A prefabricated frame structure suitable for high erosion environments such as salt lake areas

A frame structure and prefabricated technology, used in building components, building structures, buildings, etc., can solve the problems of short service life, poor durability, low corrosion resistance and ion corrosion resistance, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

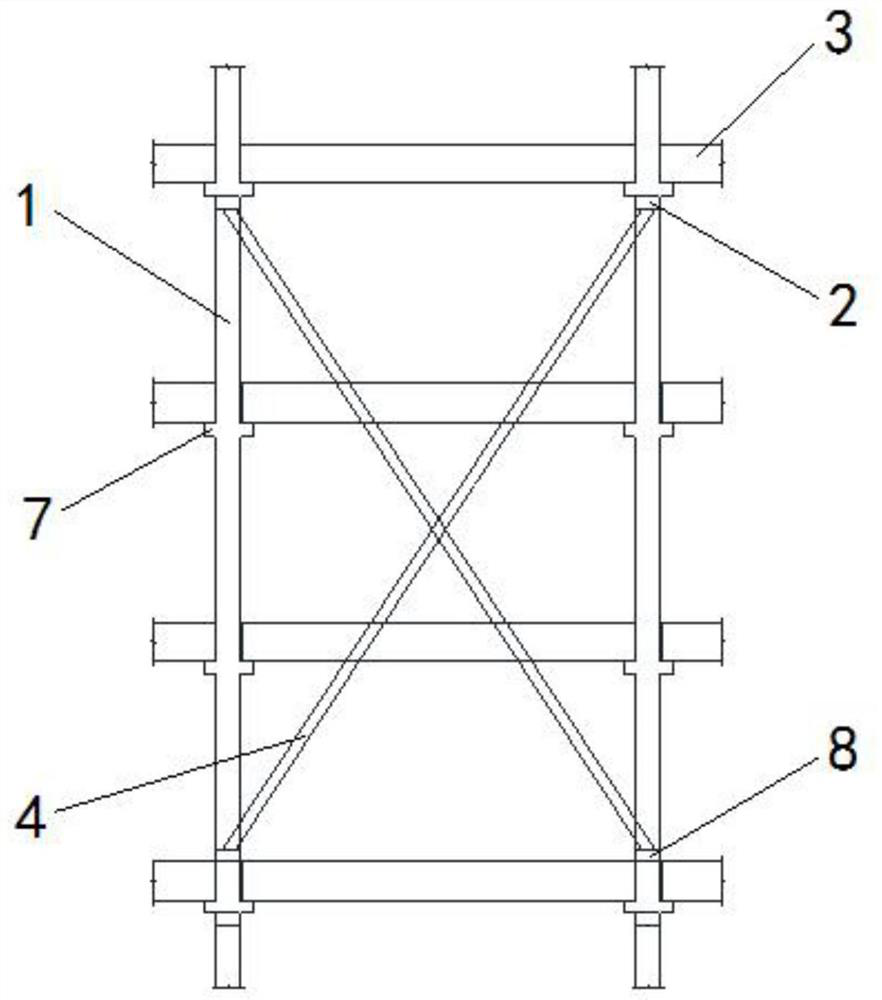

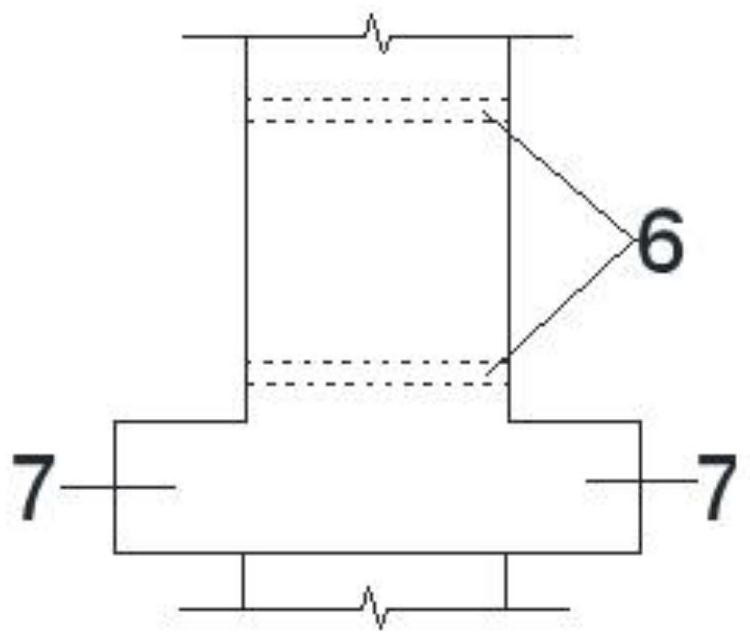

[0016] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 6 and Figure 7 Describe this embodiment. In this embodiment, a prefabricated frame structure suitable for high erosion environments such as salt lake areas uses UHPC solid columns 1 as frame columns, UHPC closed cavity beams 3 as frame beams, and UHPC struts 4 as inter-column columns. The lateral supports are connected; the UHPC solid column 1 is provided with a corbel 7 at each floor height for supporting the UHPC closed cavity beam 3, and the lower end of the uppermost corbel 7 on the UHPC solid column 1 is provided with The upper bump 2, the upper end of the lowermost corbel 7 on the UHPC solid column 1 is provided with a lower bump 8, and the upper bump 2 and the lower bump 8 are provided with a bump reserved for fixing the UHPC strut 4 In the channel 9 , two UHPC struts 4 are intersected and arranged between four UHPC solid columns 1 .

[0017] The height of the corbel is set ...

specific Embodiment approach 2

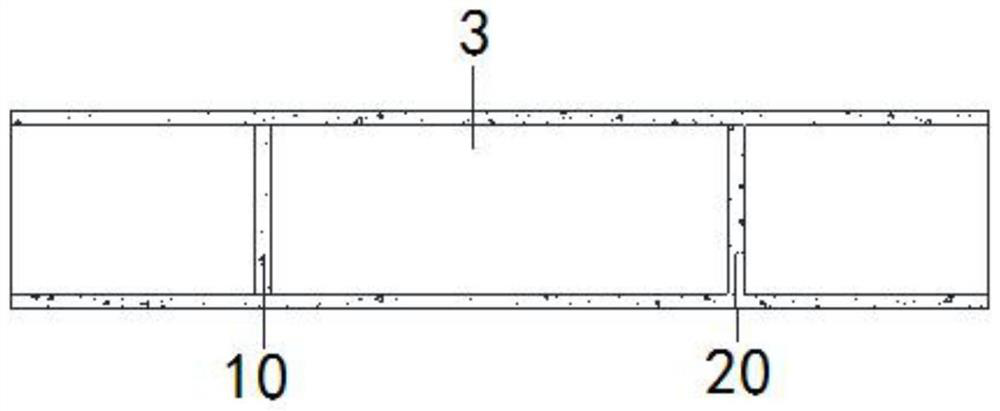

[0019] Specific implementation mode two: combination Figure 4 and Figure 5 This embodiment is described. The difference between this embodiment and specific embodiment 1 is that the UHPC closed cavity beam 3 is prepared according to the following steps: the cavity beam 5 is manufactured by the long-line platform extrusion molding process; the cavity beam 5 is placed on the lifting platform base 14 along the beam length direction; adjust the height of the lifting platform top plate 11, so that the length of the lifting platform top plate 11 from the upper end of the cavity beam 5 meets the anchorage length of the connecting rib 15 on the cavity beam 5, and then in the cavity Pour the first transverse partition 10 in the cavity beam 5; adjust the height of the lifting platform top plate 11 so that the length of the lifting platform top plate 11 from the lower end of the cavity beam 5 meets the anchorage length of the connecting rib 15 in the closed cavity beam 5, and then pass...

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the connection between UHPC solid columns 1 and UHPC struts 4 is carried out according to the following steps: two UHPC struts 4 are cross-placed on four UHPC solid columns 1, pass the prestressed connecting rib 17 out of the reserved hole 9 in the lower bump 8 and then extend into the reserved hole 16 in the UHPC strut 4, and then pass through the UHPC strut 4 The reserved channel 16 of the support rod penetrates into the reserved channel 9 of the bump in the upper bump 2, and the two ends of the prestressed connecting rib 17 withstand the backing plate 18, and the prestressed connecting rib 17 is tensioned and anchored by an anchor 19 , after the prestressed connecting rib 17 is anchored, the anchor is sealed with epoxy resin mortar, that is, the connection between the UHPC solid column 1 and the UHPC strut 4 is completed. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com