Unsaturated soil evaporating-dehumidifying direct shear apparatus and using method thereof

A direct shear instrument and dehumidification technology, which is applied in the field of unsaturated soil evaporative dehumidification direct shear instrument, can solve the problem that it is difficult to truly reflect the suction state of natural unsaturated soil, it is difficult to ensure the natural state of evaporative dehumidification, unsaturated soil Problems such as the determination of shear strength parameters, etc., to achieve the effect of short test period, simple structure and easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

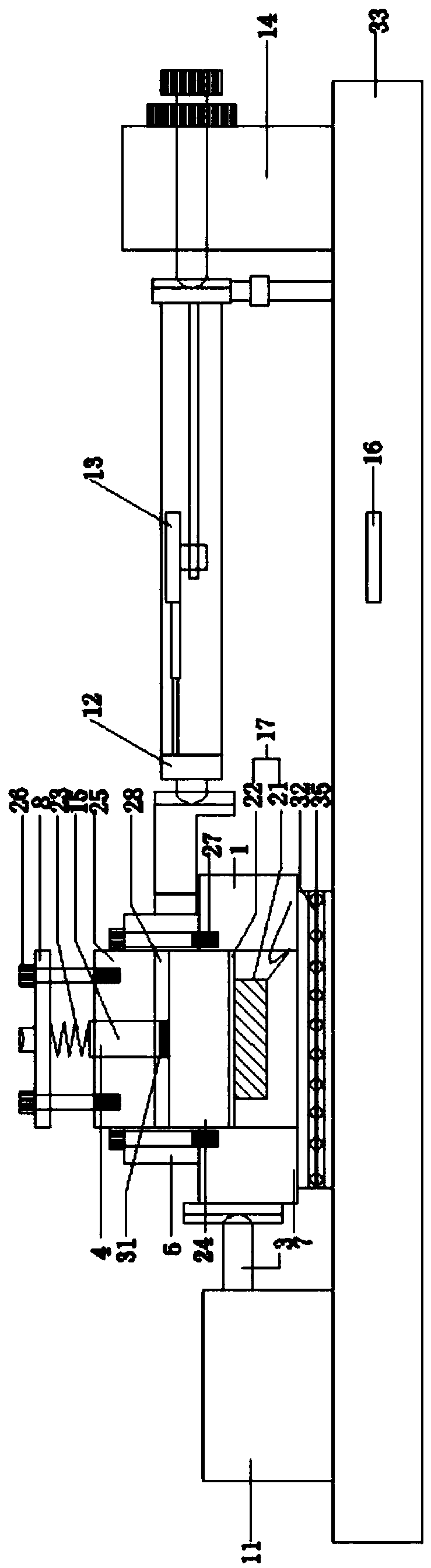

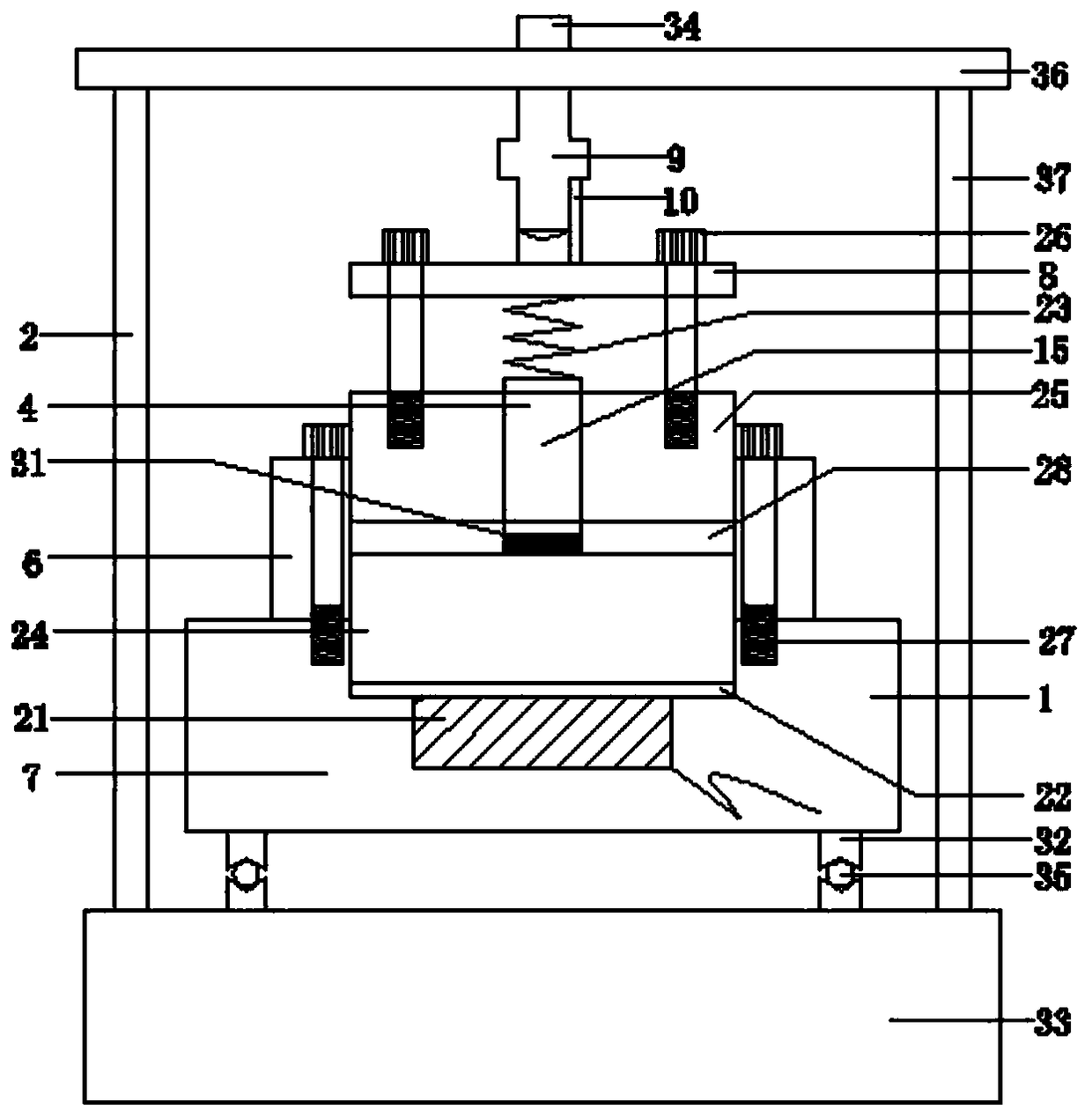

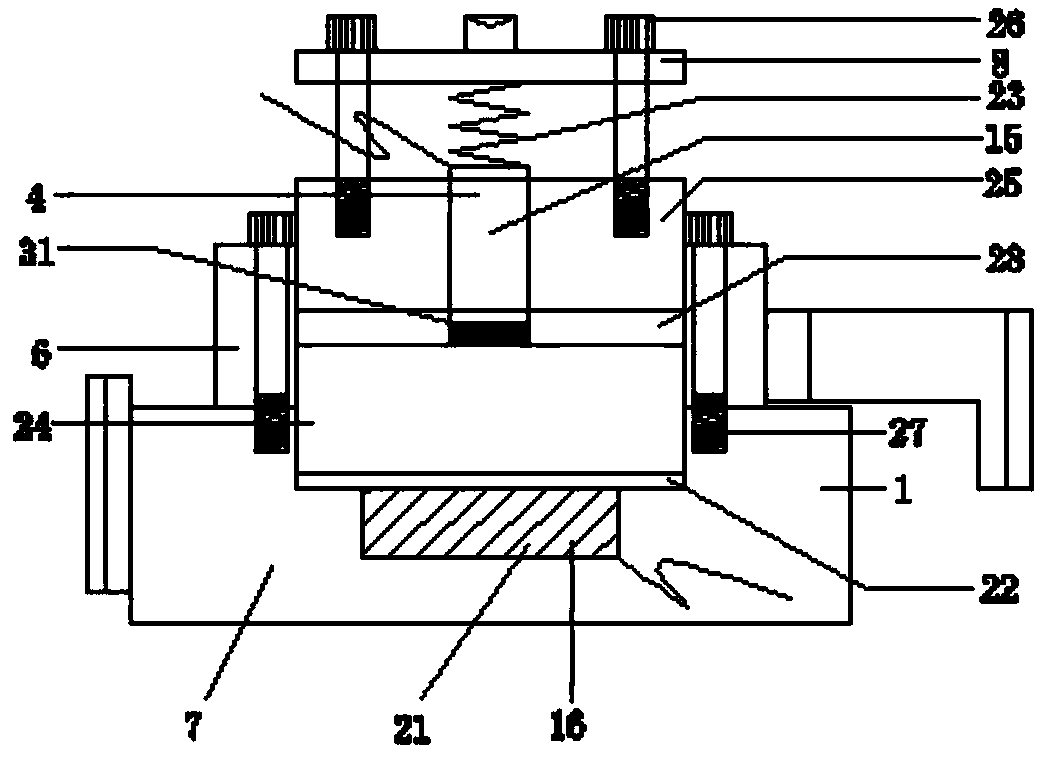

[0066] reference Figure 1-16 The present invention provides a method for using an unsaturated soil evaporative dehumidification direct shear apparatus, characterized in that the operation steps of the unsaturated soil evaporative dehumidification direct shear apparatus are:

[0067] Step 1: Put the heating resistor 21 and the heat-conducting metal plate 22 into the lower shear box 7 in sequence. The upper shear box 6 and the lower shear box 7 are stacked and aligned and then connected by pins 26. The thruster 11 of the horizontal loading device 3 is connected, and one side of the upper shear box 6 is connected with the end of the force ring 12 to provide horizontal loading for the shear box 1;

[0068] Step 2: Use a ring knife with the same size as the cavity interface of the shear box 1 to prepare the sample 24 to be tested;

[0069] Step 3: Place the sample 24 to be tested in the ring knife on the inner cavity of the upper shear box 6, and press the sample 24 to be tested into th...

Embodiment 2

[0076] reference Figure 1-16 The present invention provides a method for using an unsaturated soil evaporative dehumidification direct shear apparatus, characterized in that the operation steps of the unsaturated soil evaporative dehumidification direct shear apparatus are:

[0077] Step 1: Put the heating resistor 21 and the heat-conducting metal plate 22 into the lower shear box 7 in sequence. The upper shear box 6 and the lower shear box 7 are stacked and aligned and then connected by pins 26. The thruster 11 of the horizontal loading device 3 is connected, and one side of the upper shear box 6 is connected with the end of the force ring 12 to provide horizontal loading for the shear box 1;

[0078] Step 2: Use a ring knife with the same size as the cavity interface of the shear box 1 to prepare the sample 24 to be tested, and drill the sample hole to be tested in the center of the sample 24, the maximum drilling depth is 1 / 2 to be tested The height of the sample and the boreh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com