Locating element for accurately machining plunger helix

A plunger screw and positioning element technology, which is applied in the direction of grinding workpiece supports, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven axial force, inconsistent cutting removal amount, low production efficiency, etc., and achieve geometric Improvement of accuracy, consistency of high quality, and reduction of processing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

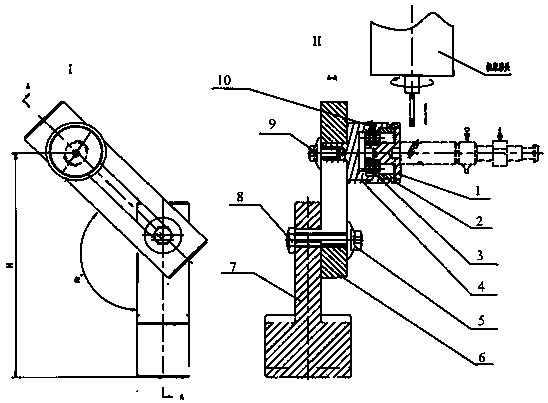

[0033] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

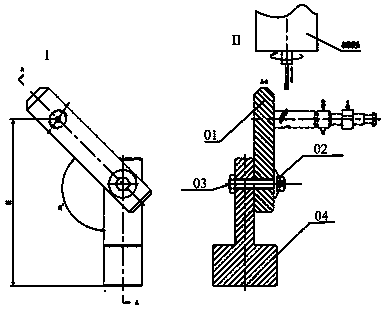

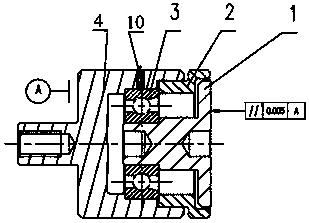

[0034] refer to Figure 3 to Figure 8 As shown, the positioning element of this embodiment is an assembled and combined structure, including: a workbench base 7, a frame plate 6 and a positioning unit, the frame plate 6 is vertically installed on the workbench base 7, and the positioning unit is vertically installed on the frame plate 6 Above, the positioning unit is provided with a positioning block 1. When working, the end face of the positioning block 1 presses against the end face of the top of the plunger to perform axial positioning.

[0035] Wherein, the workbench base 7 and the frame plate 6 are connected and locked by the nut 8 and the first bolt 5 ; the frame plate 6 and the positioning unit are connected and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com