Screening electric precipitator

An electrostatic precipitator and screening technology, which is applied in the direction of external electrostatic separator, electrode structure, power supply technology, etc., can solve the problem of obvious dust caused by secondary dust in the precipitator, avoid rapping secondary dust, and improve the driving speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

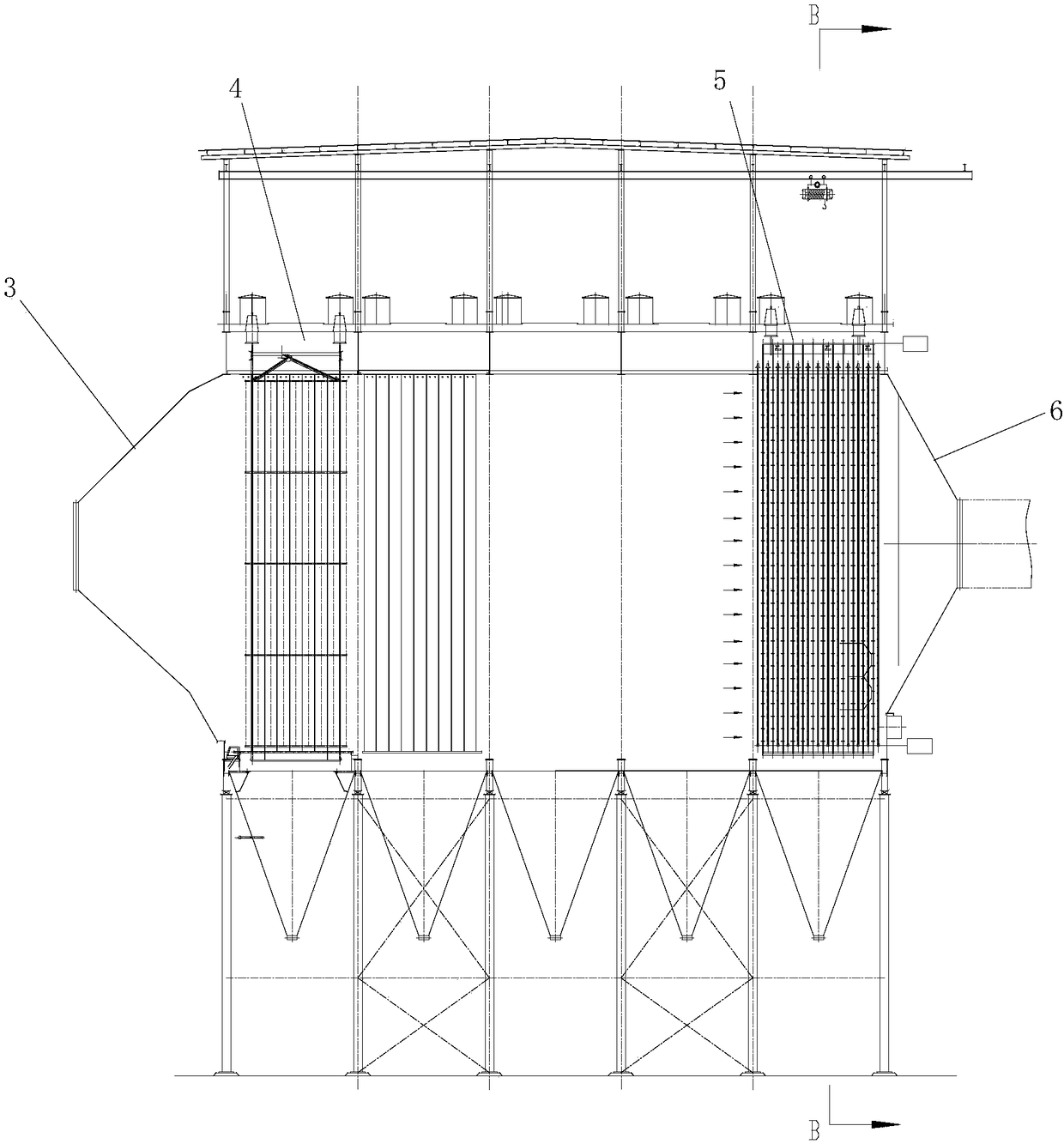

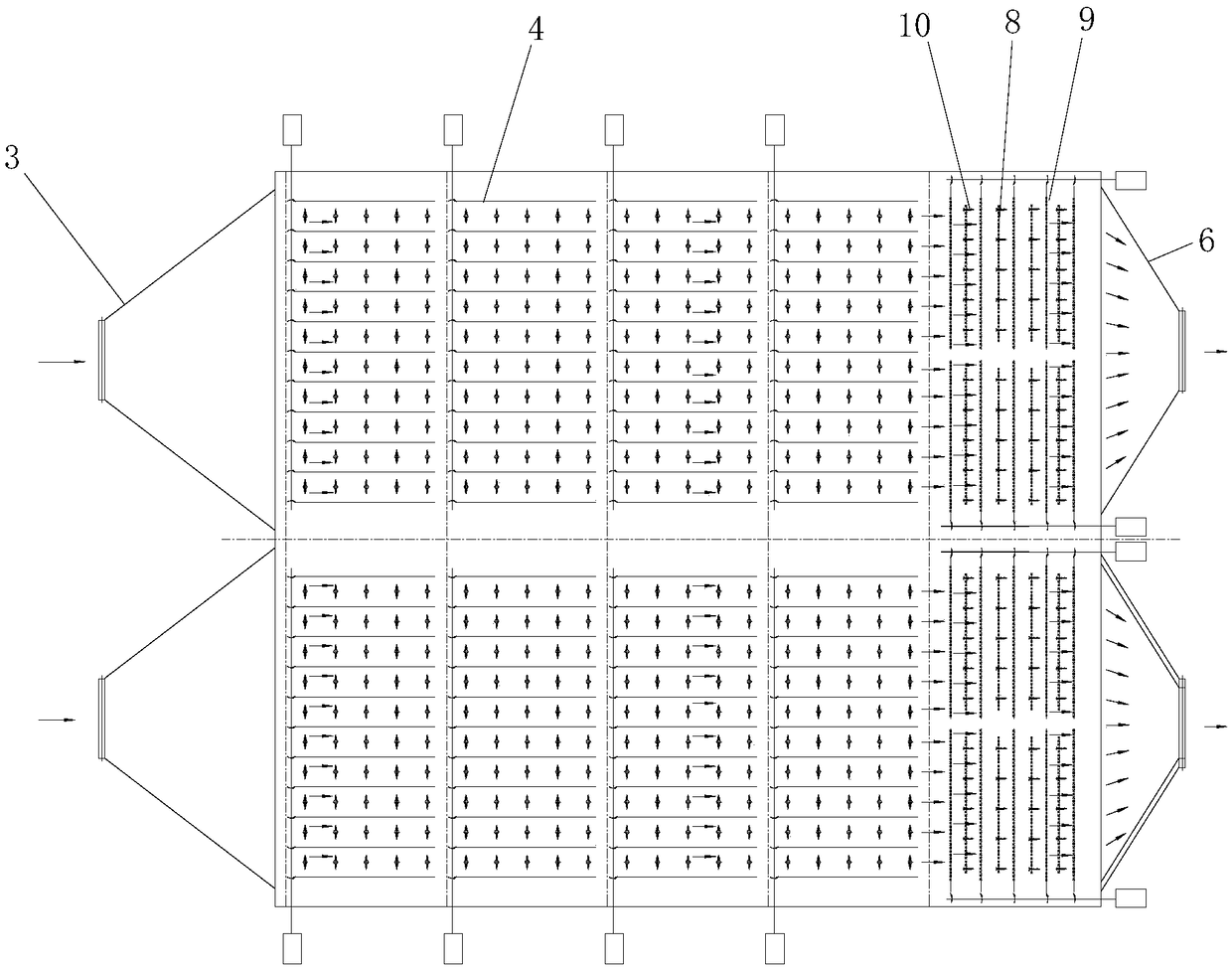

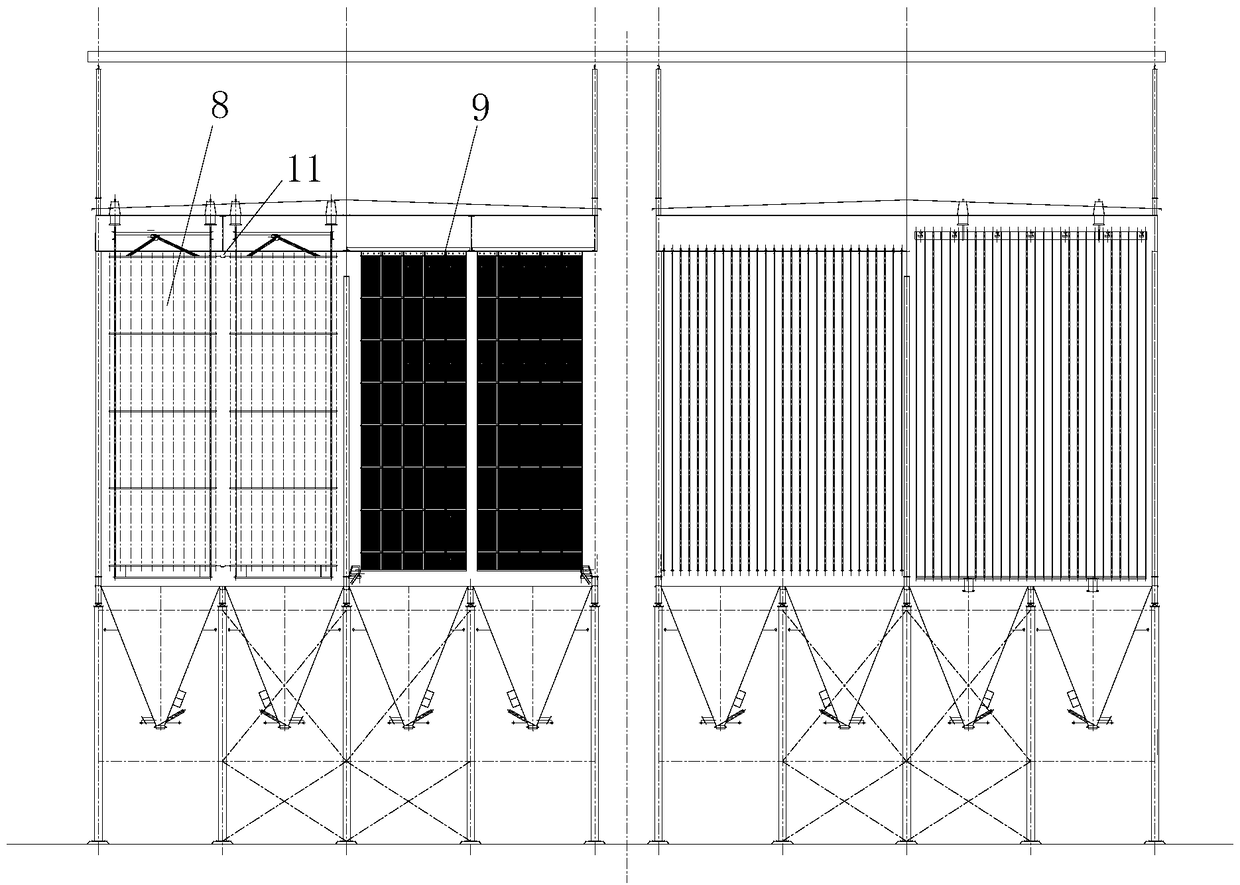

[0018] refer to figure 1 , figure 2 , image 3 It is an embodiment of a screening electrostatic precipitator of the present invention, a screening electrostatic precipitator, which sequentially includes an inlet horn 3, a conventional electric field 4, a screening electric field 5 and an outlet horn 6 along the flue gas flow direction, and the screening electric field 5 Including the cathode part 8 and the anode part 9, both of the cathode part 8 and the anode part 9 are steel wire mesh, which are called the cathode steel wire mesh and the anode steel wire mesh in order to distinguish them, but their basic structure is the same as that of the anode plate and the smoke of the conventional electrostatic precipitator. The gas parallel arrangement is different. The steel wire mesh of the cathode part 8 and the anode part 9 of the device is perpendicular to the flow direction of the flue gas. The flue gas needs to pass through the small holes of the steel mesh. Steel wire mesh i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com