Method for regulating the regeneration time of an adsorption dryer and adsorption dryer implementing such a method

A technology of adsorption drying and regeneration time, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of unoptimized energy consumption, failure to consider the current state of the adsorption column, and inefficient methods to achieve energy consumption The effect of reducing, influencing, and eliminating the influence of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

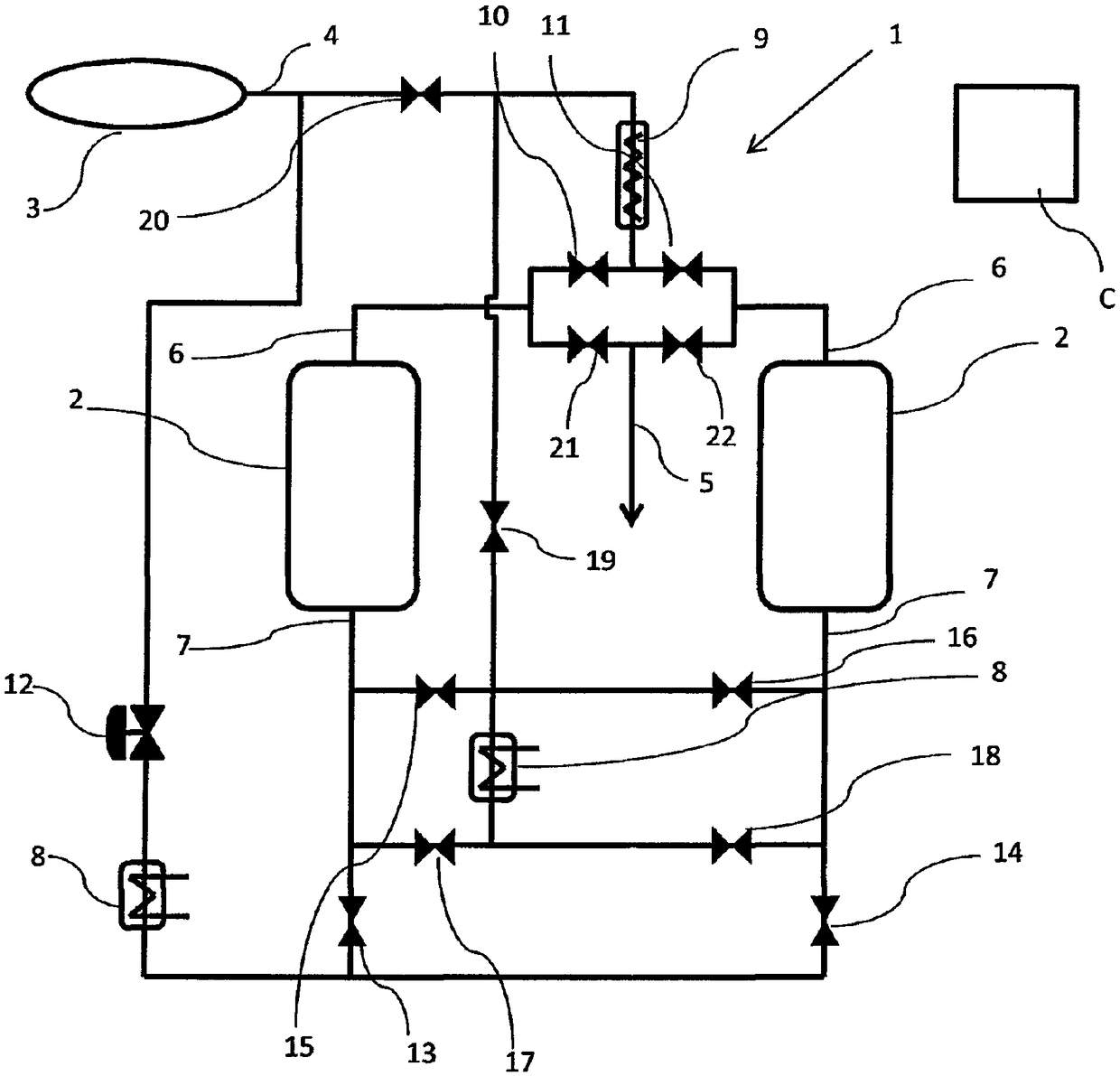

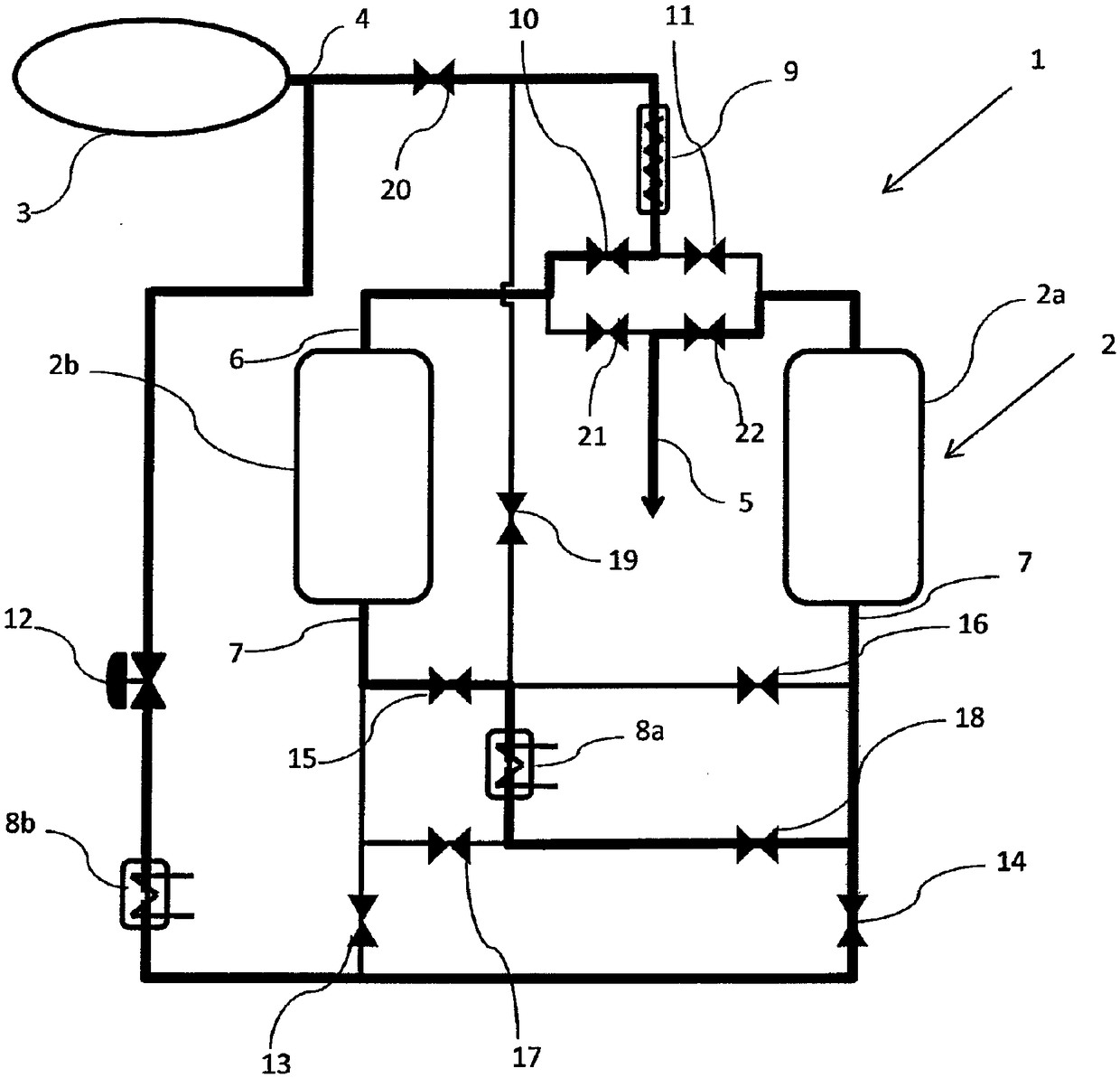

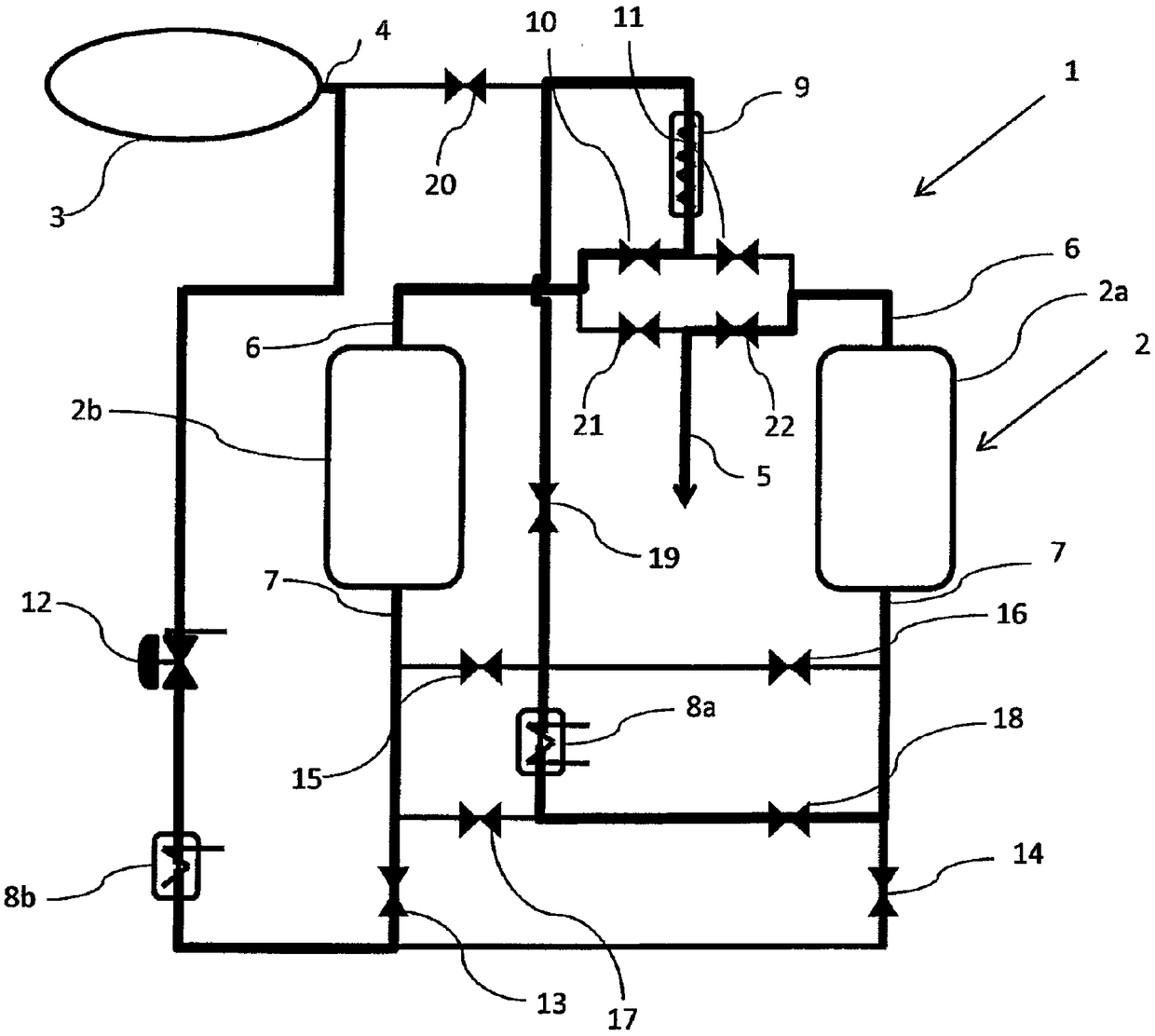

[0049] figure 1 An adsorption dryer 1 is shown, which in this case comprises two adsorption vessels 2 connected to a gas source 3 via a dryer inlet 4 . The adsorption dryer 1 is capable of removing moisture from the gas flowing through the dryer inlet 4 and provides dry and possibly cold gas via the dryer outlet 5 to an external network (not shown).

[0050] In the context of the present invention, it is understood that the adsorption dryer 1 may also comprise more than two adsorption vessels 2 or even only one adsorption vessel 2 .

[0051] Preferably, the adsorption vessel 2 comprises an adsorption material (not shown) capable of capturing moisture from the gas flowing therethrough.

[0052] In the context of the present invention, it is understood that adsorption may also include absorption.

[0053] Each of the two adsorption vessels 2 comprises an inlet 6 and an outlet 7 for allowing gas to flow therethrough. The adsorption dryer 1 also comprises a controller unit C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com