Double-rectangular pipe restraint H-shaped section assembling type bending prevention energy consuming support with ribs

An anti-buckling energy-consuming, rectangular tube technology, applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems of insufficient restraint efficiency, limited load, small moment of inertia, etc., to achieve excellent performance, reduce structural cost, and facilitate The effect of processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

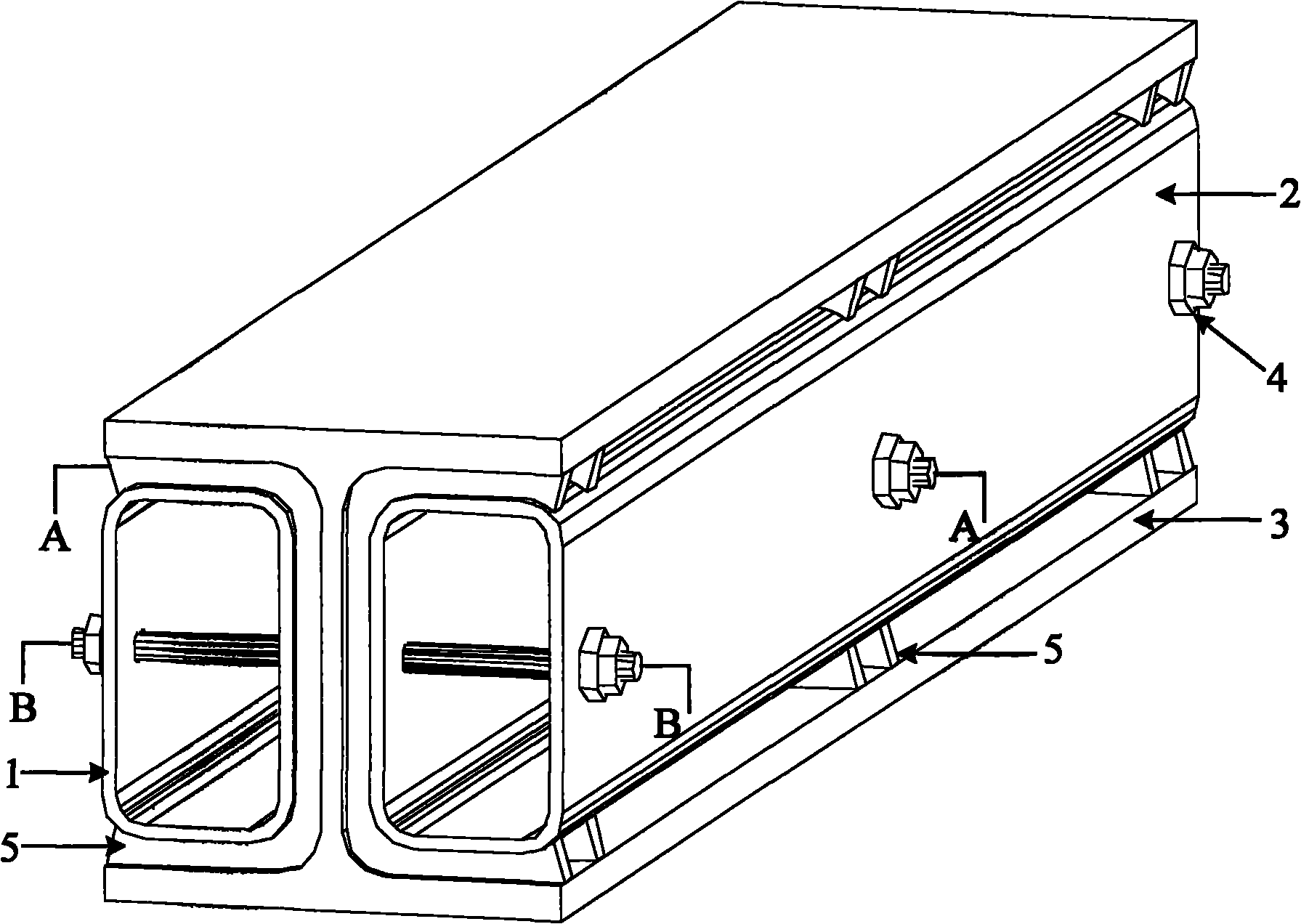

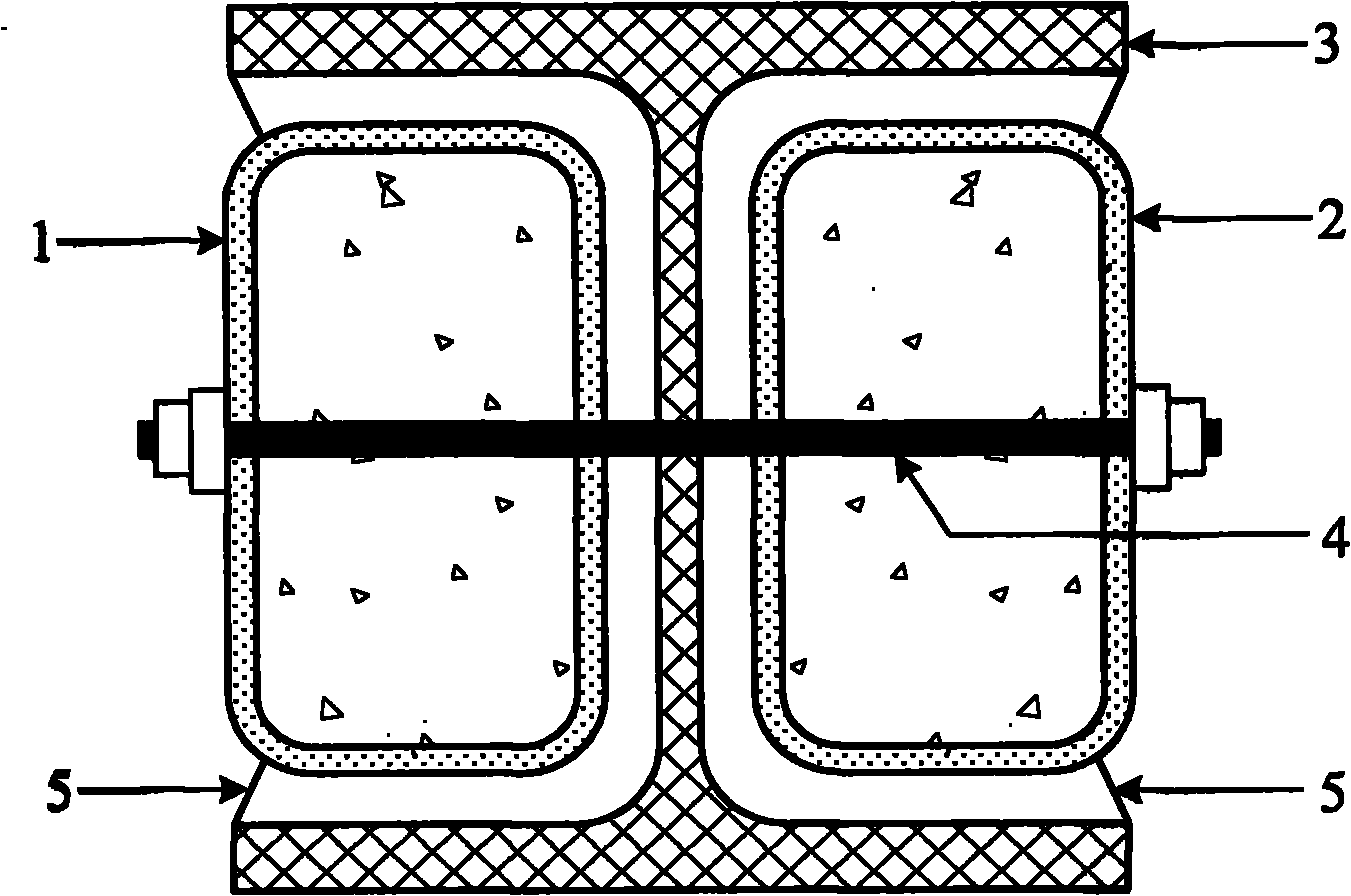

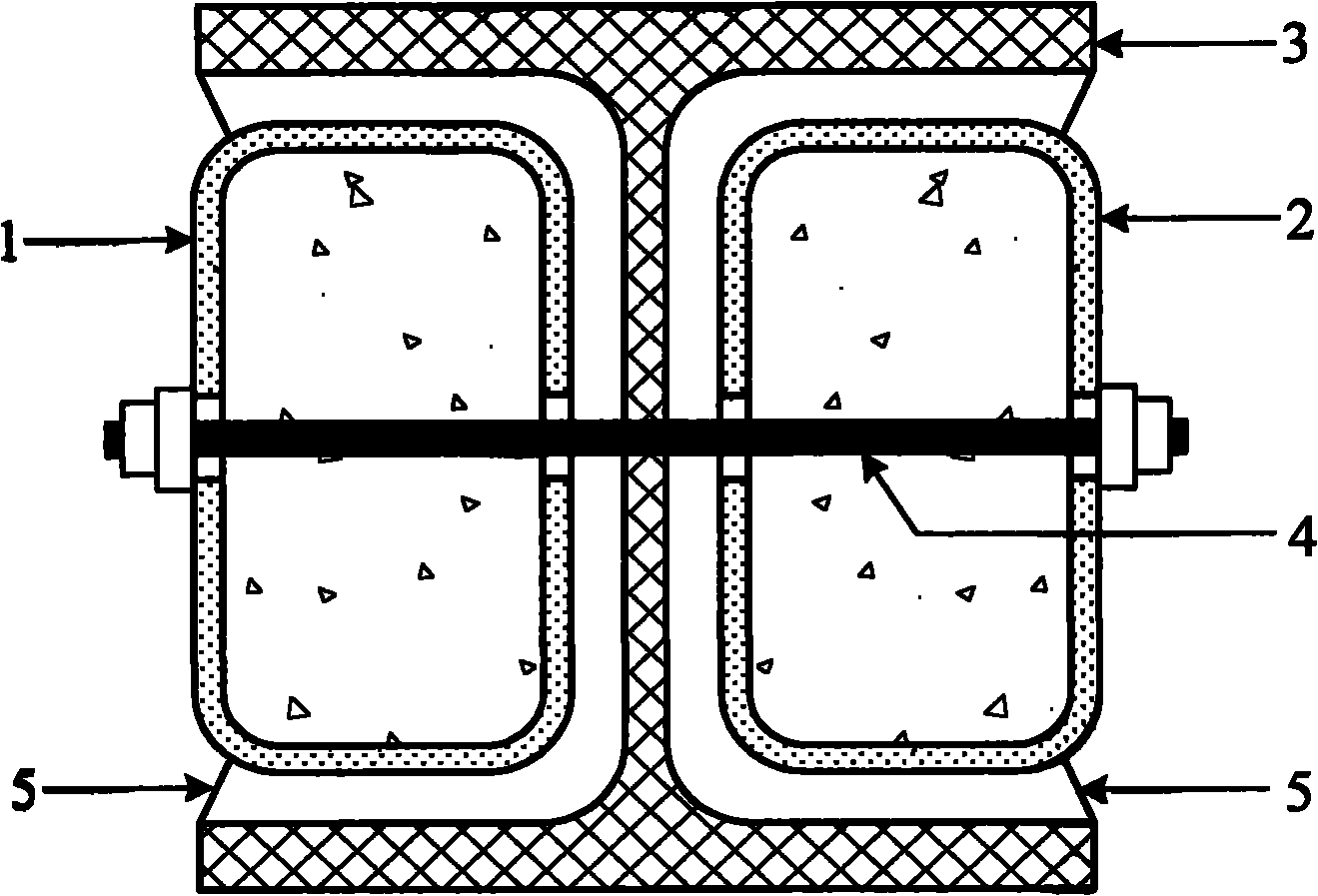

[0022] in such as Figure 1~5 middle:

[0023] 1-Cold-formed thin-walled steel rectangular tube 1

[0024] 2-Cold-formed thin-walled steel rectangular tube 2

[0025] 3- Hot-rolled H-beam

[0026] 4-Long screw connector

[0027] 5-groove stiffener

[0028] like Figure 1 to Figure 3 As shown, the anti-buckling energy-dissipating support is composed of two cold-formed thin-walled steel rectangular tubes 1-2 and a core hot-rolled H-shaped steel 3. Two cold-formed thin-walled steel rectangular tubes 1-2 are welded with groove-shaped stiffeners 5 on three sides close to the hot-rolled H-shaped steel 3, so as to ensure the close contact between the cold-formed thin-walled steel rectangular tubes 1-2 and the hot-rolled H-shaped steel 3; However, there is no welding between the grooved stiffener 5 and the hot-rolled H-shaped steel 3, only contact occurs; two cold-for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com