A Method for Improving the Bottom Scouring of Vacuum Induction Melting Ingot Mold

A technology of vacuum induction smelting and steel ingot mould, which is applied in ingot workshops, casting molten material containers, process efficiency improvement, etc., can solve problems such as high cost, deterioration of steel ingot purity, and difficult supply, and achieve the goal of prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

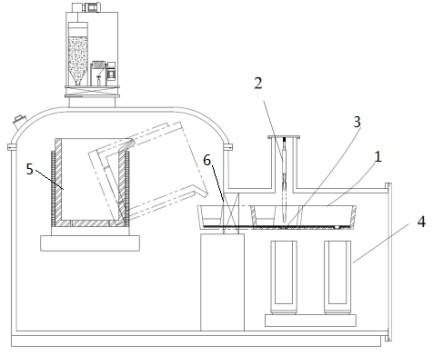

[0014] refer to figure 1 , 2 And 3, vacuum induction melting and casting of superalloy GH4169, including the following steps:

[0015] Step 1: Use gas or natural gas to bake the L-shaped tundish, put the baked L-shaped tundish 1 into the casting chamber, and start vacuuming, turn on the heating switch of the L-shaped tundish 1 to start heating. After the vacuum degree of the casting chamber is the same as that of the melting chamber, the vacuum isolation valve 6 is opened, and the L-shaped tundish 1 is moved to the pouring position. Lower the stopper device 2 to the gate. The maximum superheat of the molten pool is controlled at Tm+30°C.

[0016] Step 2: Tilt the crucible 1 to start pouring. When the solution in the L-shaped tundish 1 reaches two-thirds of the height, lift the stopper rod by 3mm, so that the high-temperature GH4169 melt flows into the spiral nozzle 3 at a low flow rate and low flow rate, and passes through the spiral nozzle. The nozzle 3 changes the vertic...

Embodiment 2

[0018] refer to figure 1 , 2 And 3, vacuum induction melting and casting of superalloy GH4169, including the following steps:

[0019] Step 1: Use gas or natural gas to bake the L-shaped tundish, put the baked L-shaped tundish 1 into the casting chamber, and start vacuuming, turn on the heating switch of the L-shaped tundish 1 to start heating. After the vacuum degree of the casting chamber is the same as that of the melting chamber, the vacuum isolation valve 6 is opened, and the L-shaped tundish 1 is moved to the pouring position. Lower the stopper device 2 to the gate. The maximum superheat of the molten pool is controlled at Tm+50°C.

[0020] Step 2: Tilt the crucible 1 to start pouring. When the solution in the L-shaped tundish 1 reaches two-thirds of the height, lift the stopper rod by 5mm, so that the high-temperature GH4169 melt flows into the spiral nozzle 3 at a low flow rate and low flow rate, and passes through the spiral nozzle. The nozzle 3 changes the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com