Nitrogen cooling tower

A nitrogen cooling, nitrogen technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as poor cooling effect and slow cooling speed, and reduce maintenance and cleaning workload , Easy to operate, effective control of nitrogen flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

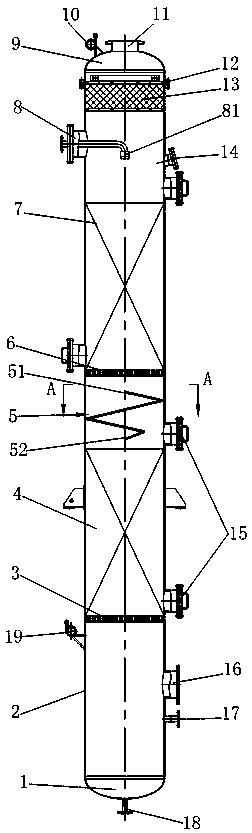

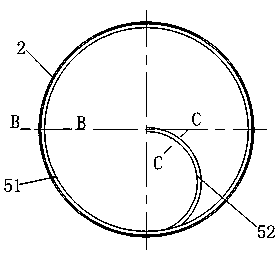

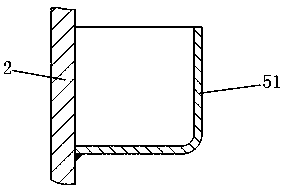

[0016] Such as Figure 1~4 As shown, the present invention includes a cylinder body 2, an upper head 9 and a lower head 1 are fixedly arranged at the upper and lower ends of the cylinder 2, the lower head 1 is provided with a cooling water outlet 18, and the upper head 9 is provided with nitrogen gas The outlet 11 and the upper pressure gauge interface 10, the second filler 7, the second filler grid 6, the deflector 5, the first filler 4, and the first filler grid 3 are sequentially arranged in the cylinder body 2 from top to bottom. Both the second filler 7 and the first filler 4 adopt Pall rings, and the cylinder 2 above the second filler 7 is provided with a spray device 8, and the spray head 81 of the spray device 8 extends to the center of the cylinder 2, and the first filler A nitrogen inlet 16 and a lower pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com