Clamping device for testing wheel hub motor, and testing method for clamping device

A technology of in-wheel motors and clamping devices, which is applied in the direction of motor generator testing, etc., can solve the problems that the fixtures cannot be applied to in-wheel motors of different specifications, the structure of the fixture is complicated, and the installation is inconvenient, so as to achieve fast testing, improve versatility, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

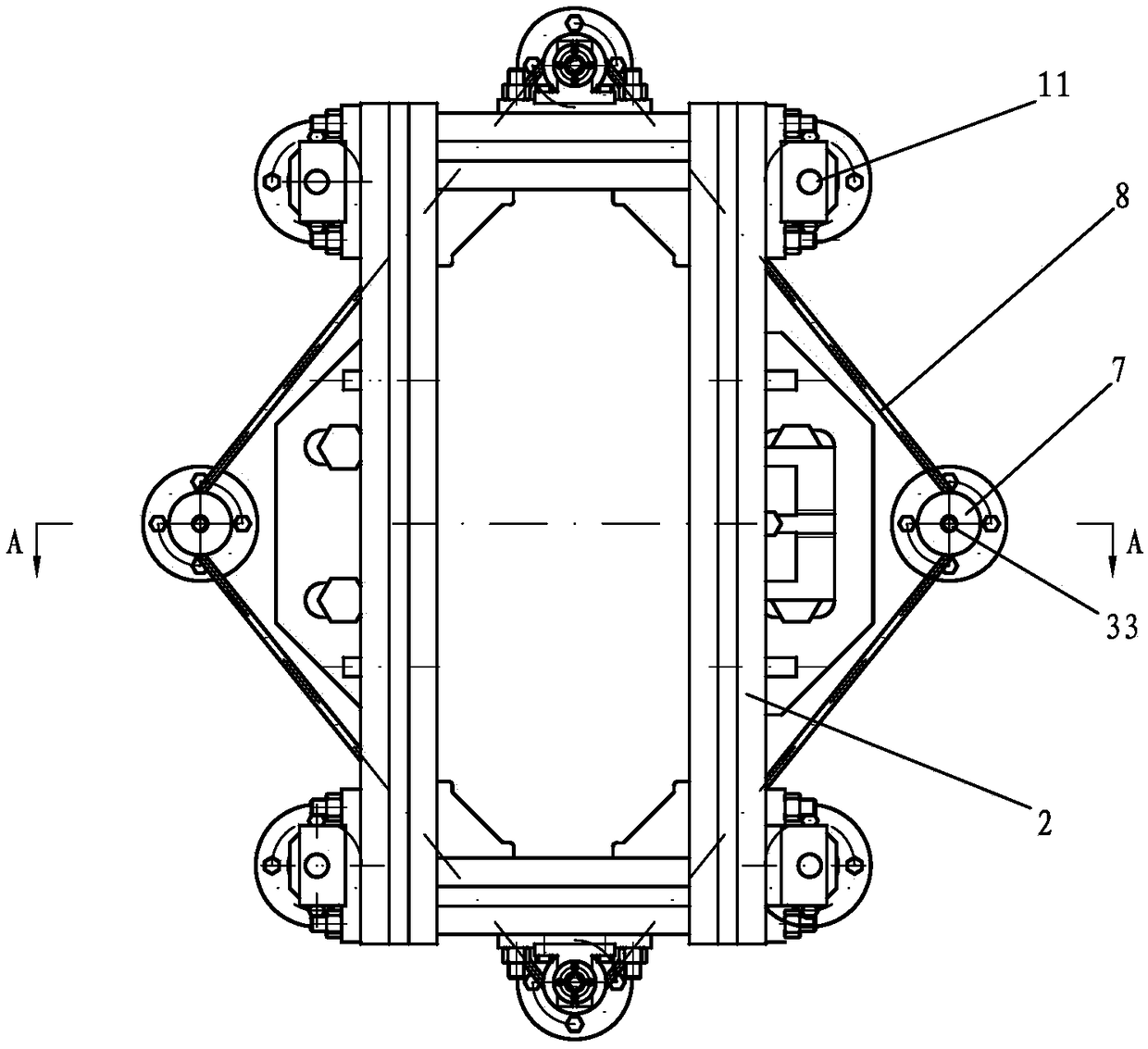

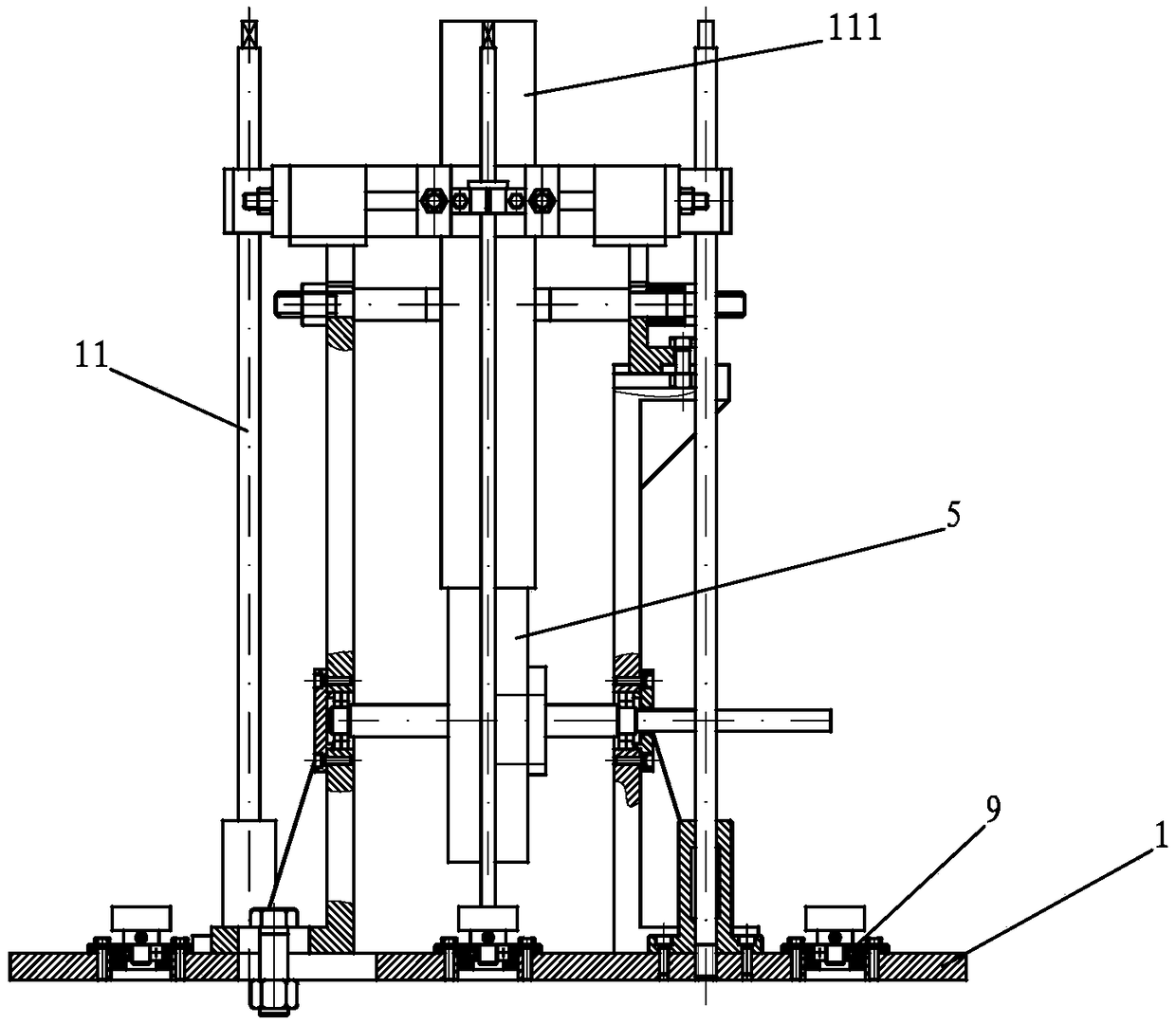

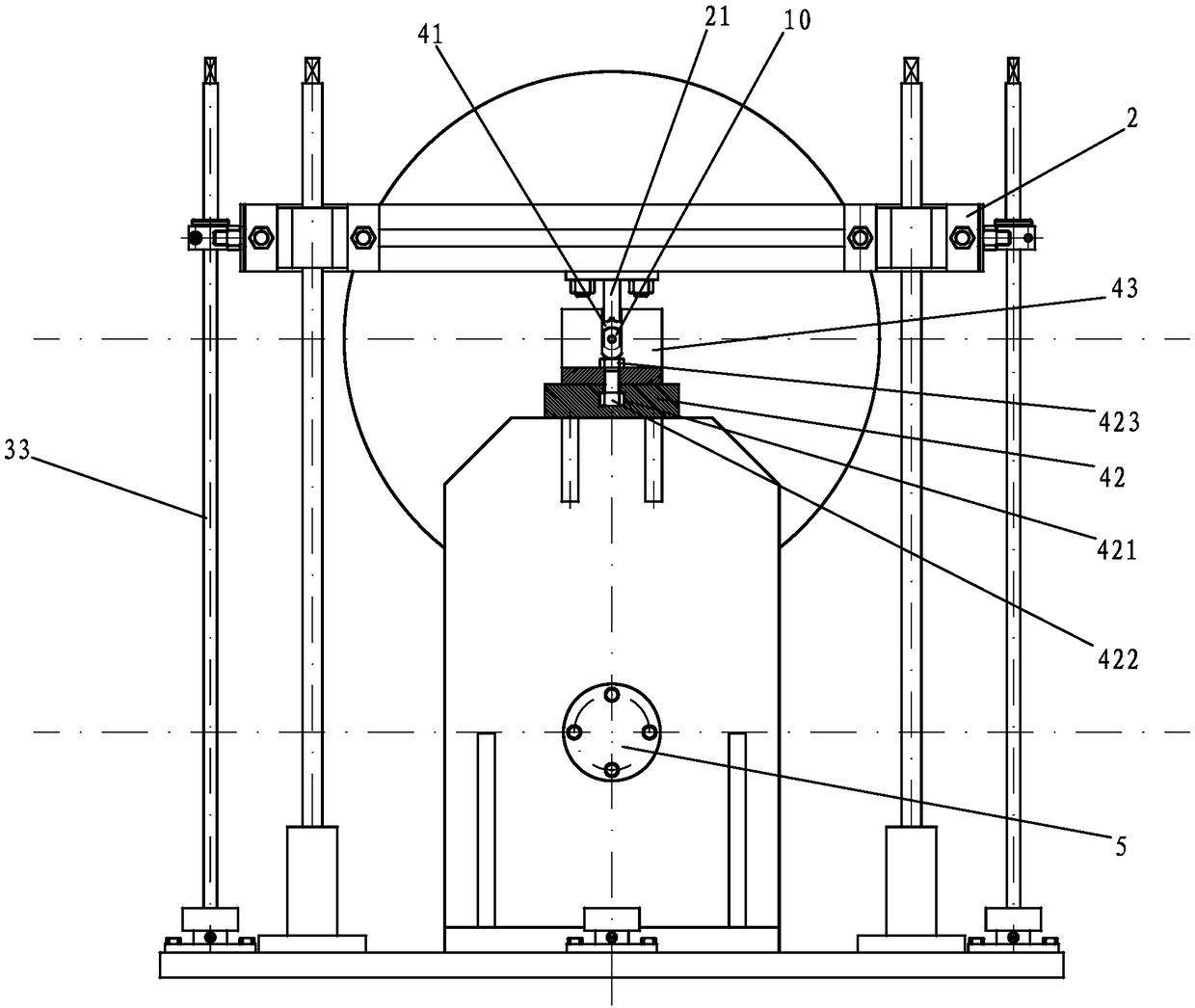

[0029] see Figure 1 to Figure 3 , the present embodiment relates to a test clamping device, including a base 1, a sliding frame 2, and a driving device 3. Several guide rods 11 are vertically installed on the base 1, and the sliding frame 2 is slidably sleeved on the guide rods. 11; a support 4 is installed on both sides of the base 1, and the support 4 is provided with a groove 41 for placing the hub motor shaft 10; the power output end of the driving device 3 is connected to the sliding The frame 2 is connected to drive the pressing device to slide on the guide rod 11, the friction wheel 5 is rotatably installed on the support 4, and the pressing block corresponding to the position of the groove 41 is fixedly installed on the sliding frame 2 21. When the driving device 3 drives the sliding frame 2 to slide downward, the pressing block 21 is inserted into the groove 41 to press the in-wheel motor shaft 10 rotatably in the groove 41, and the outer circle of the in-wheel motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com