Honeysuckle screening and refining equipment

A honeysuckle and screening technology is applied in the field of honeysuckle screening and refining equipment, and can solve the problems of increasing the refining and processing cost of honeysuckle, not easily separating leaves and flowers, and reducing the refining and processing efficiency of honeysuckle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

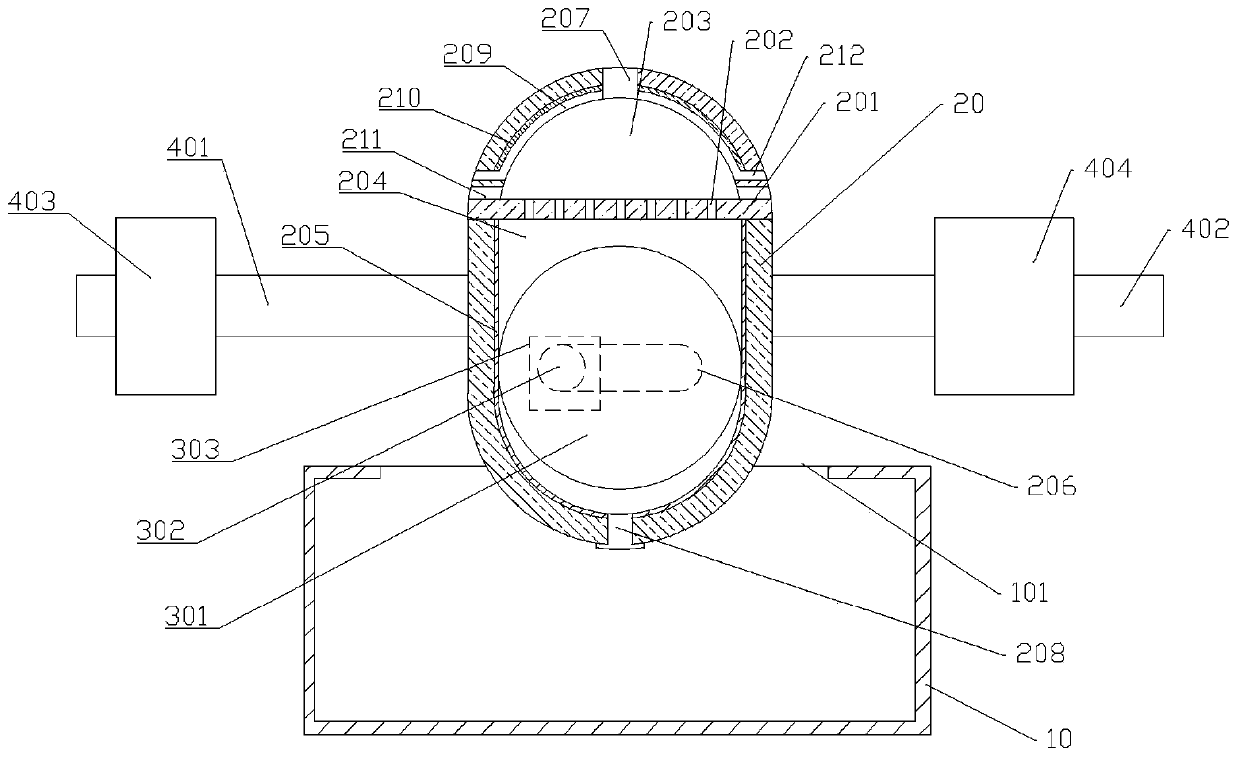

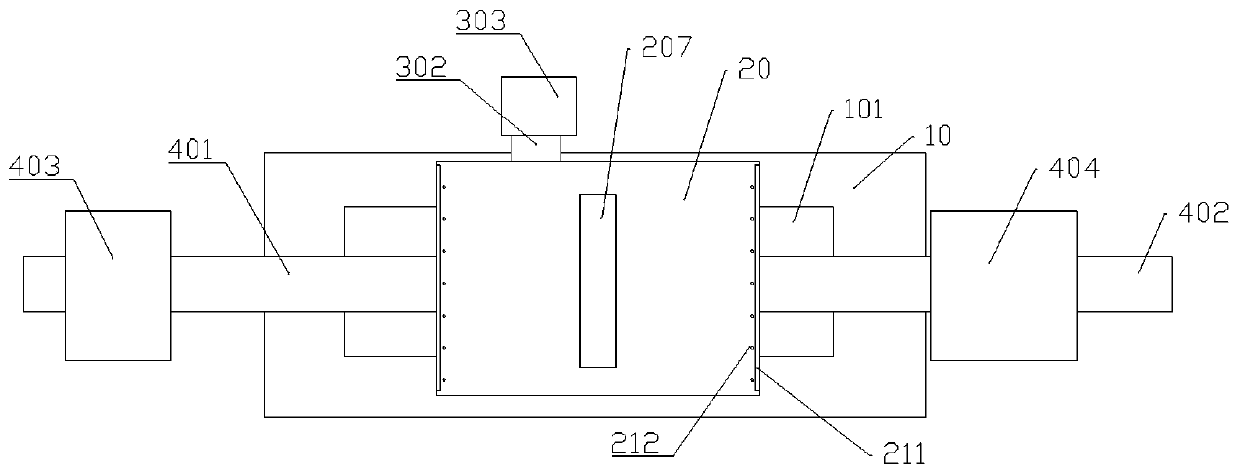

[0017] The reference signs in the drawings of the description include: refining box 10, feeding port 101, processing box 20, heating plate 201, filter hole 202, drying chamber 203, grinding chamber 204, transmission gear 205, chute 206, feeding port 207, discharge port 208, diversion groove 209, absorbent cotton 210, slag discharge port 211, water discharge hole 212, grinding gear 301, rotating shaft 302, motor 303, first slide bar 401, second slide bar 402, first slide bar Block 403 , second slider 404 .

[0018] The embodiment is basically as attached figure 1 And attached figure 2 Shown: honeysuckle sieving and refining equipment, including a refining box 10 and a screening mechanism, and the refining box 10 is provided with a feeding port 101 .

[0019] The screening mechanism includes processing box 20, grinding gear 301, heating plate 201, rotating shaft 302, motor 303 and support unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com