Sausage casing drying rack

A technology for drying racks and casings, which is applied in the fields of hanging meat/sausage, slaughtering, food science, etc. It can solve the problems of inconvenient operation and casing damage, and achieve the effects of convenient operation, optimized performance, and reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The casing drying rack is used for drying the casings, so that the casings can be dried quickly.

[0035] The casing drying rack includes a base 1 and a hanger 2 arranged on the base 1, the hanger 2 is arranged on the base 1 through a height adjustment mechanism 3, and the height adjustment mechanism 3 adjusts the hanger 2 relative to the horizontal plane. When the casing is fixed on the hanging frame 2, the hanging frame 2 can have a lower height to facilitate the operation of the operator. When the casing is dried, the hanging frame 2 can be made to have a higher height to save space. Since the height of the hanger 2 can be adjusted conveniently, the operation of the operator is facilitated and the labor intensity of the operator is reduced.

[0036] A water receiving pool 4 is arranged on the base 1, and the water receiving pool 4 can be placed on the base 1 without being fixed. The water receiving pool 4 is provided with a drain nozzle 5 for discharging waste wate...

Embodiment 2

[0040] This embodiment introduces the first form of the height adjustment mechanism 3 in combination with Embodiment 1.

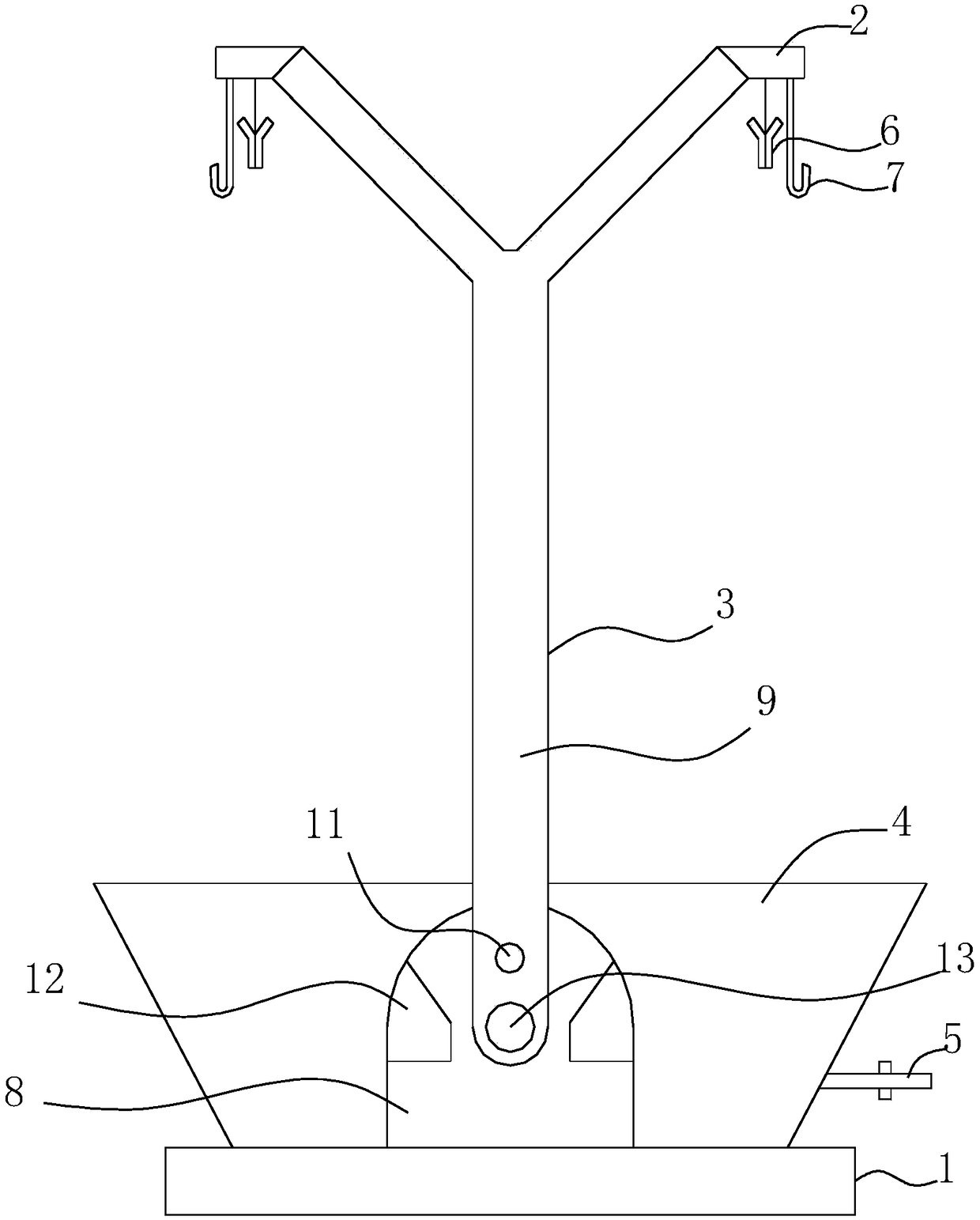

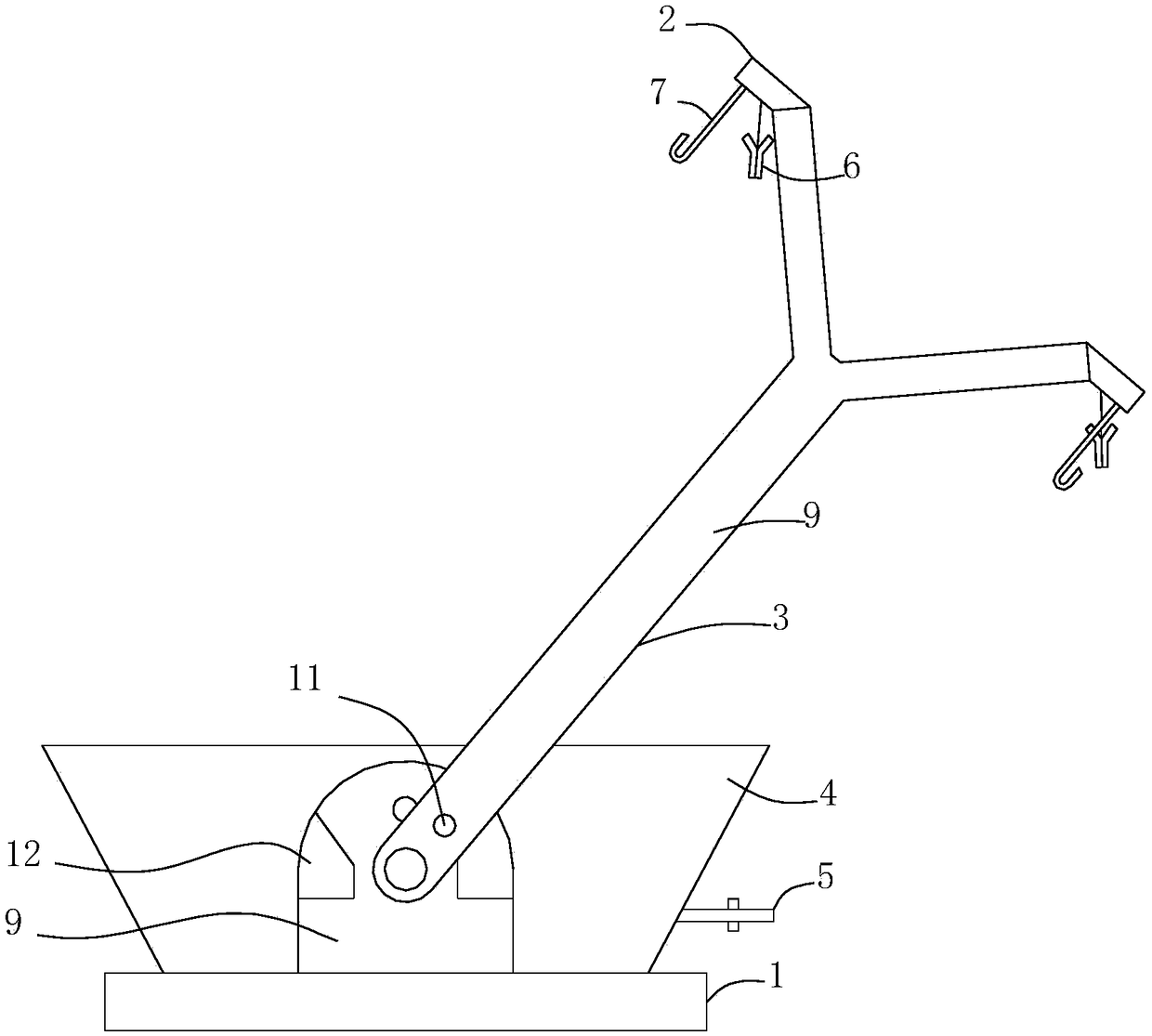

[0041] Such as figure 1 , figure 2 As shown, the height adjustment mechanism 3 includes a mounting plate 8 arranged on the base 1, the mounting plate 8 can be welded on the base 1, and a column 9 is rotatably connected to the mounting plate 8, and the column 9 passes through The rotating shaft 13 is rotatably connected to the mounting plate 8, the hanger 2 is fixed on the column 9, and the mounting plate 8 is provided with a positioning hole for positioning the column 9 in a vertical state. The column 9 is positioned in a vertical state by the pin shaft 11, and the pin shaft 11 is matched with the positioning hole, and a limit block 12 that limits the rotation angle of the column 9 is also provided on the mounting plate 8. The limit block 12 interferes with the column 9 to limit the rotation angle of the column 9, the limit block 12 can be integrated wit...

Embodiment 3

[0045] This embodiment introduces the second form of the height adjustment mechanism 3 in combination with the embodiment 1.

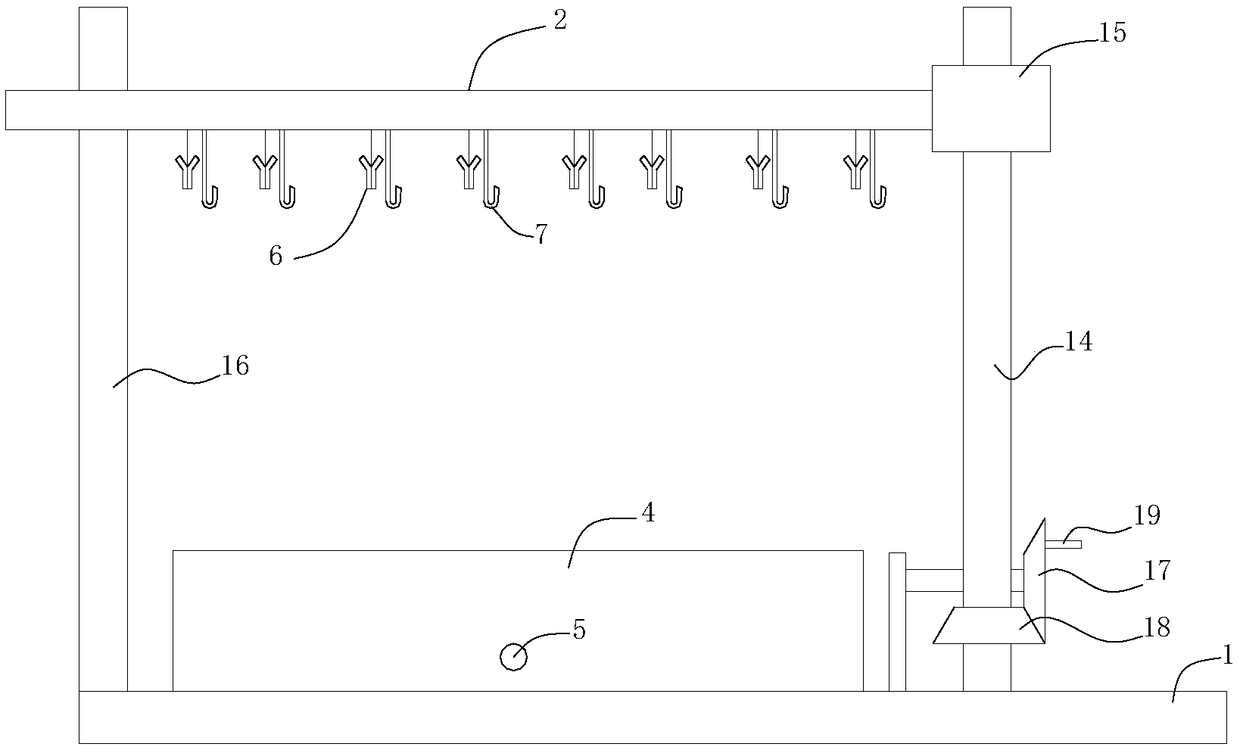

[0046] Such as image 3 As shown, the height adjustment mechanism 3 includes a lead screw 14 that is rotatably connected to the base 1. The lead screw 14 can be rotatably connected to the base 1 through a thrust bearing. The nut seat 15 that bar 14 cooperates, and described hanger 2 is fixed on the described nut seat 15, and hanger 2 can be fixed on the nut seat 15 by any kind of method, for example but not limited to hanger 2 is fixed on by screw On the nut seat 15.

[0047] The base 1 is also provided with a guide rail 16 guiding the hanger 2 , the guide rail 16 is parallel to the lead screw 14 , the guide rail 16 can be welded on the base 1 , and the guide rail 16 can also be integrated with the base 1 . The hanger 2 is sleeved on the guide rail 16 , and a driving mechanism for driving the screw 14 to rotate is arranged on the base 1 .

[0048] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com