Solar cell string structure

A technology of solar cells and batteries, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to remove battery ribbons, require high welding precision, and affect the aesthetics of components, so as to achieve no optical loss and increase power generation , the effect of area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with accompanying drawing:

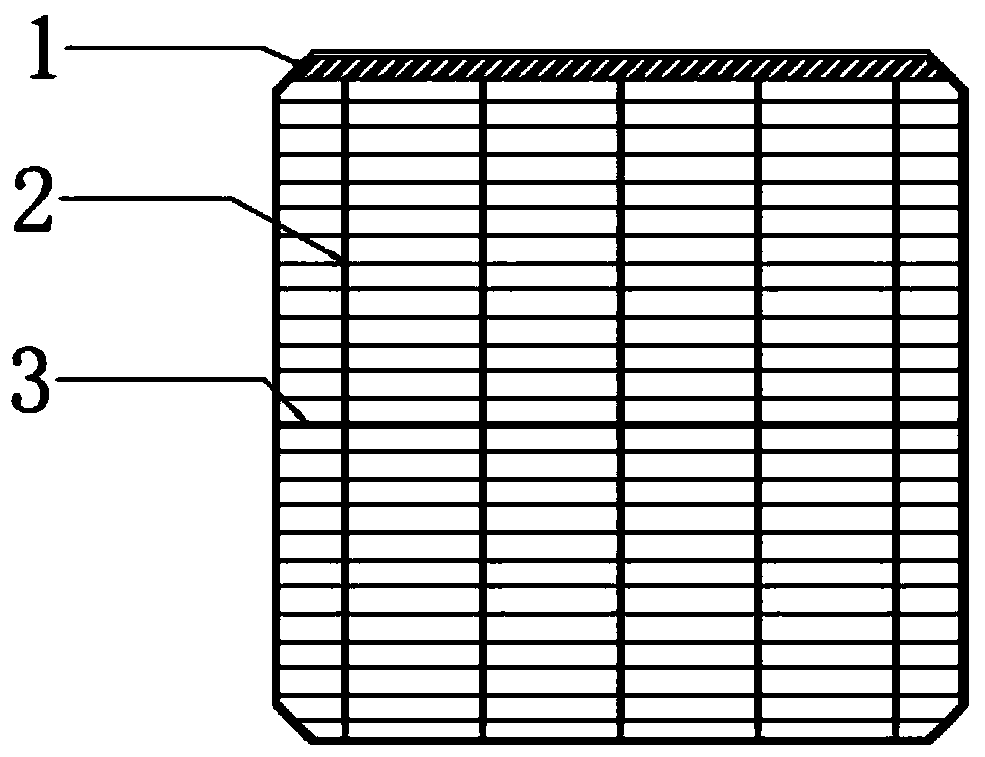

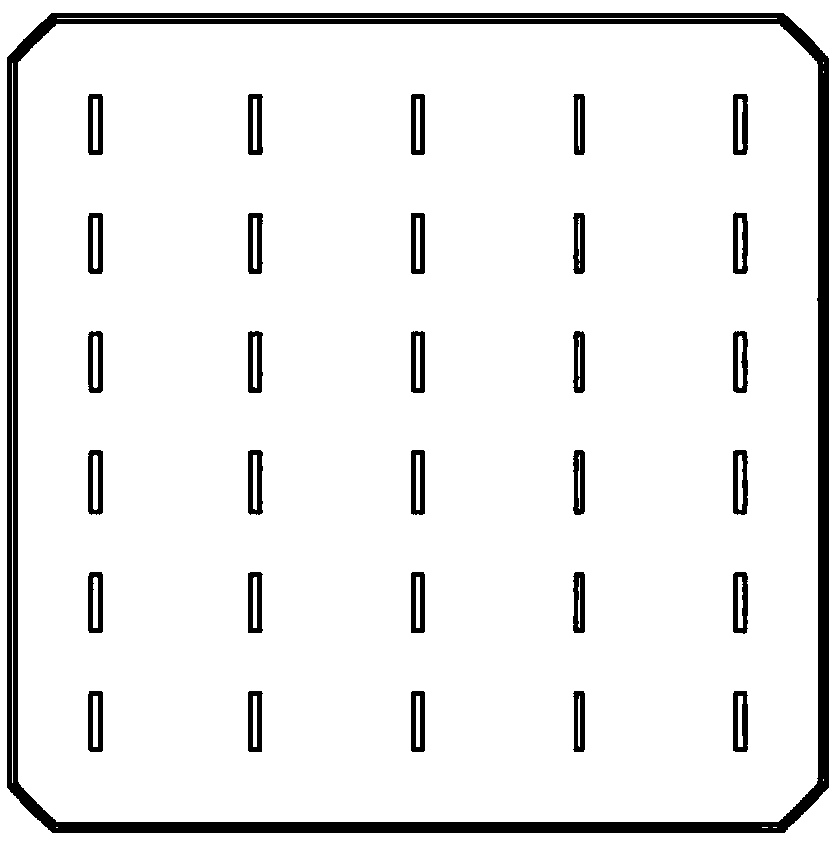

[0022] see Figure 1-Figure 2 , a solar battery string structure, including a plurality of battery slices connected in sequence to form a battery string, and the battery slices include a battery slice main body 8, a bus grid line 1, a main grid line 2, and an auxiliary grid line 3; both sides of the battery slice main body 8 are provided with Bus grid lines 1, main grid lines 2 and auxiliary grid lines 3; several main grid lines 2 and several auxiliary grid lines 3 are arranged on the surface of the cell main body 8 in a staggered connection; the bus grid lines 1 are along the edge of one end of the battery sheet main body set, and the bus bar 1 is connected to the main bar 2.

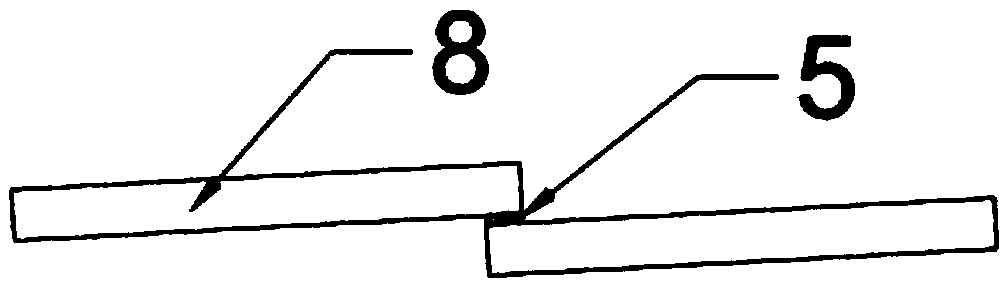

[0023] The battery slices are connected by welding ribbon 5 to form a battery string; the bus grid line 1 on the lower surface of the previous battery slice in the battery string is connected to the bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com