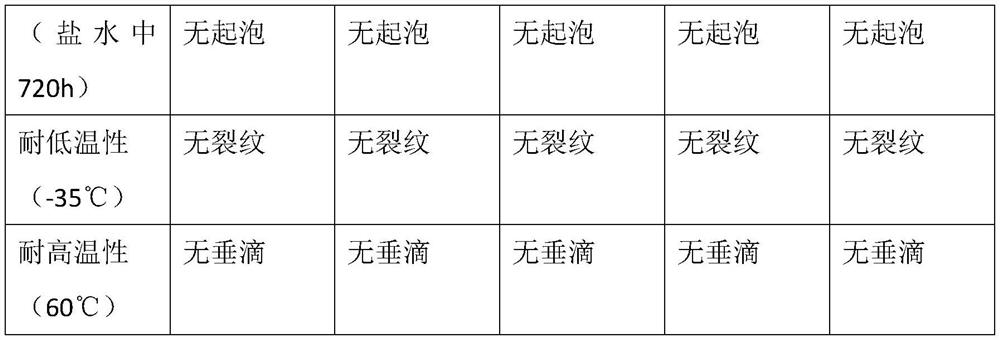

Examples

Embodiment 1

[0031] The preparation method of the water-based anti-corrosion wax composition described in this embodiment is:

[0032] Step 1. Add 38 parts of paraffin wax, 38 parts of polyisobutylene, 38 parts of polyethylene wax, and 19 parts of microcrystalline wax to the reaction system, heat to 100±5°C, and stir evenly; the paraffin wax, polyisobutylene , polyethylene wax, and the mass ratio of microcrystalline wax is 2:2:2:1.

[0033] Step 2: Add 11 parts of organic solvent and 1 part of rust inhibitor to the mixture of step 1, stir at a high speed, and stir evenly; the high-speed stirring is set to: rotating speed: 1800~2000r / min; temperature 40± 5 ℃; the antirust auxiliary agent is zinc powder; the organic solvent is polyethylene glycol;

[0034] Step 3. Add 10 parts of water-based epoxy resin, 2 parts of asphalt, and 3 parts of antioxidant to the uniform material of step 2, and the antioxidant is triethyl citrate; increase the temperature to 60±5℃ , and stir until the material i...

Embodiment 2

[0036] The preparation method of the water-based anti-corrosion wax composition described in this embodiment is:

[0037] Step 1. Add 40 parts of paraffin wax, 40 parts of polyisobutylene, 40 parts of polyethylene wax, and 20 parts of microcrystalline wax into the reaction system, heat to 100±5°C, and stir evenly; the paraffin wax, polyisobutylene , polyethylene wax, and the mass ratio of microcrystalline wax is 2:2:2:1.

[0038] Step 2: Add 12 parts of organic solvent and 2 parts of rust inhibitor to the mixture of step 1, stir at a high speed, and stir evenly; the high-speed stirring is set as: rotating speed: 1800~2000r / min; temperature 40± 5 ℃; the antirust auxiliary agent is zinc powder; the organic solvent is polyethylene glycol;

[0039] Step 3. Add 10 parts of water-based epoxy resin, 2 parts of asphalt, and 3 parts of antioxidant to the uniform material of step 2, and the antioxidant is triethyl citrate; increase the temperature to 60±5℃ , and stir until the materia...

Embodiment 3

[0041] The preparation method of the water-based anti-corrosion wax composition described in this embodiment is:

[0042] Step 1. Add 30 parts of paraffin wax, 30 parts of polyisobutylene, 30 parts of polyethylene wax and 15 parts of microcrystalline wax to the reaction system, heat to 100±5°C, and stir evenly; the paraffin wax, polyisobutylene , polyethylene wax, and the mass ratio of microcrystalline wax is 2:2:2:1.

[0043] Step 2: Add 10 parts of organic solvent and 1 part of rust inhibitor to the mixture of step 1, stir at high speed, and stir evenly; the high-speed stirring is set as: rotating speed: 1800~2000r / min; temperature 40± 5 ℃; the antirust auxiliary agent is zinc powder; the organic solvent is polyethylene glycol;

[0044] Step 3. Add 5 parts of water-based epoxy resin, 1 part of asphalt and 2 parts of antioxidant to the uniform material of step 2, and the antioxidant is triethyl citrate; increase the temperature to 60±5°C , and stir until the material is uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com