Dual-purpose assembly for tracks

An assembly and dual-purpose technology, applied in the field of dual-purpose rail vehicles, can solve problems such as the inability to meet the requirements of higher and higher rail speeds, unfavorable functional vehicles replaced with other functional devices, and the impact of long-distance transitions on highways. , to achieve the effect of quick disassembly and assembly, reduced time, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific examples.

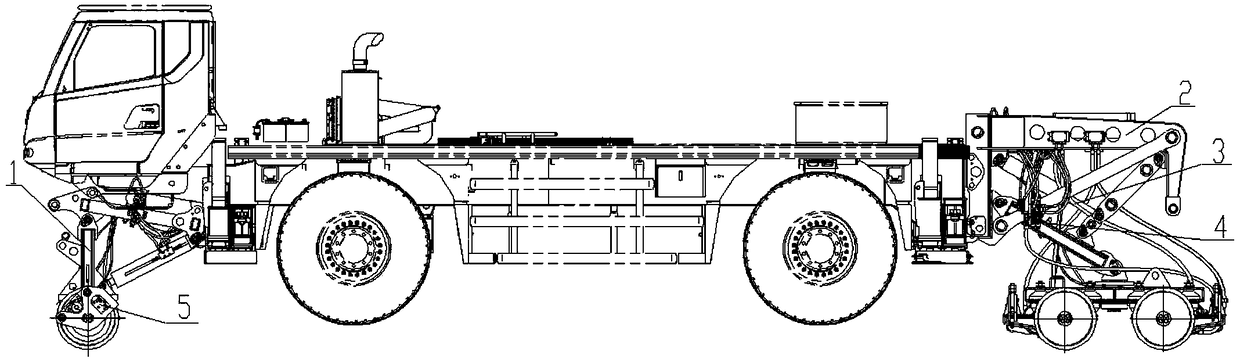

[0042] Such as Figure 1 to Figure 5 Shown is a rail dual-purpose assembly, including a front support assembly 1, a rear bogie assembly 2, a hydraulic system 3, an electrical system 4, and a braking system 5.

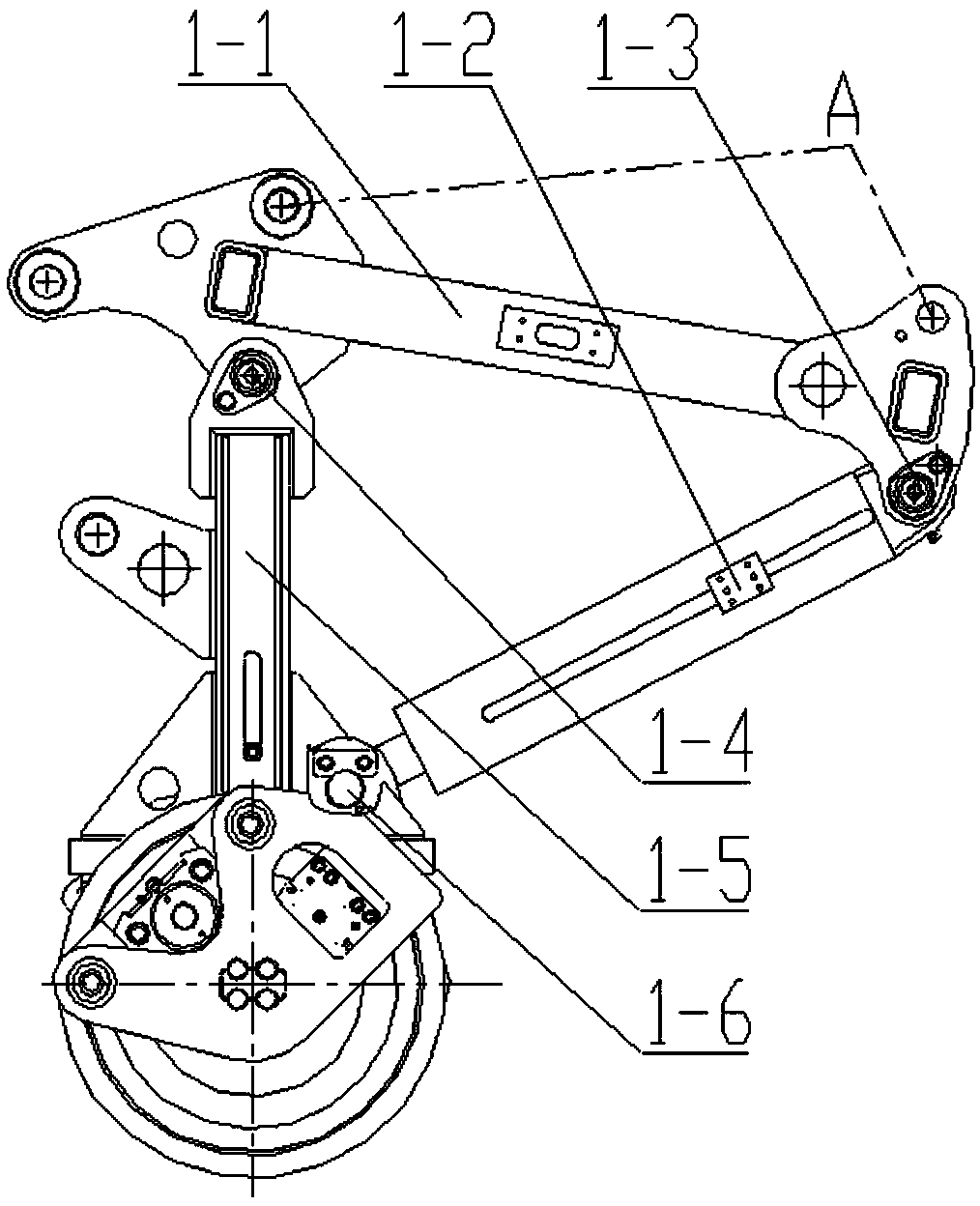

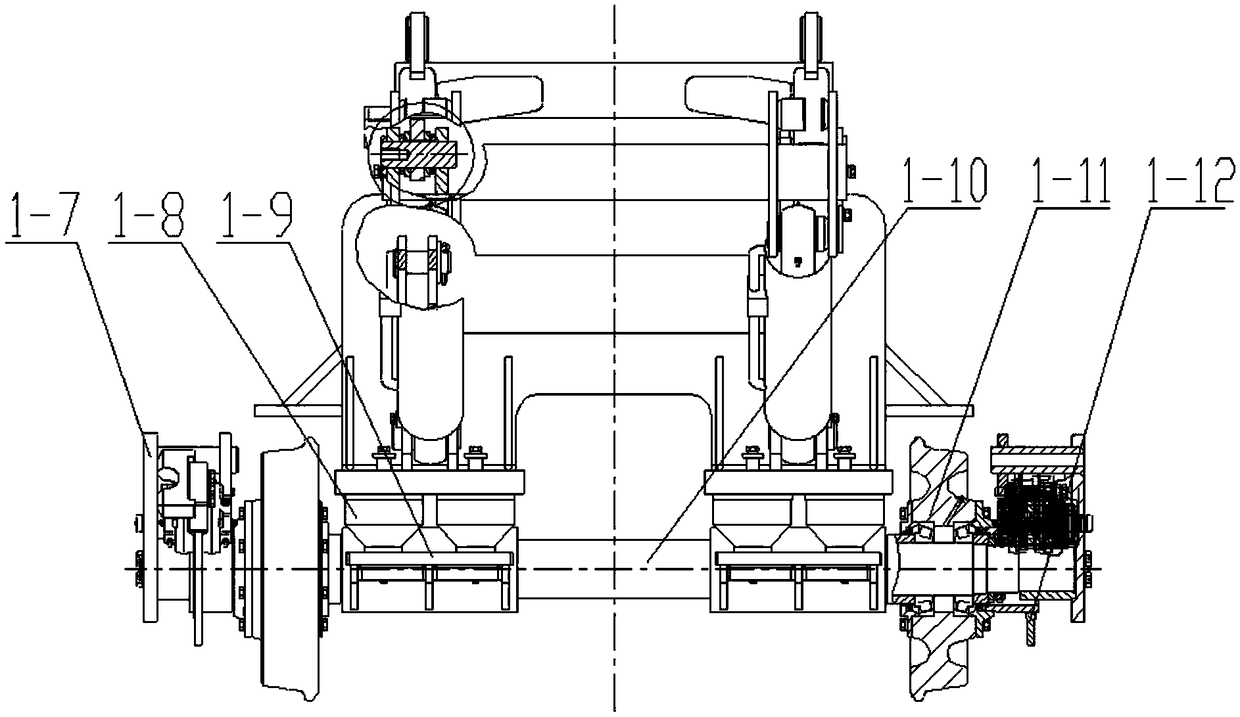

[0043] 1) if Figure 2a , Figure 2bAs shown, the front support assembly 1 is connected to the chassis through the pin shaft through the hinge holes A on both sides, and the male head of the electro-hydraulic pipeline and the chassis correspond to the integrated electro-hydraulic quick-change panel corresponding to the chassis through quick-plug and quick-change joints. The female head of each pipeline realizes quick connection. The front support assembly mainly includes: transition bracket 1-1, front support cylinder 1-2, cylinder barrel end pin 1-3, main yaw pin 1-4, main yaw frame 1-5, cylinder rod end pin 1-6, brake support 1-7, first series cone spring 1-8, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com