Closed-loop management system for potential safety hazards in production

A hidden safety hazard and management system technology, applied in the field of production safety hidden danger closed-loop management system, can solve problems such as delayed transmission of hidden danger information, accidents, loss of life, property, etc., to improve accident prevention capabilities, improve management levels, and strengthen supervision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

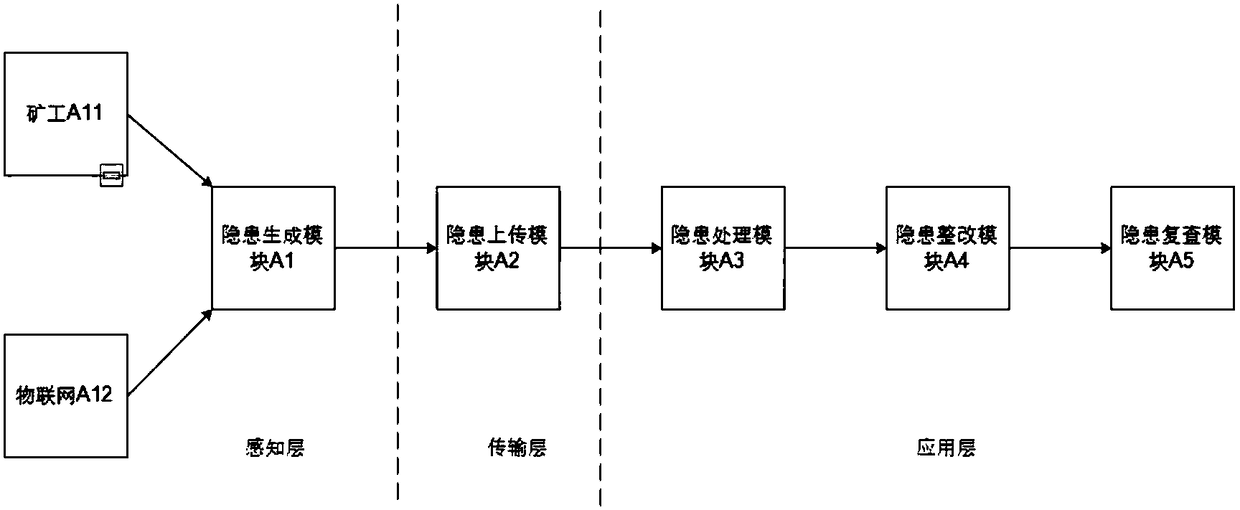

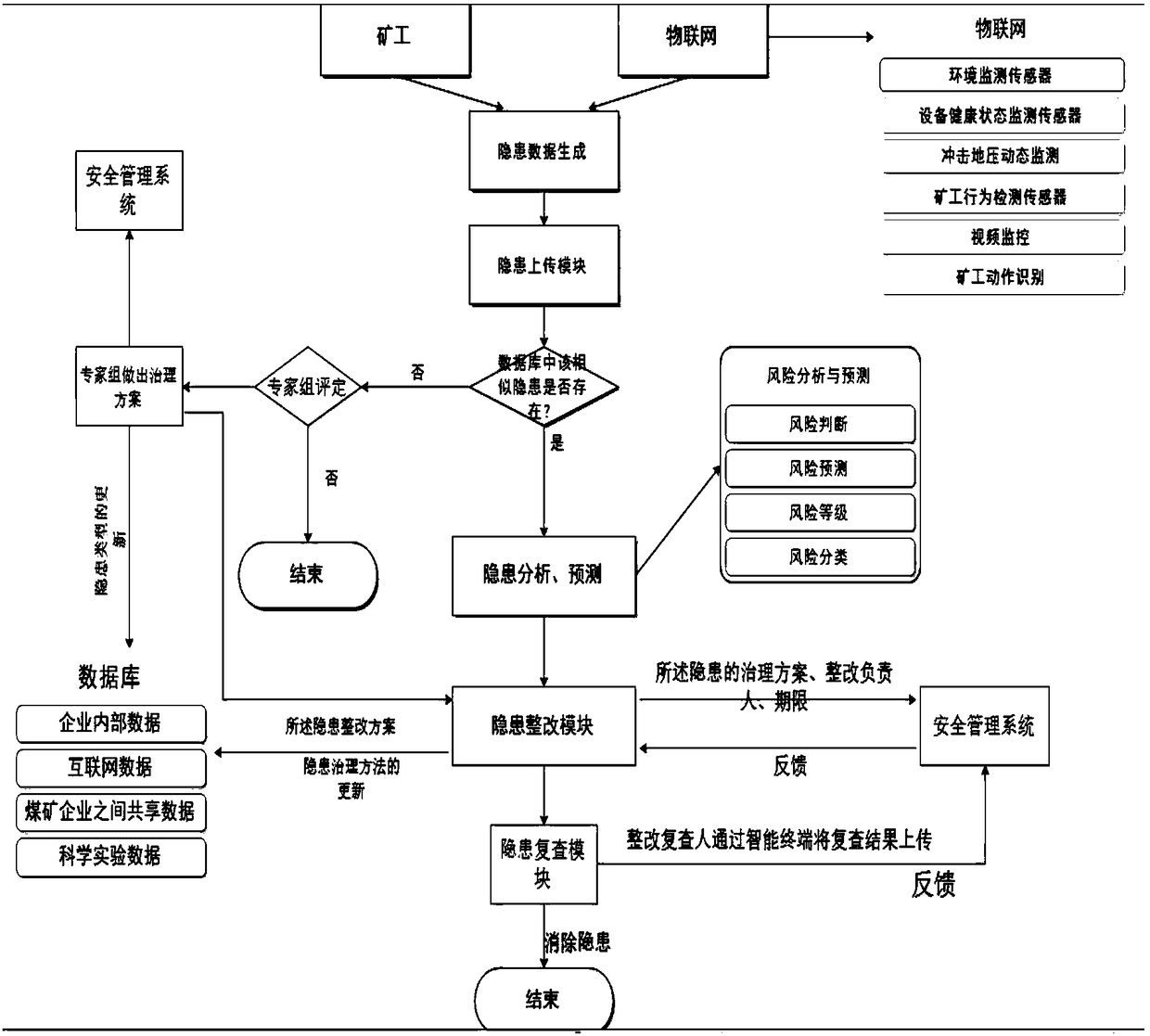

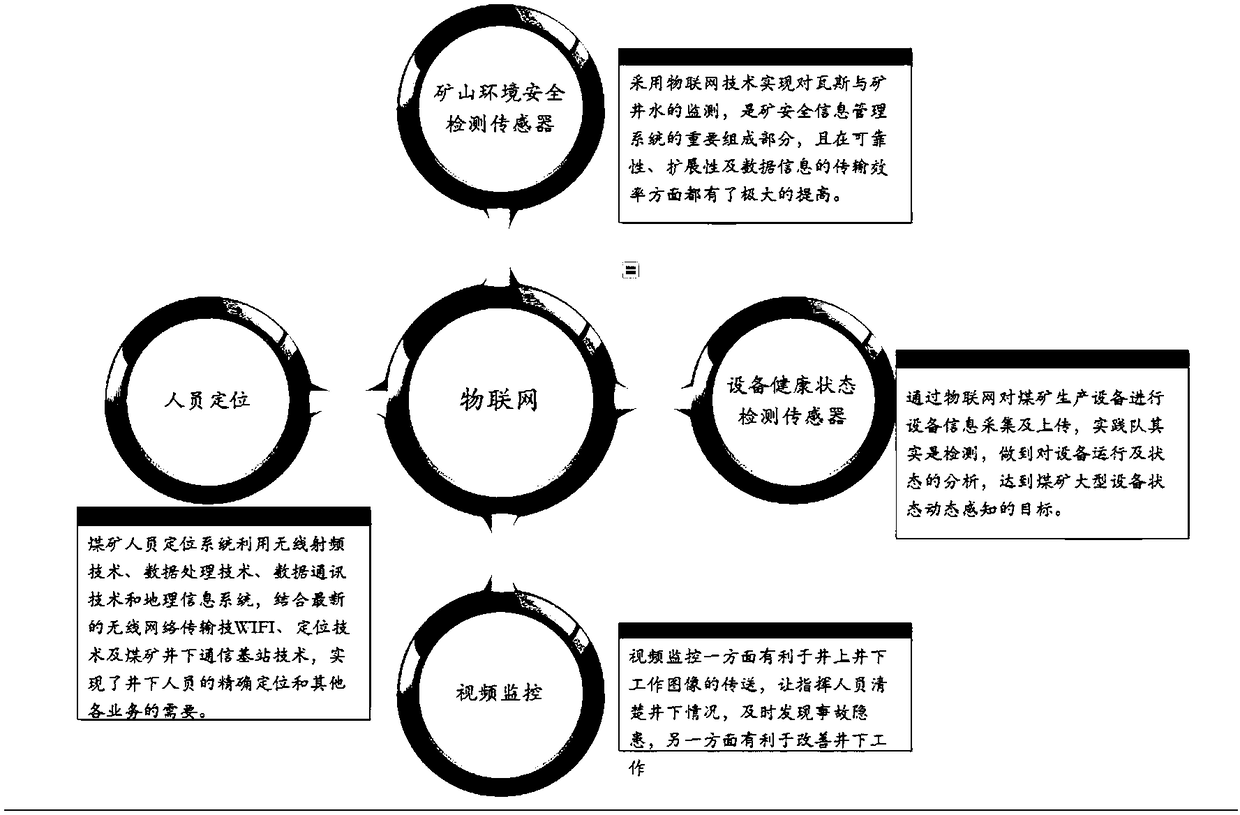

[0026] The present invention aims at the disadvantages of hidden danger investigation and treatment in coal mines, such as insufficient timeliness and comprehensiveness of hidden danger investigation, delayed transmission of hidden danger information, untimely implementation of hidden danger treatment plan, inadequate supervision of hidden danger treatment progress and poor management, etc., and provides a material-based Networking, big data coal mine safety production hidden danger closed-loop management system. It is characterized in that it includes: a hidden danger collection module, which is used to collect coal mine safety hidden danger information; a hidden danger upload module, which is used to upload safety production hidden danger information; a hidden danger processing module, which is used to classify and grade the entered hidden dangers and give a treatment plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com