Adaptive controlled mine return air waste heat recovery heating system

A technology of self-adaptive control and mine return air, which is applied in the heating system, mine/tunnel ventilation, household heating, etc., and can solve the problems of low efficiency of total heat exchange, large wind shaft resistance, and low adaptability of atmospheric environment parameters, etc. problems, to achieve the effect of solving low adaptability of heat and moisture exchange efficiency, improving accuracy and targeting, and obvious energy saving and water saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

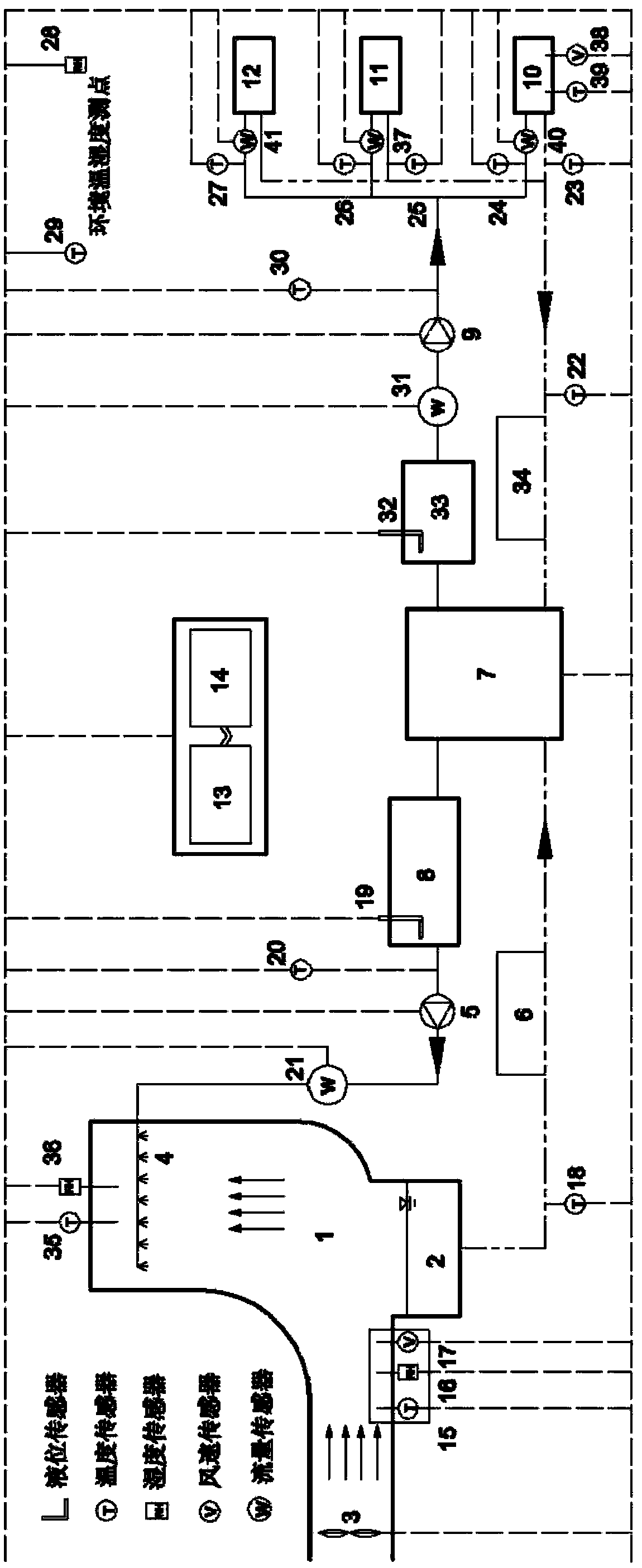

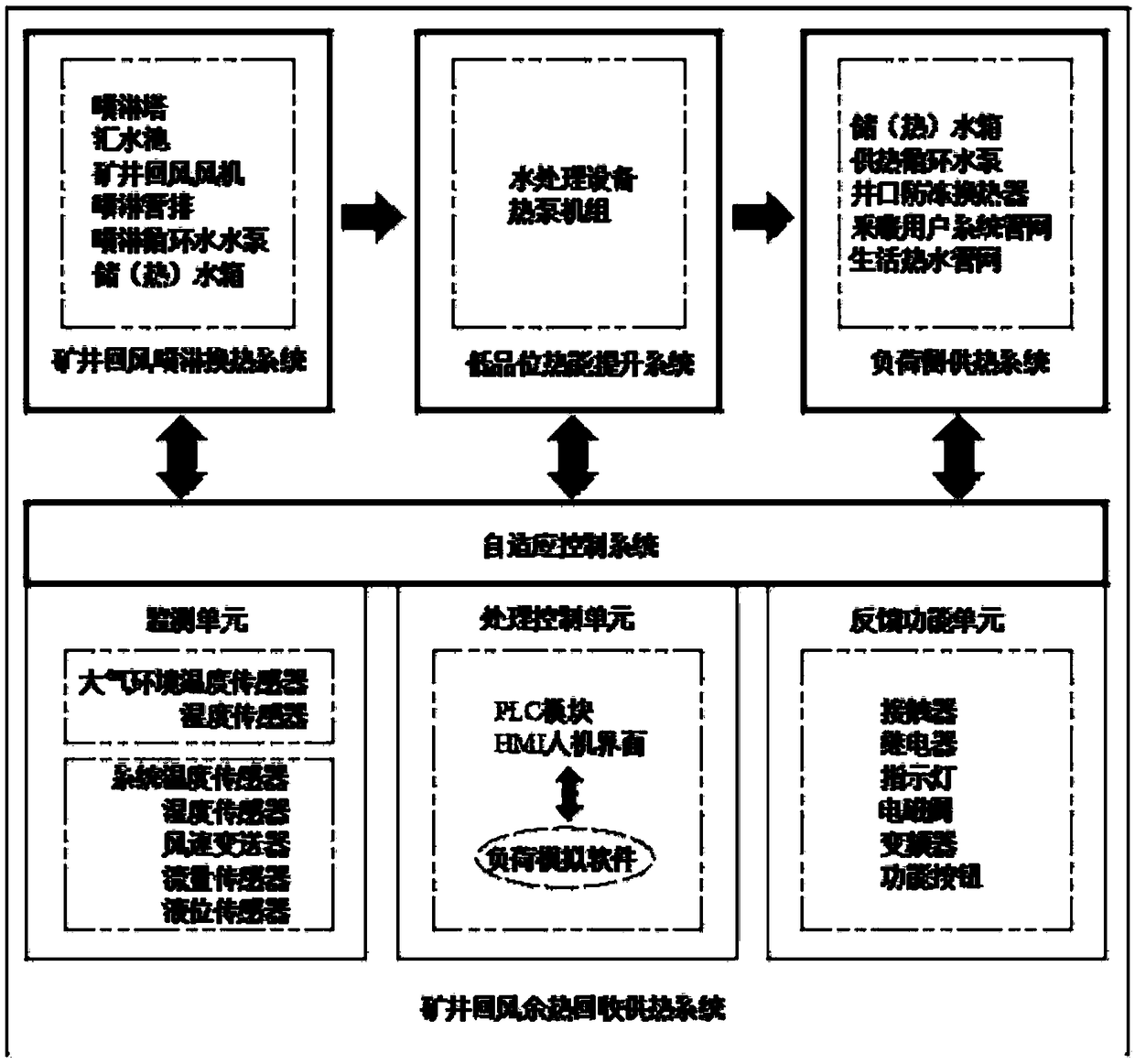

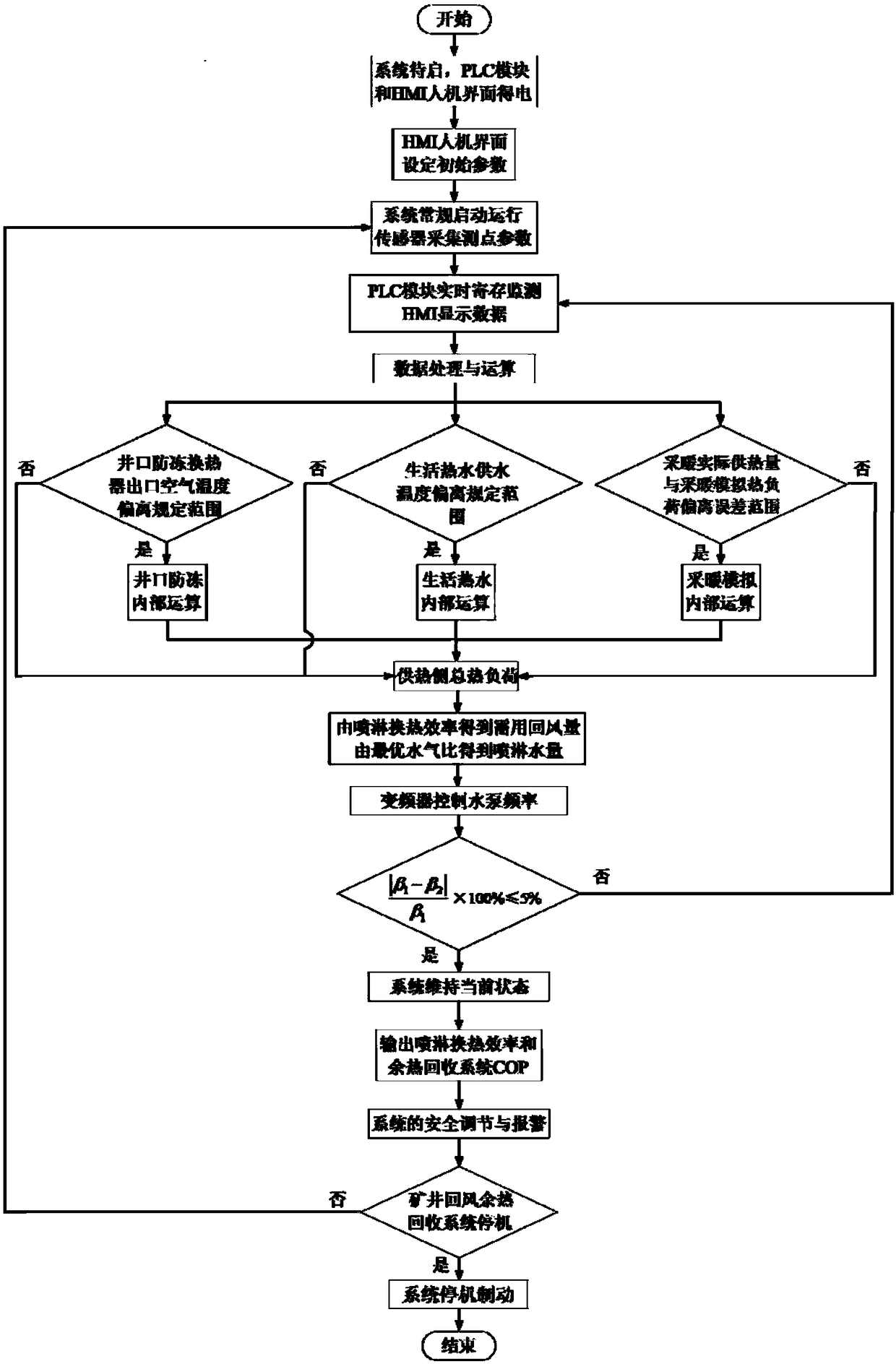

[0024] like figure 1 , 2 , 3, a kind of self-adaptive control mine return air waste heat recovery heating system, the present invention is based on the basic theory of thermodynamics and heat and mass transfer, in the process of countercurrent heat and mass transfer of air and water of a certain quality, air and water The water performs total heat exchange, and the air becomes saturated humid air, and the temperature of the saturated humid air is the same as that of water. This process is called the gas-water ideal heat and mass transfer process. The heat and mass transfer energy conservation formula in this process is: c p,air G air (T air,in -T air,out )+γG air (d air,in -d air,out ) = c w W(T w,in -T w,out ), where c p,air is the specific heat capacity of moist air; G air is the mass of humid air; T air,in is the inlet dry bulb temperature of humid air; T air,out is the dry bulb temperature of the wet air outlet (the temperature of saturated wet air); γ is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com