A heat-setting device for honeycomb porous structure cotton and its application method

A porous structure, heat-setting technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. High utilization rate, strong adjustability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

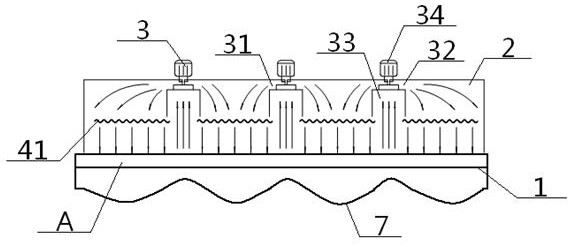

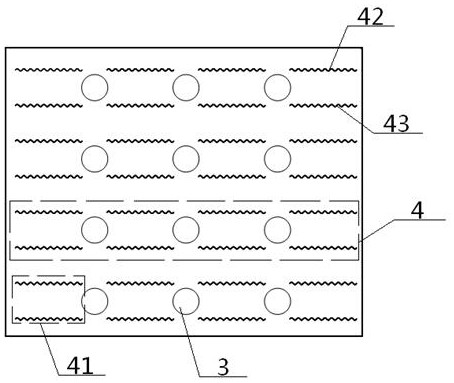

[0050] see Figure 1 to Figure 5 A heat-setting device for honeycomb porous structure cotton, comprising a plurality of fans 3; said heat-setting device comprises at least two heat-setting units 4 arranged side by side in a longitudinal direction, and the spacing between adjacent heat-setting units 4 is consistent; said The heat setting unit 4 includes heating wire groups 41 and fans 3 arranged at intervals along the transverse direction, a fan 3 is arranged between adjacent heating wire groups 41, a heating wire group 41 is arranged between adjacent fan groups 3, and a single heating Wire group 41 comprises up and down symmetrical upper heating wire 42, lower heating wire 43, upper heating wire 42, lower heating wire 43 are parallel to each other, the spacing of upper heating wire 42, lower heating wire 43 is wider than the air suction port 33 of fan 3, fan The left air outlet 31 of 3 and the heating wire group 41 on the left side of the blower fan 3 are arranged facing up an...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

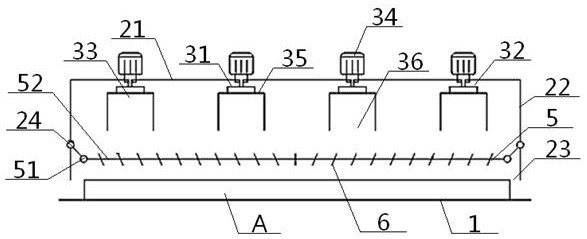

[0054] The heat-setting device also includes an air-distributing net 5, which comprises a rectangular frame 51 and a plurality of air-distributing rods 52 arranged therein. The adjacent air-distributing rods 52 are parallel to each other, and the outside of the rectangular frame 51 The drive rod 24 is flexibly connected to the inner wall of the cylindrical side plate 22, and the inner side of the rectangular frame 51 is connected to the two ends of the air-distributing rod 52. The air-distributing rod 52 is provided with a plurality of air-distributing fins 6, and the air-distributing net 5 It is located between the heating wire group 41 and the conveyor belt 1 .

[0055] When the textile body A is located at the bottom of the feeding bottom port 23, and the blowing operation and the air suction operation are continuing, the driving rod 24 drives the air-distributing net 5 to swing left and right, so as to ...

Embodiment 3

[0057] Basic content is the same as embodiment 2, the difference is:

[0058] The air equalizer rod 52 includes a plurality of pulling rods 53 arranged in sequence and has the same structure. The air equalizer sheet 6 includes an air equalizer ball 61, a movable bead 62 and a fan-shaped piece 63, and the outer surface of the air equalizer ball 61 is uniform. Four fan-shaped pieces 63 are provided, and the fan-shaped pieces 63 are perpendicular to the pulling bar 53. The inside of the uniform wind ball 61 is provided with a left bead cavity 64 and a right bead cavity 65 facing to each other. 64. A movable opening 66 is respectively opened on the opposite outer surface of the right bead cavity 65, a spherical entity 67 is formed between the left bead cavity 64 and the right bead cavity 65, and a movable opening is respectively arranged in the left bead cavity 64 and the right bead cavity 65. Bead 62, the spherical surface facing the movable opening 66 on the movable bead 62 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com