High-temperature-resistant panel for high-voltage power distribution cabinet

A high-voltage power distribution and high-temperature-resistant technology, which is applied in the substation/power distribution device shell, anti-seismic equipment, etc., can solve the problems of non-fireproof performance, low cost of iron panels, and affecting normal work, etc., to achieve light weight and appearance Graceful, fire-stopping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

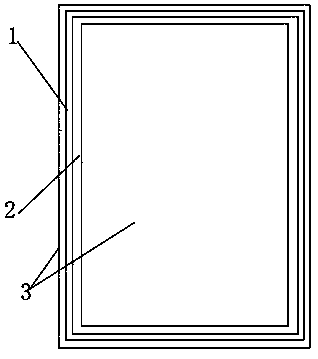

[0013] Such as figure 1 As shown, a high-temperature and high-pressure resistant power distribution cabinet panel according to the present invention includes an aluminum alloy substrate 1, an aluminum alloy substrate, and a rock wool insulation layer 2 glued on the inner side of the aluminum alloy substrate 1 through engineering glue, and the aluminum alloy substrate is more insulated than rock wool. The edge width of the layer is 0.5mm-1mm; a fireproof decorative panel 3 is provided on the outer surface of the aluminum alloy substrate and the inner surface of the rock wool insulation layer.

[0014] The thickness of the aluminum alloy substrate 1 is 3-4cm; the thickness of the rock wool insulation layer 2 is 1-2cm, which is natural rock, so it has strong high temperature resistance. If it is used, it will form a fire barrier, which can effectively avoid the spread of fire, slow down the drastic temperature changes inside and outside the box, and also has light weight, very sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com