Welding robot with automatic welding slag removing function

A welding robot and automatic cleaning technology, applied in welding equipment, welding equipment, welding accessories and other directions, can solve the problems of residue, reduced safety performance of welding robots, and difficulty in cleaning welding slag in time, so as to avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

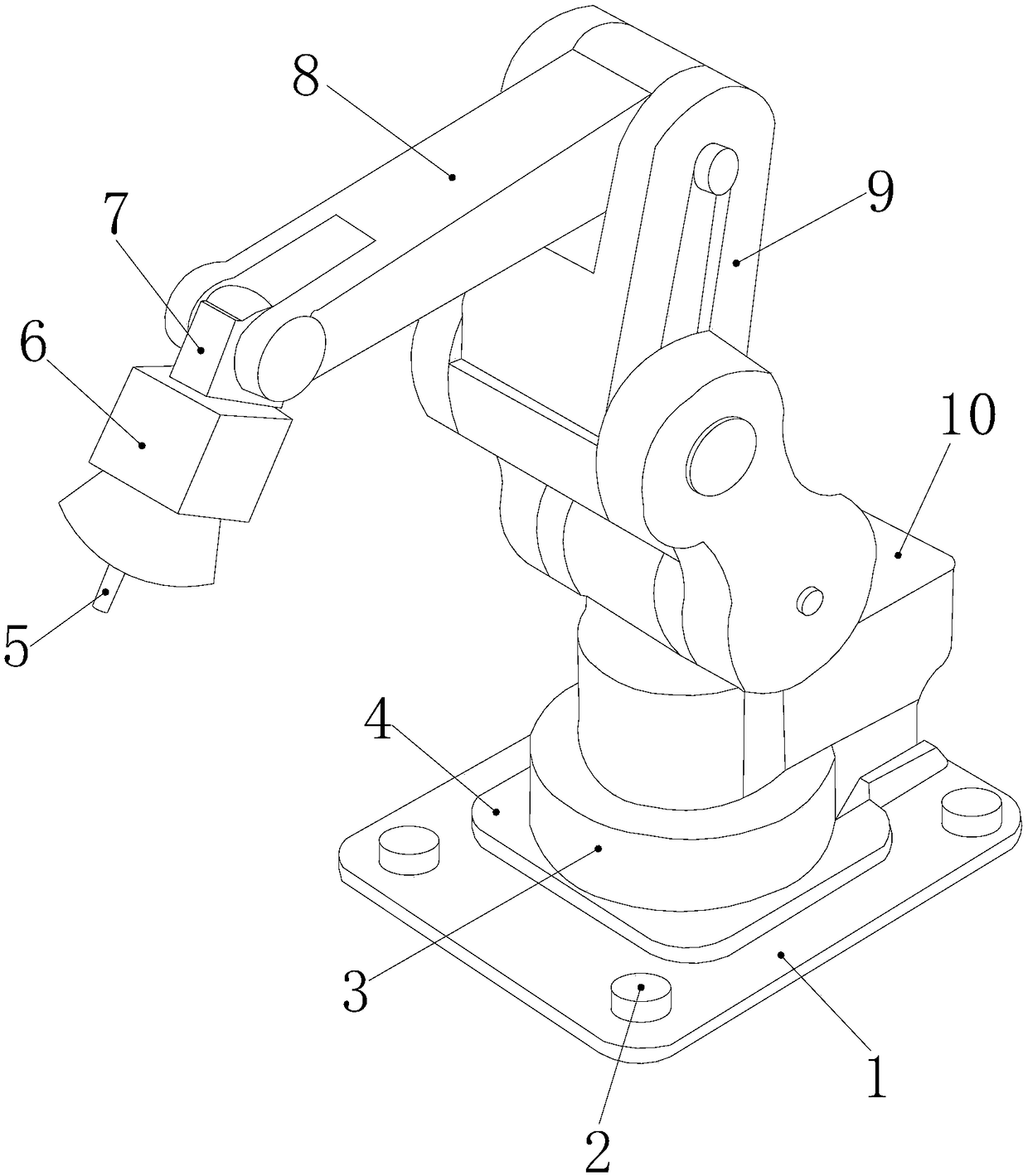

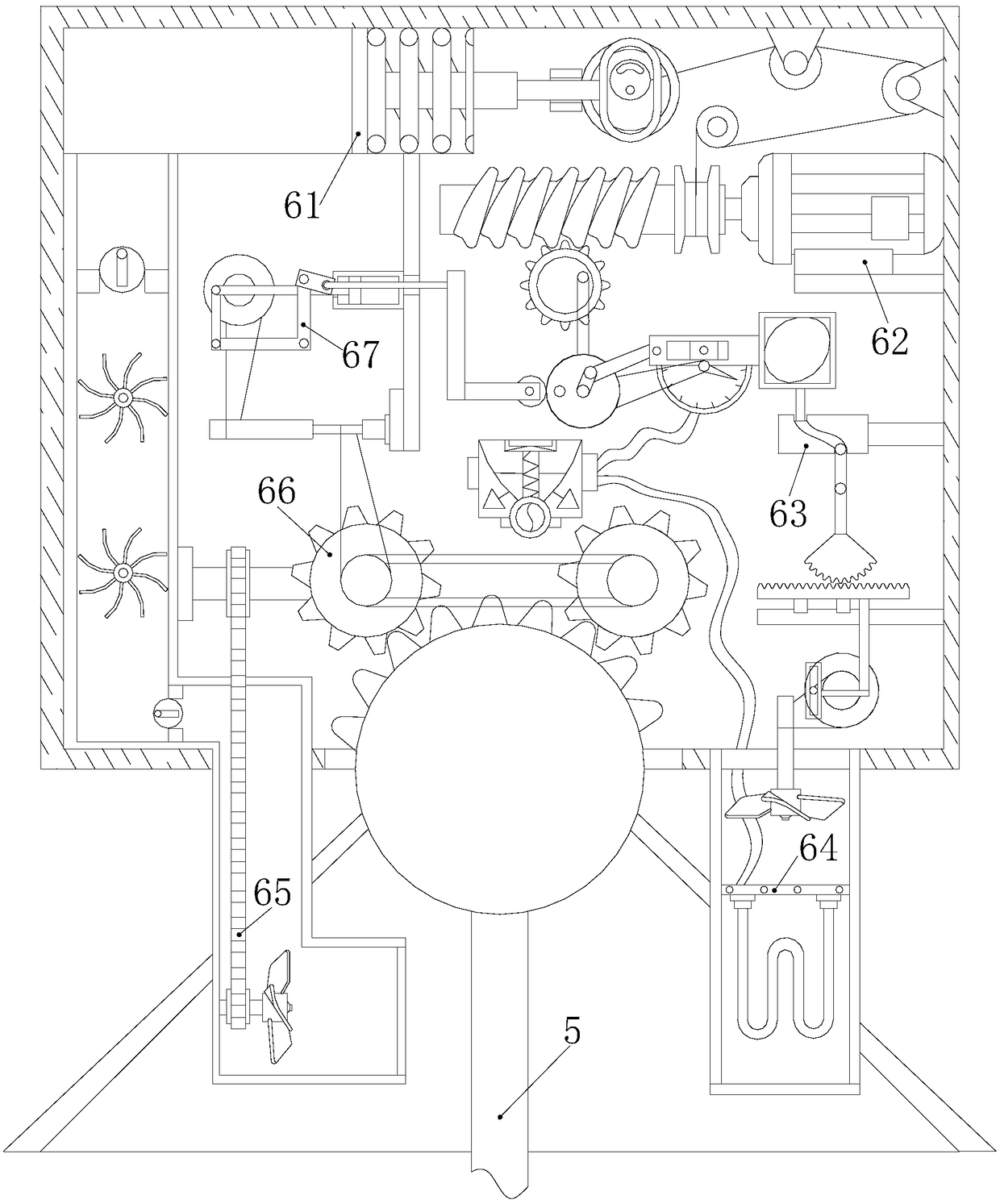

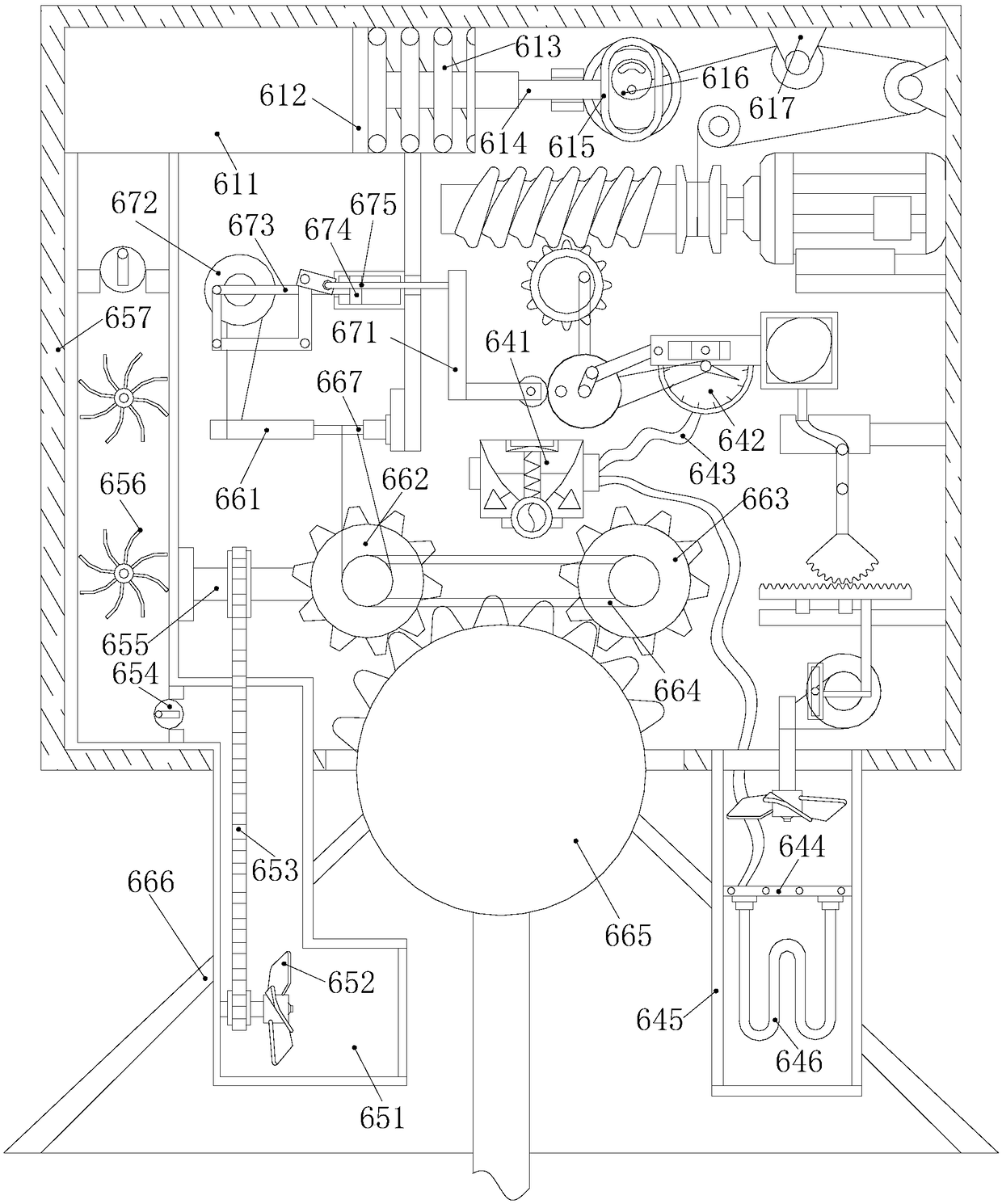

[0022] see Figure 1-Figure 4 , the present invention provides a welding robot with the function of automatically cleaning welding slag: its structure includes: a mounting base plate 1, a limit screw 2, a junction box 3, an anti-skid plate 4, a welding torch 5, a welding slag cleaning device 6, a connecting block 7, Small arm 8, large arm 9, motor box 10, half of the upper surface of the installation base plate 1 is attached to the lower surface of the anti-skid plate 4, and four limit screws 2 are installed in the On both sides of the anti-skid plate 4, the lower end of the limit screw 2 is connected to both sides of the installation base plate 1 in a nested manner and threaded, and the lower end of the junction box 3 and the upper end of the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com