High-strength and high-corrosion-resistant ni-based alloy having excellent hot forgeability

A high-corrosion-resistant, high-strength technology, applied in the field of high-strength and high-corrosion-resistant Ni-based alloys with excellent hot forgeability, to achieve the effects of excellent yield strength, excellent effect, and excellent hot forgeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

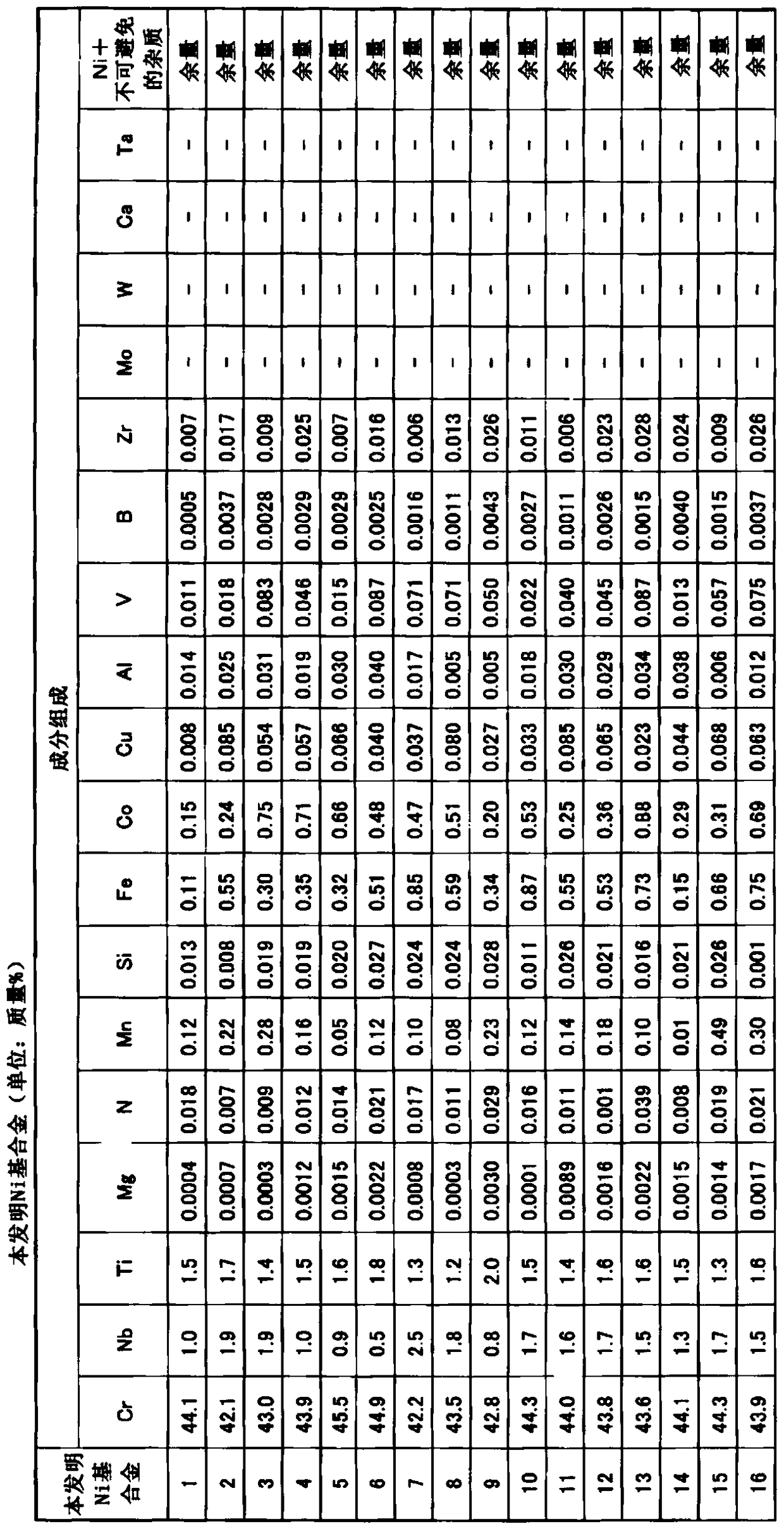

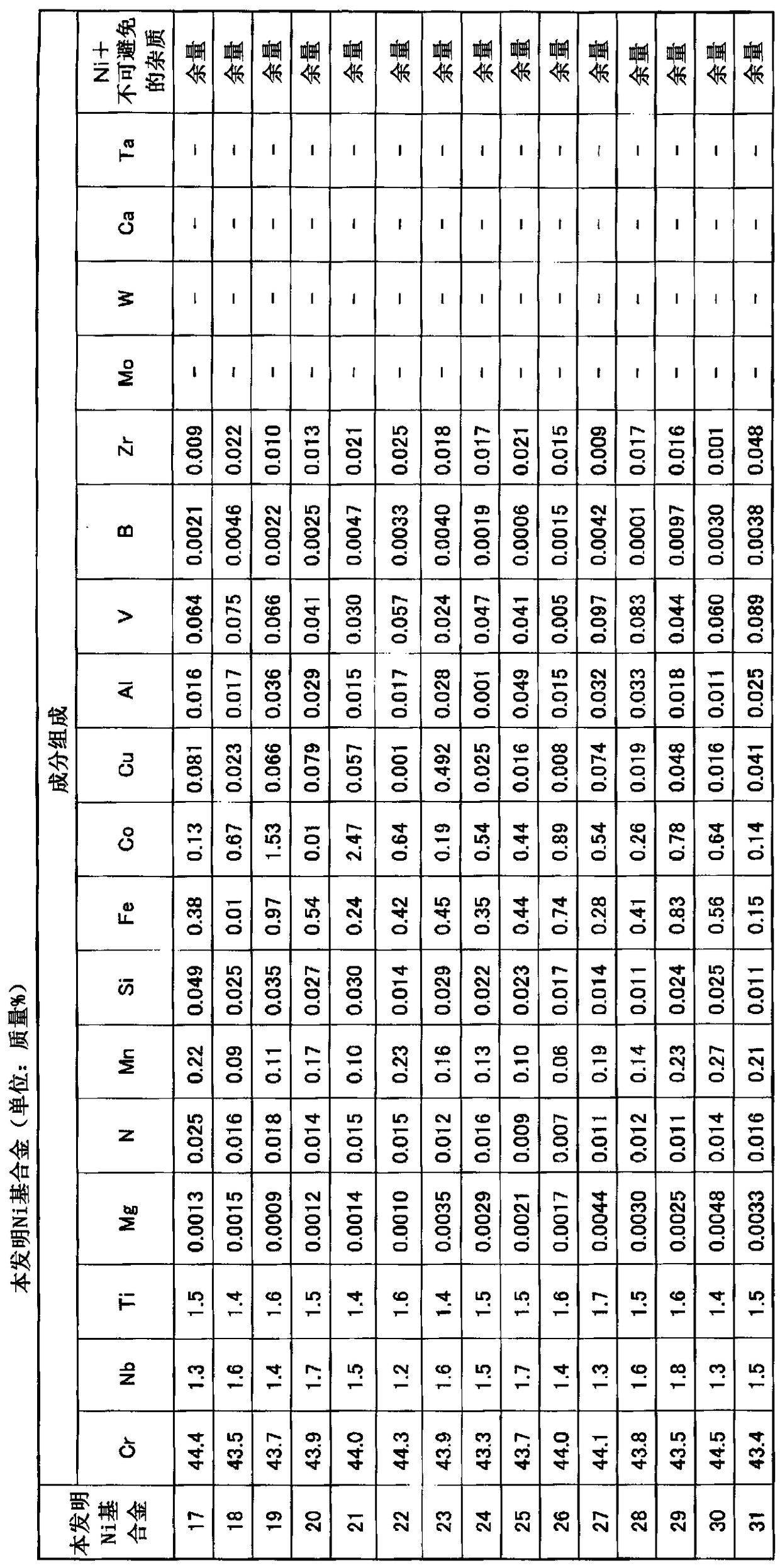

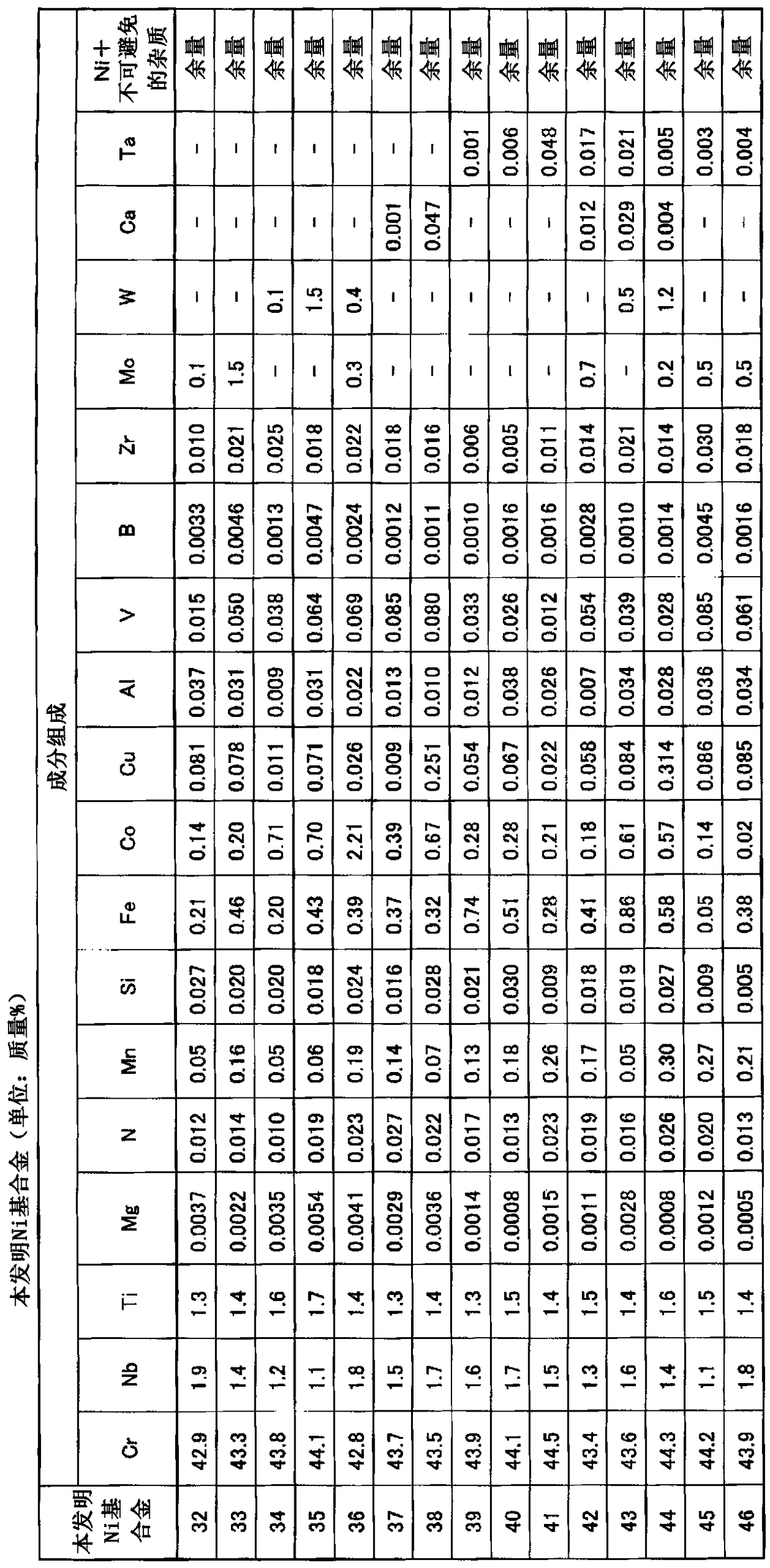

[0107] By adopting a conventional vacuum high-frequency melting furnace, melting a Ni-based alloy with a specified composition, and melting about 10 kg of a cylindrical ingot of 80mmφ×240mm, the smelted material of the Ni-based alloy is obtained. By performing homogenization heat treatment on the ingot at 1230° C. for 10 hours and water cooling, the Ni-based alloys 1 to 46 of the present invention shown in Tables 1 to 3 and the comparative Ni-based alloys 1 to 26 shown in Tables 4 and 5 were prepared. . In addition, for the forging trial production, there was a shrinkage cavity caused by casting at the end, so the shrinkage cavity portion (about 2 kg from the upper side) was removed. In addition, defects such as blemishes on the surface were removed by grinding with a grinder.

[0108] In addition, commercially available aging heat-treated product round bars were purchased and used as conventional Ni-based alloys 1 to 3 shown in Table 6. It should be noted that the conventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com