Box-type cascaded SMA frictional compound damper

A composite damping, series-type technology, applied in building types, protective buildings/shelters, building components, etc., can solve the problems of complex SMA unit structure, low overall stability, and difficulty in starting the damper. Simple structure, wide application range and reasonable force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

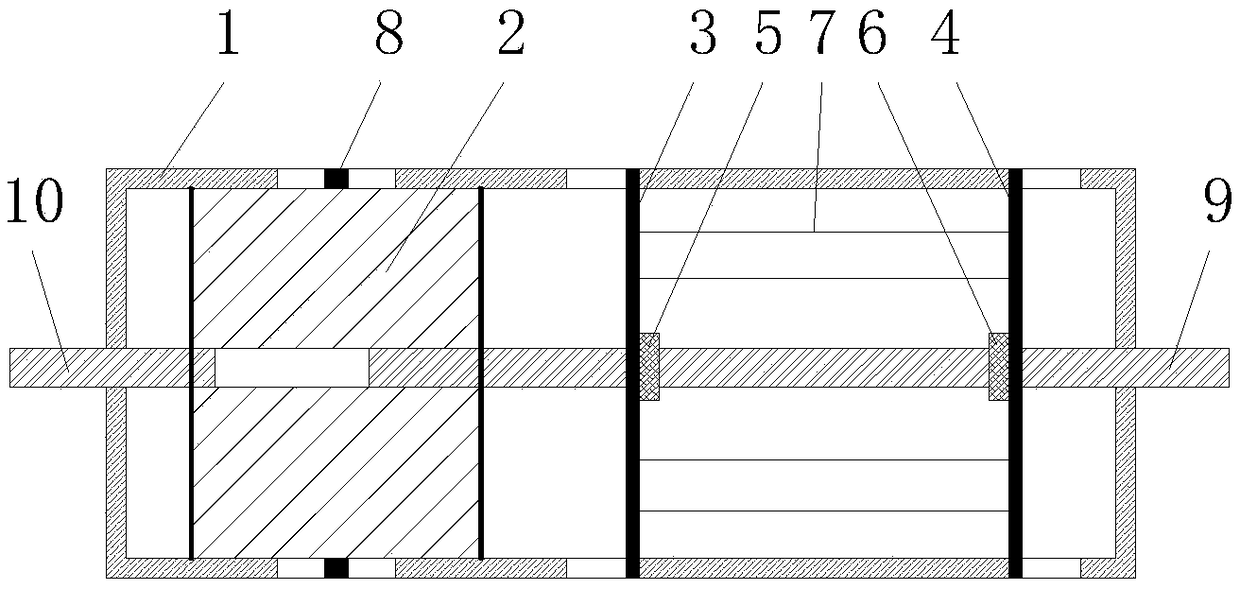

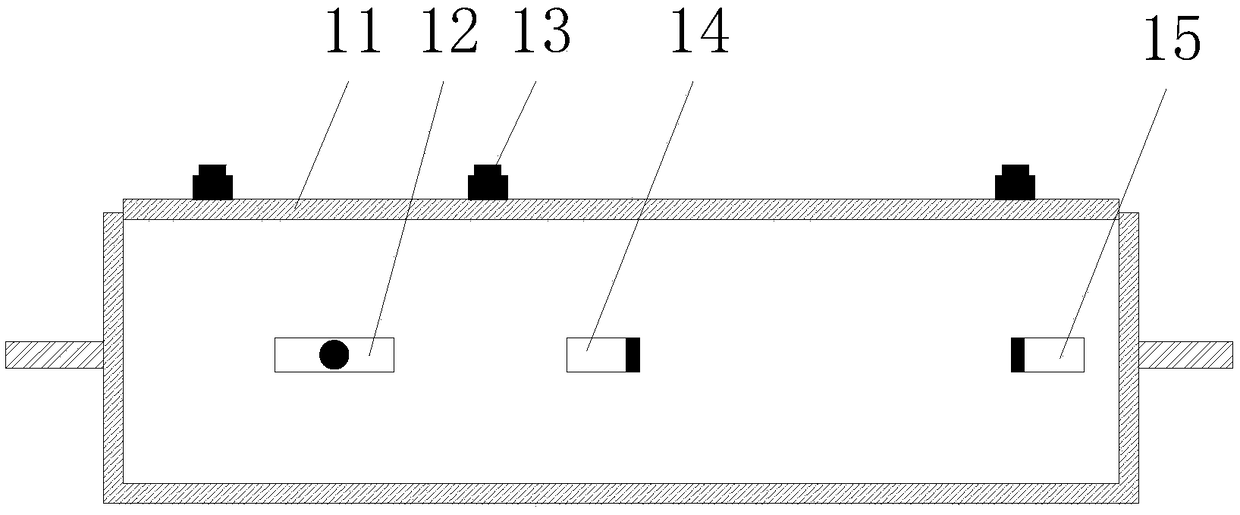

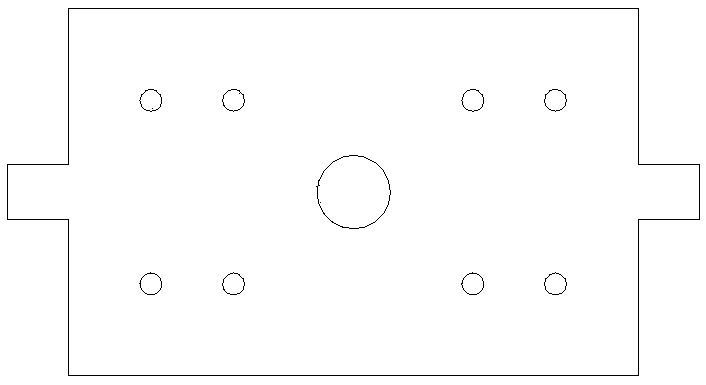

[0023] Such as figure 1 , figure 2 , image 3 As shown, a box-type series-type SMA friction composite damper of the present invention is mainly composed of a damper box 1, a top cover 11, a fixing screw 13, a sliding plate one 3, a sliding plate two 4, an actuating rod one 9, and a circle Shape stopper one 5, circular stopper two 6, SMA wire 7, chute one 14, chute two 15, friction block 2, limit rod 8, limit groove 12 and actuating rod two 10 are formed.

[0024] Among them, sliding plate one 3, sliding plate two 4, actuating rod one 9, circular stopper one 5, circular stopper two 6, and SMA wire 7 form an SMA wire energy consumption unit; friction block 2, limit rod 8 And actuating rod two 10 form frictional energy consumption unit. In order to ensure a large earthquake, the SMA wire energy consumption unit works first, and then the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com