Workpiece bearing device for glue dispenser and glue dispenser

A technology of a carrying device and a glue dispenser, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of a large area of the double station glue dispenser, improve the dispensing efficiency, shorten the time, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

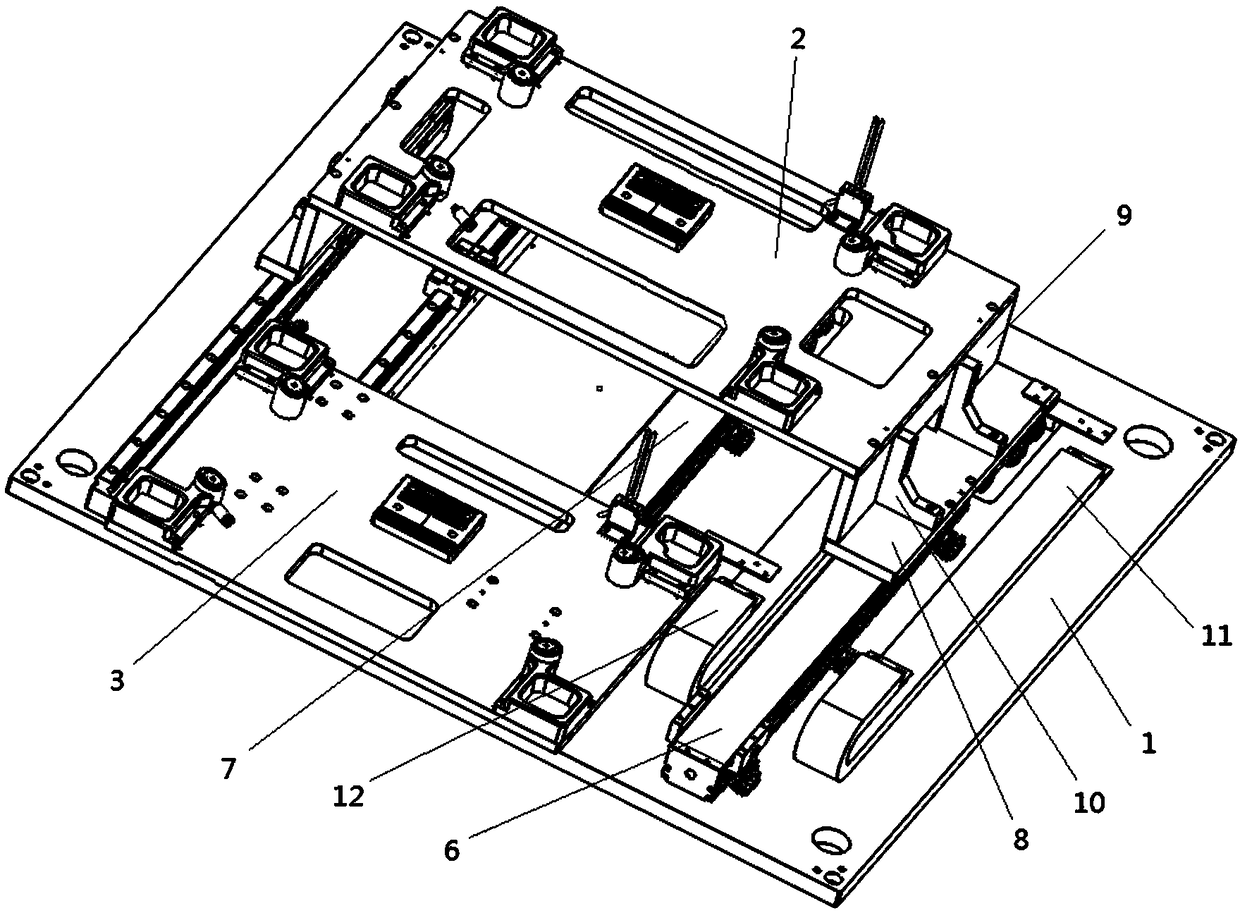

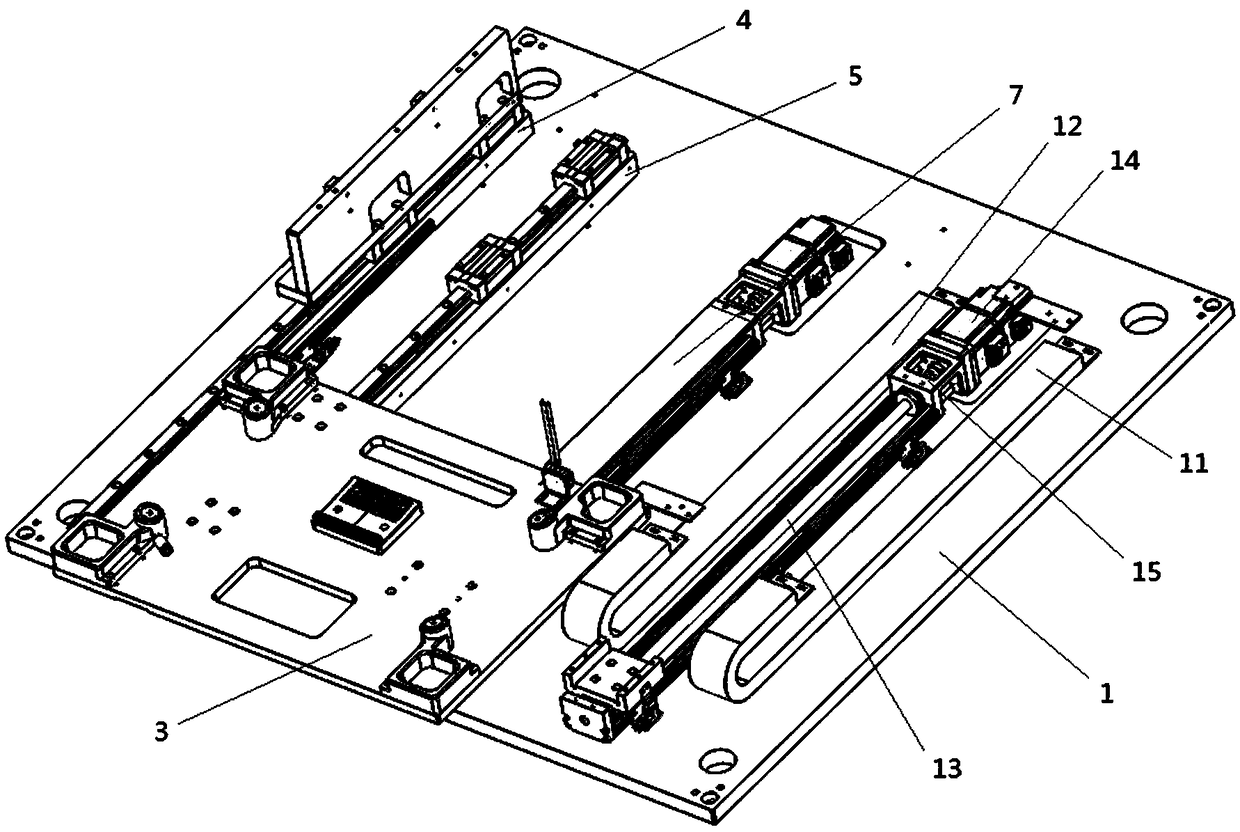

[0050] Such as figure 1 and figure 2 As shown, this embodiment provides a workpiece carrying device for a glue dispenser, which includes a workbench 1, a stage assembly, at least two guiding mechanisms, at least two driving mechanisms, and a connecting plate 8 , side panels 9, ribs 10 and towline components.

[0051] The stage assembly is arranged on the workbench 1, and includes at least two stages arranged at intervals along the direction perpendicular to the workbench 1, the stage is suitable for carrying workpieces to be dispensed, and has a The inside of the workbench 1 is suitable for the dispensing position of dispensing, and the outside of the workbench 1 is suitable for the loading and unloading position of the workpiece to be dispensed, and when at least one of the carriers is located at the dispensing position , at least one other carrier is located at the loading and unloading position, that is, at least two running trajectories corresponding to at least two car...

Embodiment 2

[0067] The present embodiment provides a kind of dispensing machine, and described dispensing machine comprises the workpiece carrying device of the dispensing machine described in embodiment 1, and dispensing needle (not shown in figure), driving assembly (not shown in figure) and control system; the dispensing needle is used for dispensing the workpiece to be dispensed; the drive assembly is used to drive the dispensing needle to move according to a predetermined trajectory; the control system communicates with the drive assembly and the power device signal respectively connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com