Laser fiber coupler with low-mode dispersion

A fiber optic coupler and low-mode technology, applied in the field of couplers, can solve problems such as increasing temperature difference and accelerating heat diffusion, and achieve the effect of increasing temperature difference, accelerating heat diffusion, and increasing diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

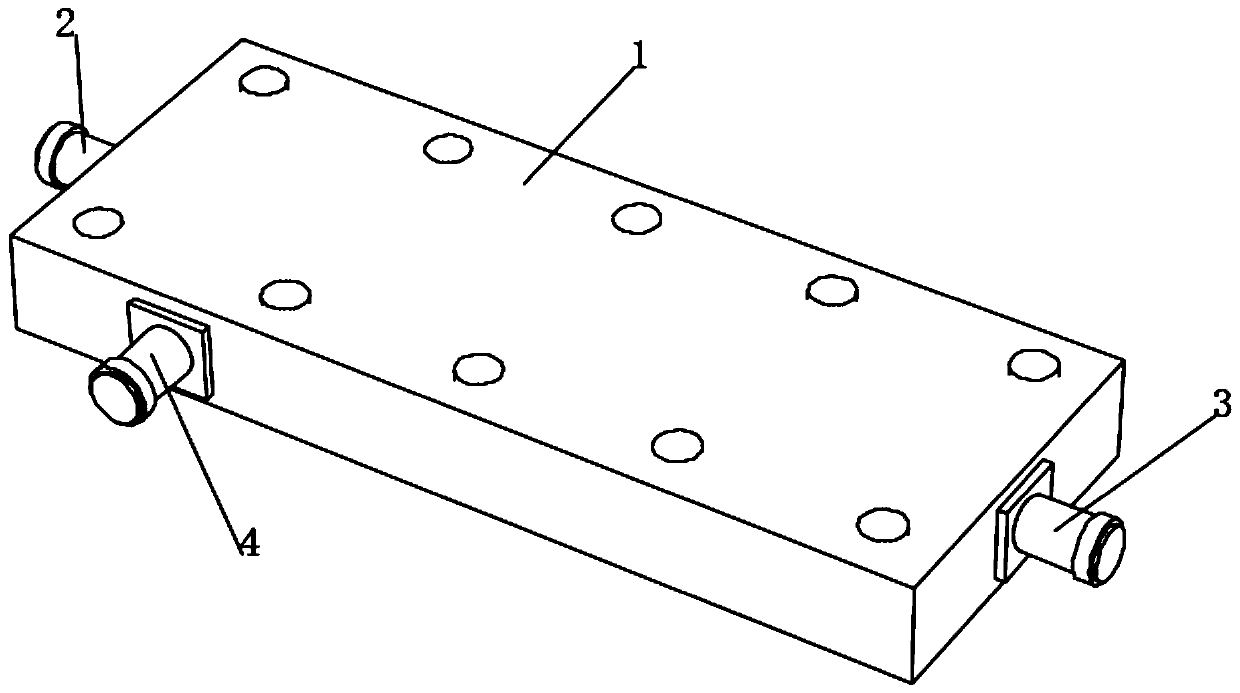

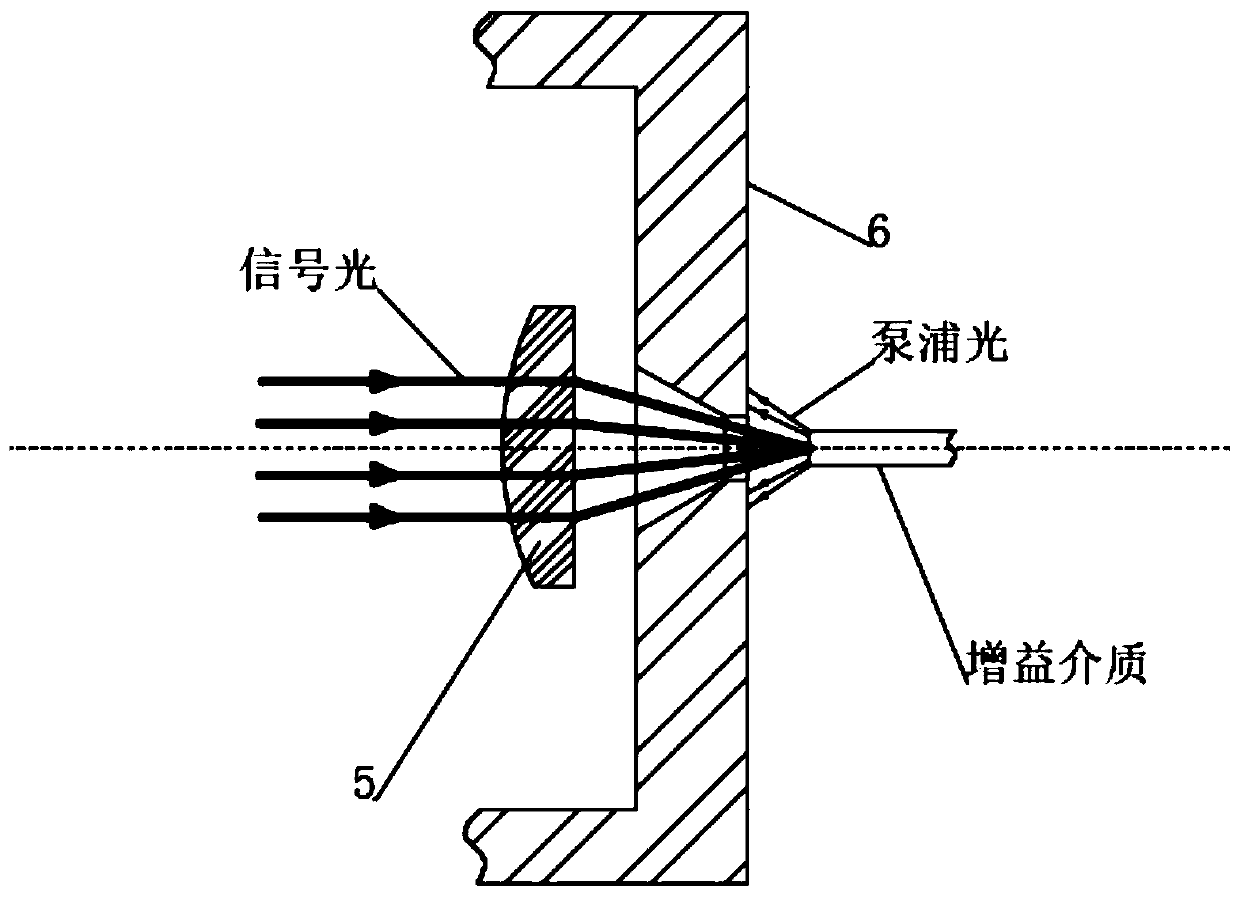

[0041] see Figure 1-2 , a low mode dispersion laser fiber coupler, comprising a coupler body 1, the left and right ends of the coupler body 1 are respectively connected to an input port 2 and an output port 3, the front end of the coupler body 1 is connected to a coupling port 4, the coupler body 1. A focusing mirror 5 is installed inside, and the outer cover of the focusing mirror 5 is provided with a diaphragm 6.

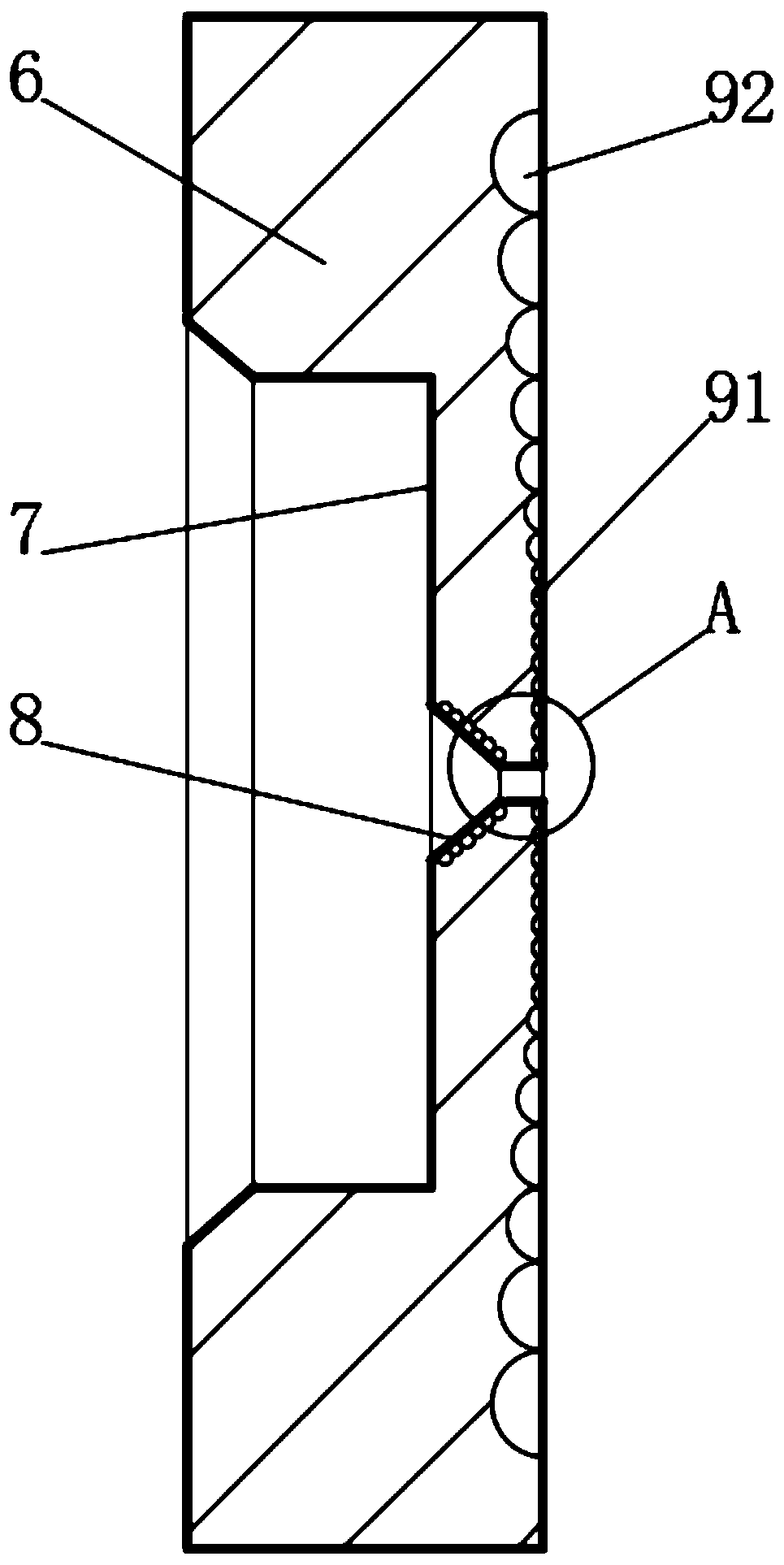

[0042] see image 3 , the end of the diaphragm 6 close to the focusing mirror 5 is dug with a cavity 7, the cavity 7 matches the focusing mirror 5, the inner wall of the cavity 7 and the focusing mirror 5 is dug with a diaphragm hole 8, and the coupler body 1 is also connected There is a gain medium, the gain medium is located on the right side of the diaphragm 6, the focusing mirror 5, the cavity 7, the diaphragm hole 8 and the gain medium are arranged in sequence from left to right, and the four are located on the same center line, and the diaphragm 6 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com