Extreme learning machine based brushless direct current motor and position sensor less control method

An extreme learning machine, brushed DC motor technology, applied in the current controller, electronic commutator and other directions, can solve the problems of low precision, difficult to use motor operation requirements, etc., to achieve fast learning rate, good dynamic performance, improve The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

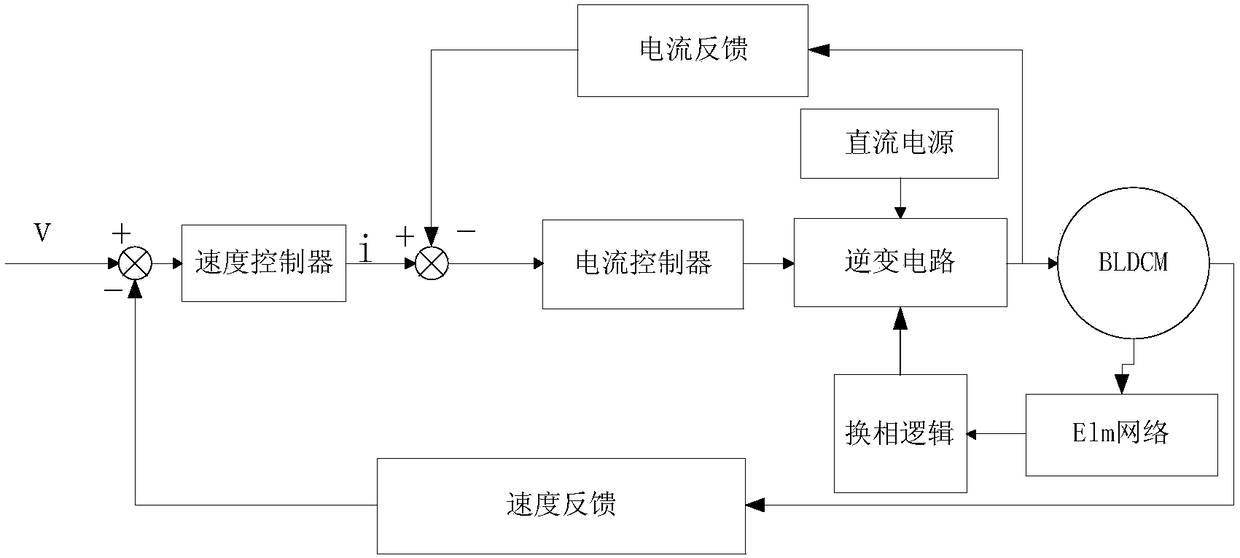

[0042] The brushless DC motor position sensorless control method based on the extreme learning machine proposed by the present invention is described in detail as follows in combination with the control system structure diagram:

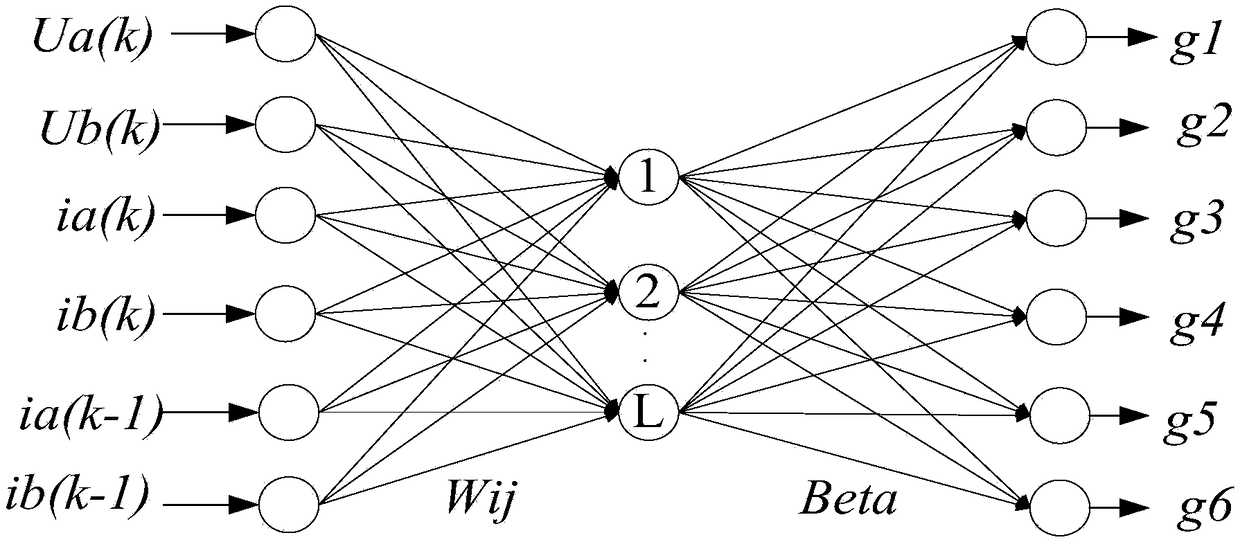

[0043] Phase 1: Network training phase, consisting of figure 1 It can be seen that the number of neurons in the input layer of the ELM network is 6, and the number of neurons in the output layer is 6. Its training steps are as follows:

[0044]The training data and test data are obtained by simulating the position sensor brushless DC motor through MATLAB, and the measured 5000 sets of training data and 2500 sets of test data are normalized;

[0045] Step2: Determine the number of neurons in the hidden layer, write a for loop program with the M file, embed the ELM program inside the loop, and initialize the number of hidden layer nodes, so that the number of hidden layer nodes increases continuously, and the number of hidden layers increases When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com