Efficient and safe drying equipment for building timber

A technology for drying equipment and wood, applied in the direction of wood drying, drying solid materials, drying room/container, etc., can solve the problems of great influence on quality, easy to cause deformation, long time consuming, etc., to increase the number of processing, avoid air pressure Dangerous, easy-to-ventilate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

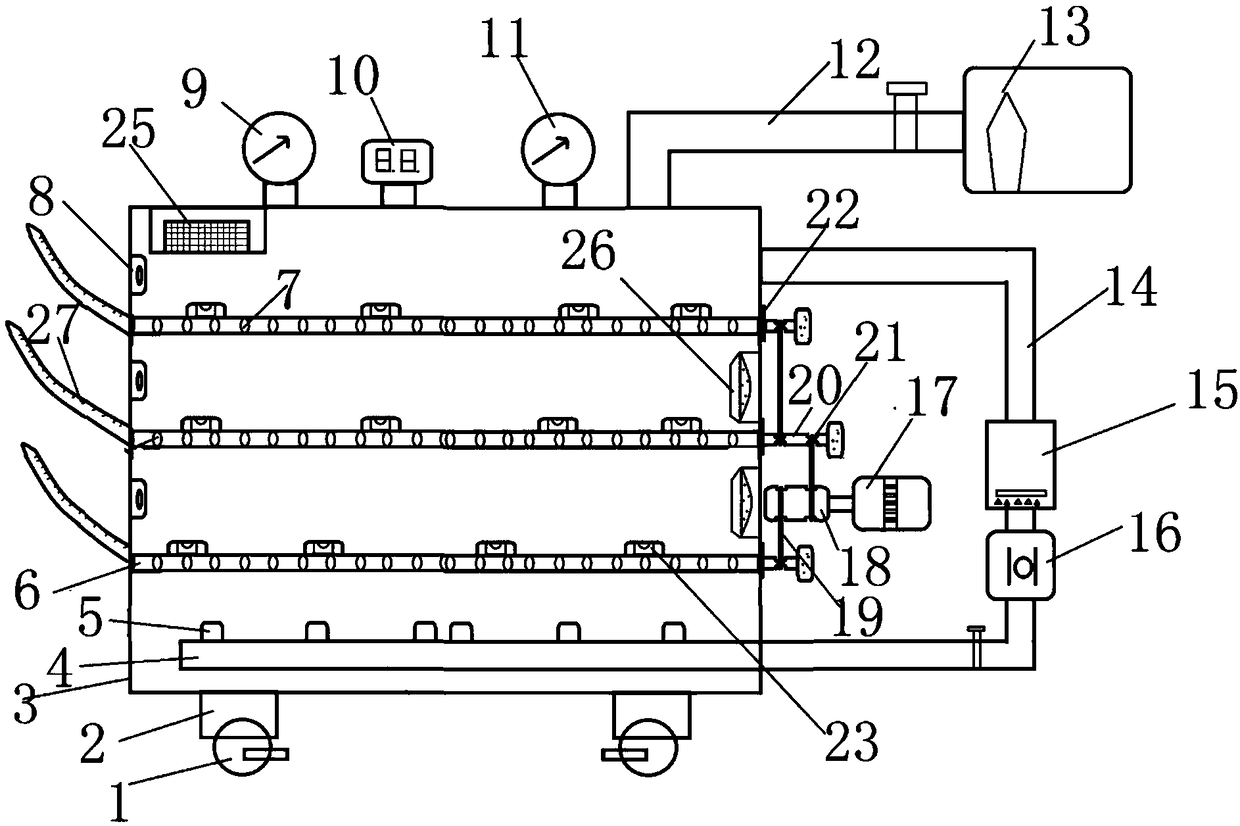

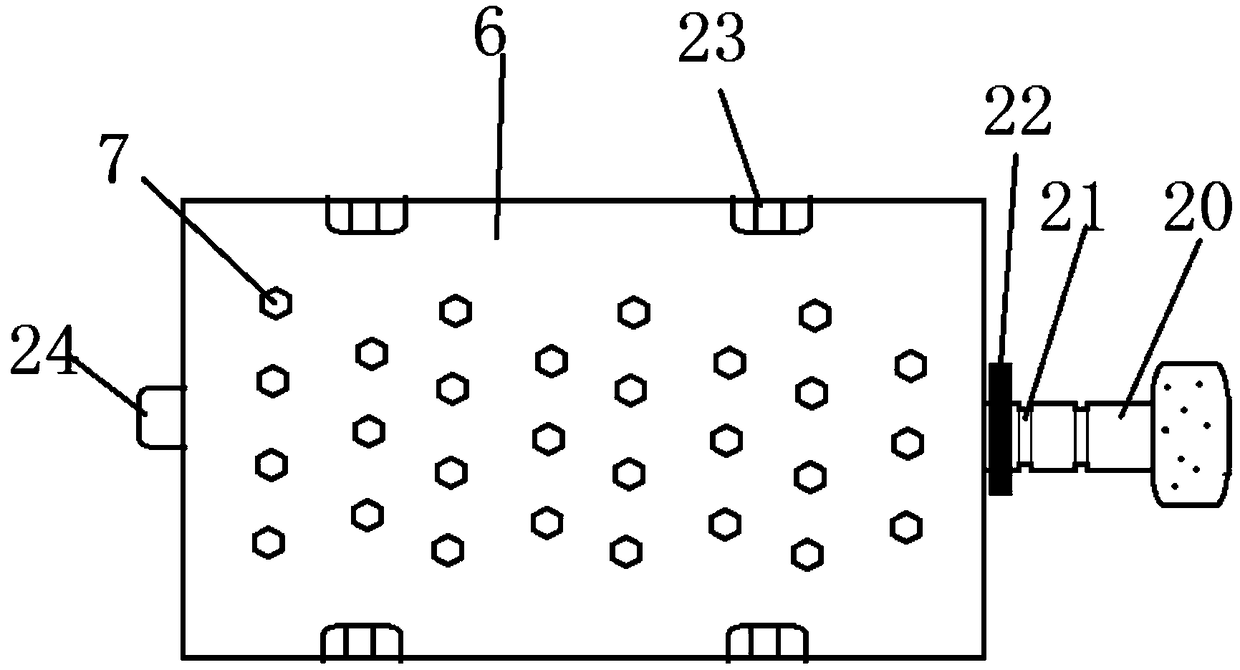

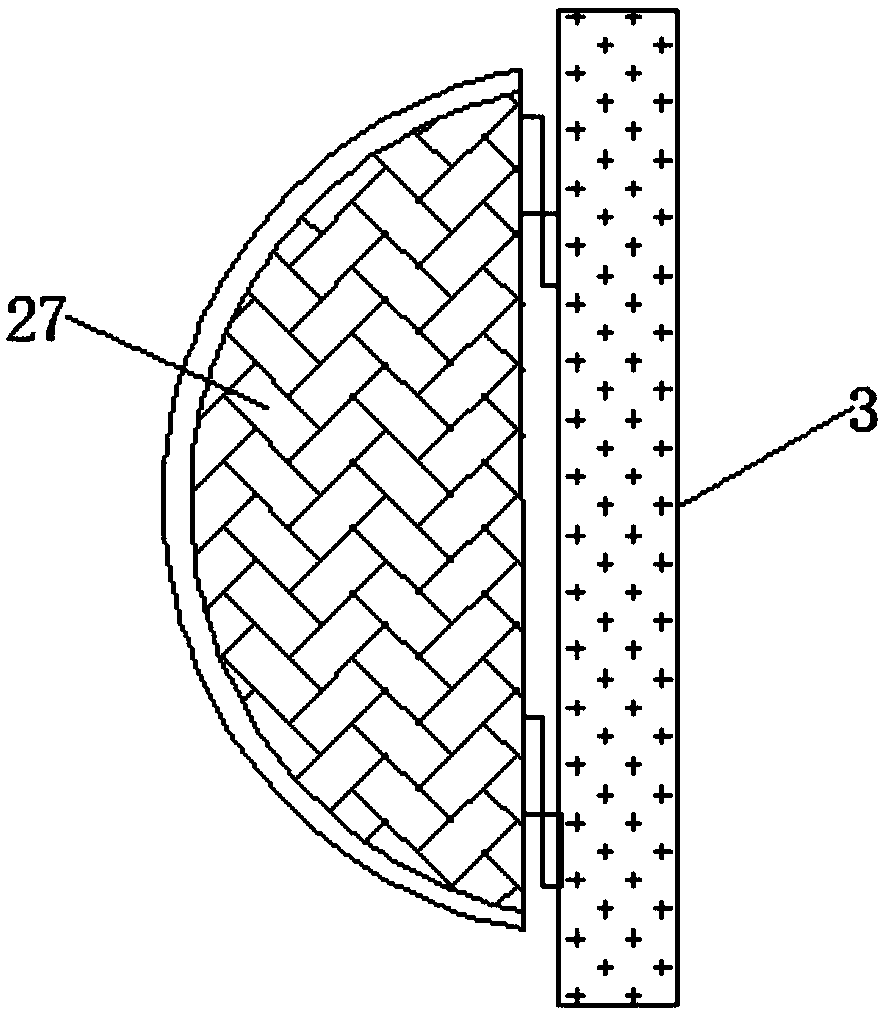

[0018] see Figure 1-3 , a high-efficiency and safe drying equipment for building wood, including a guide wheel 1, a drying box 3, a row pipe 4, a nozzle 5, a partition plate 6, a screen hole 7, a camera 8, an air guide pipe 12, a pressure reducing device 13, and an air return pipe 14 , steam heating box 15 and air pump 16, described drying box 3 bottoms are provided with supporting leg 2, and supporting leg 2 bottom ends are provided with guide wheel 1, and guide wheel 1 is provided with handbrake, and guide wheel 1 is convenient to move, and supporting leg 2 Prevent the overheating of the drying box 3 from causing damage to the ground and protect the ground. The drying box 3 is provided with a plurality of partitions 6, which are distributed equidistantly. Fixing clip 23 is provided on it, and the timber is clamped and fixed on the partition pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com