Electric car utilizing rotation of hubs for electricity generation

A technology for electric vehicles and wheel hubs, applied in electric vehicles, electric vehicle charging technology, battery circuit devices, etc., can solve the problem of not easy long-lasting battery life, save energy and charging time, improve the level of environmental protection and energy saving, and achieve long battery life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

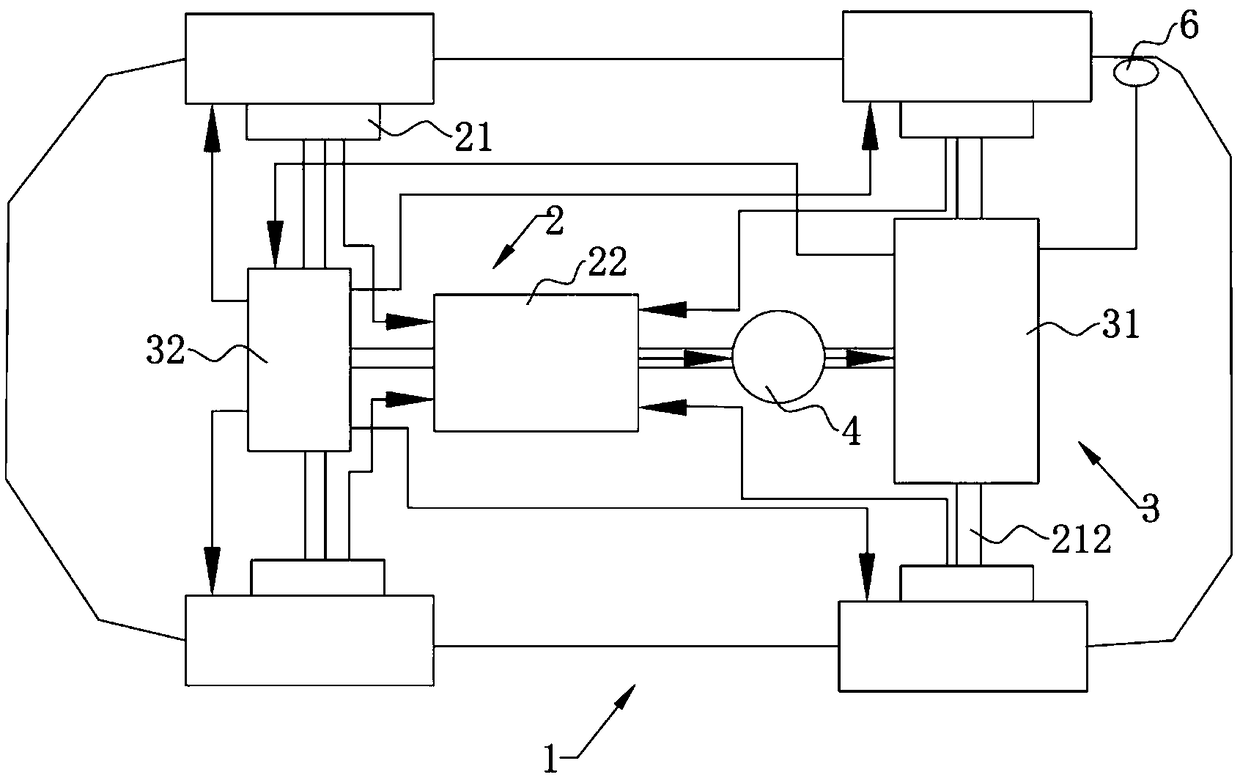

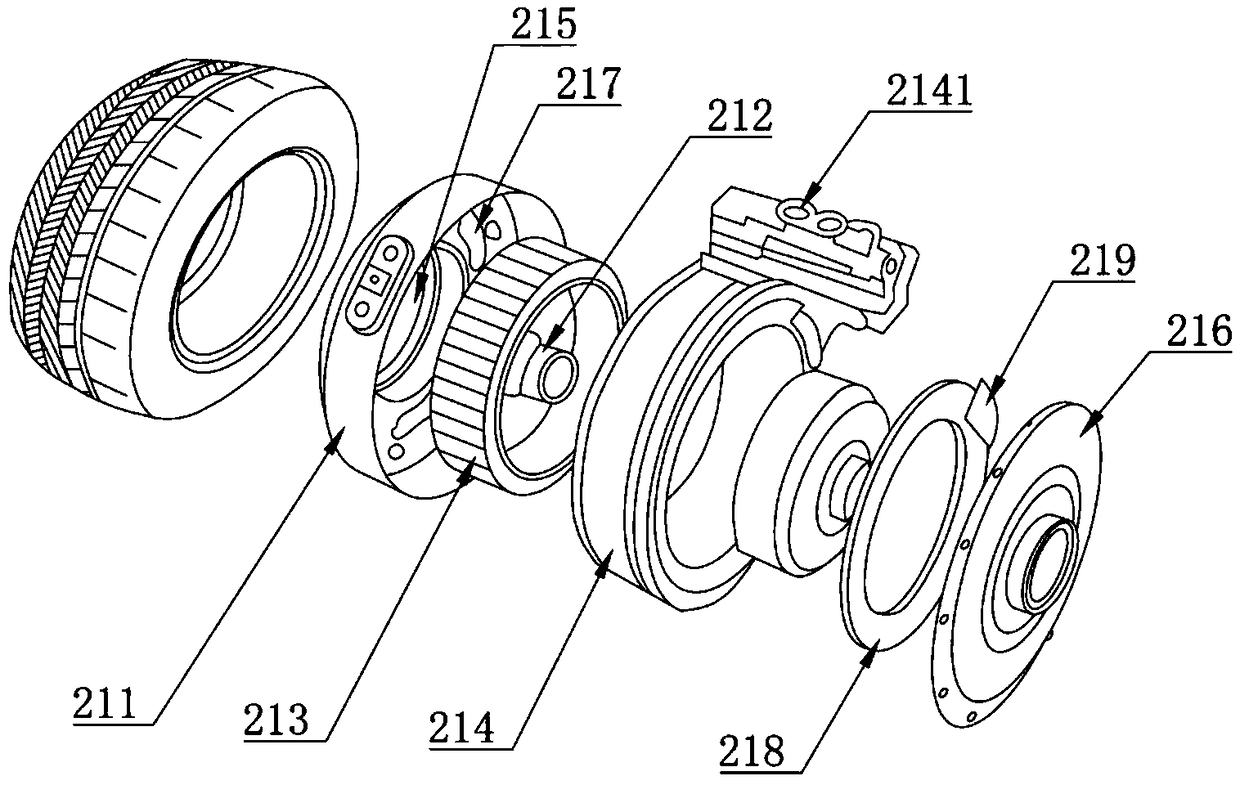

[0022] Such as figure 1 and figure 2 As shown, the present invention provides an electric vehicle that utilizes hub rotation to generate electricity, including a vehicle body 1 , a power generation device 2 and a power transmission mechanism 3 . Automobile body 1 is made up of vehicle body, chassis, tire and other various parts, and power generation device 2 comprises the hub transmission mechanism 21 that is installed on the tire of automobile body 1 and is used for the generator 22 that the mechanical energy of hub transmission mechanism 21 is converted into electric energy, and the hub Transmission mechanism 21 comprises the wheel hub 211 that is installed in the tire inner profile of automobile body 1, the bearing 212 that is used to connect the inner wheel hub 211 of tire on both sides of automobile body 1, is arranged in the wheel hub 211 and is fixed with the permanent magnet rotor 213 of bearing 212 and is arranged on The coil 214 around the permanent magnet rotor 21...

Embodiment 2

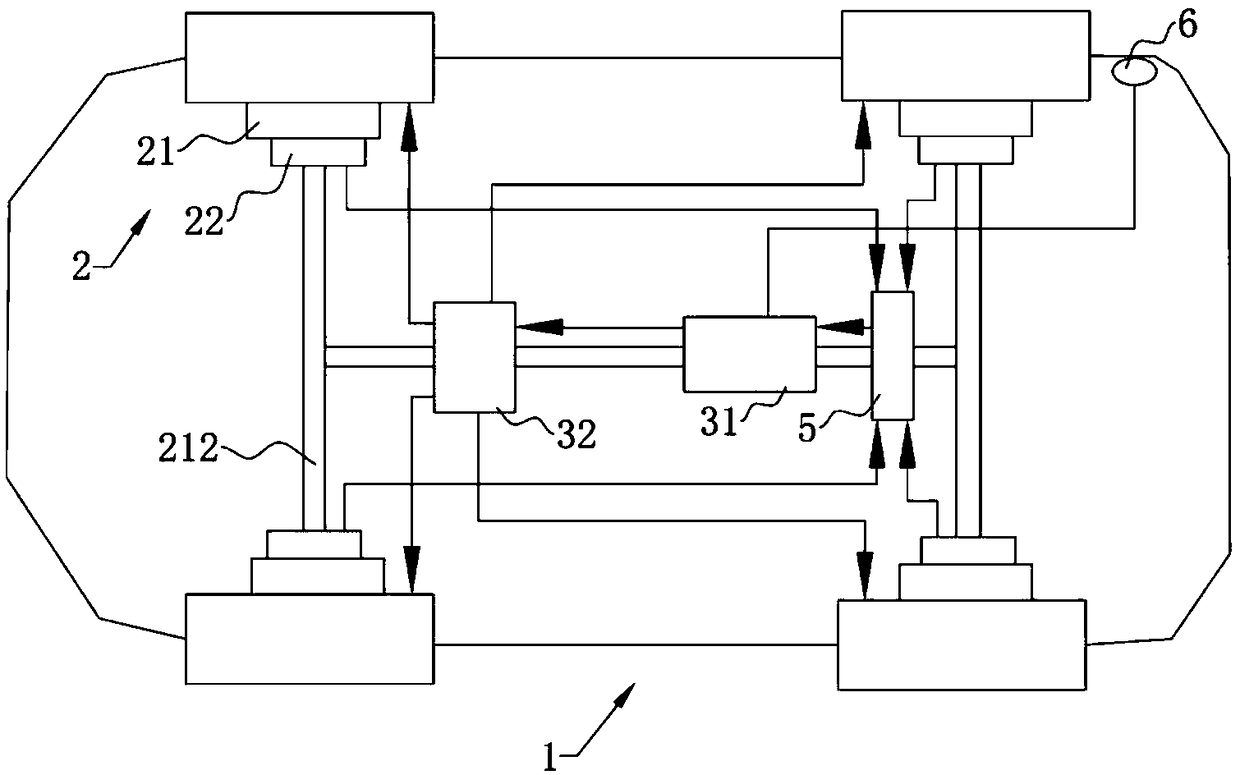

[0026] The difference from Example 1 is that the combination image 3 As shown, a generator 22 is installed at the output end of the wheel hub transmission mechanism 21 on the four tires of the automobile body 1, and a voltage stabilizer 5 is connected to the input end line of the battery pack 31, so that the voltage stabilizer 5 is connected to the four tires respectively. The generator 22 is wired for regulating the output voltage. By arranging a generator 22 on each of the four tires, it is ensured that the kinetic energy of the rotation of the automobile hub 211 is fully collected and utilized and converted into electric energy. In different running states of the car, the power generation is the same at different rotation speeds of the wheel hub 211 , and the voltage stabilizer 5 is used to ensure that the voltage output to the battery pack 31 is stable.

[0027] The electric vehicle of the present invention utilizes the power of the wheel hub 211 to drive the rotor to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com