Composite board and preparation method thereof, shell and electronic equipment

A technology for composite sheets and electronic equipment, applied in the field of materials, can solve the problems that the hardness and scratch resistance of the composite sheet cannot meet the requirements, the electronic equipment is easily broken or scratched, and the consumer experience cannot be satisfied, and the hardness can be improved. and the effects of scratch resistance, high densification, best hardness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

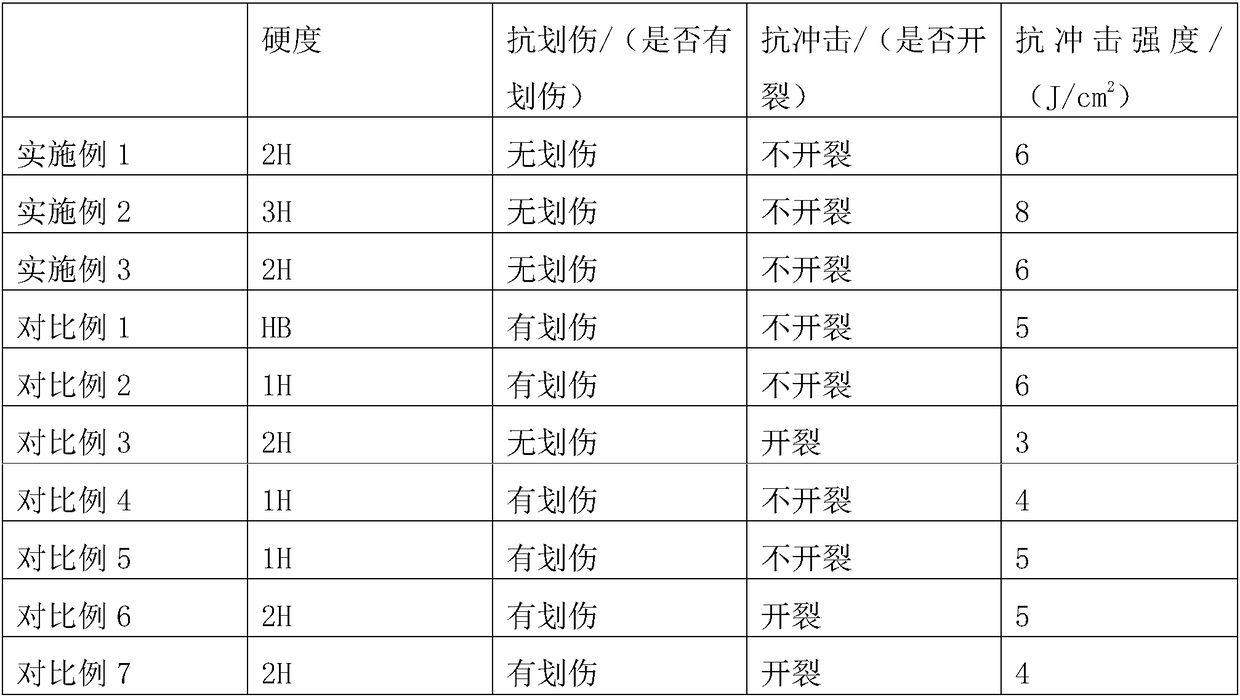

Embodiment 1

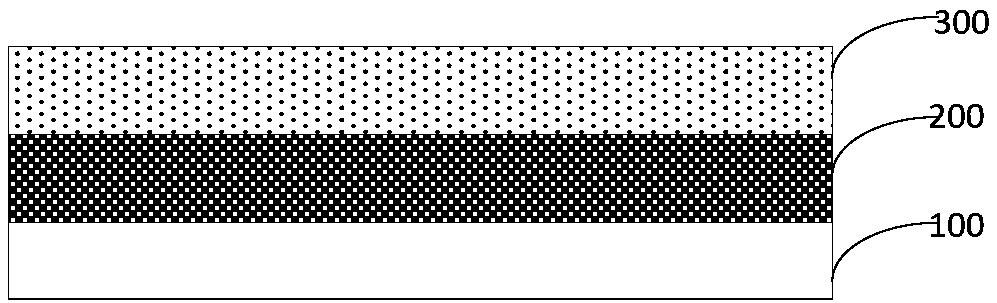

[0066] Composite panels include:

[0067] Impact-resistant layer: the forming material is PC (impact resistance is 6J), and the thickness is 0.4mm;

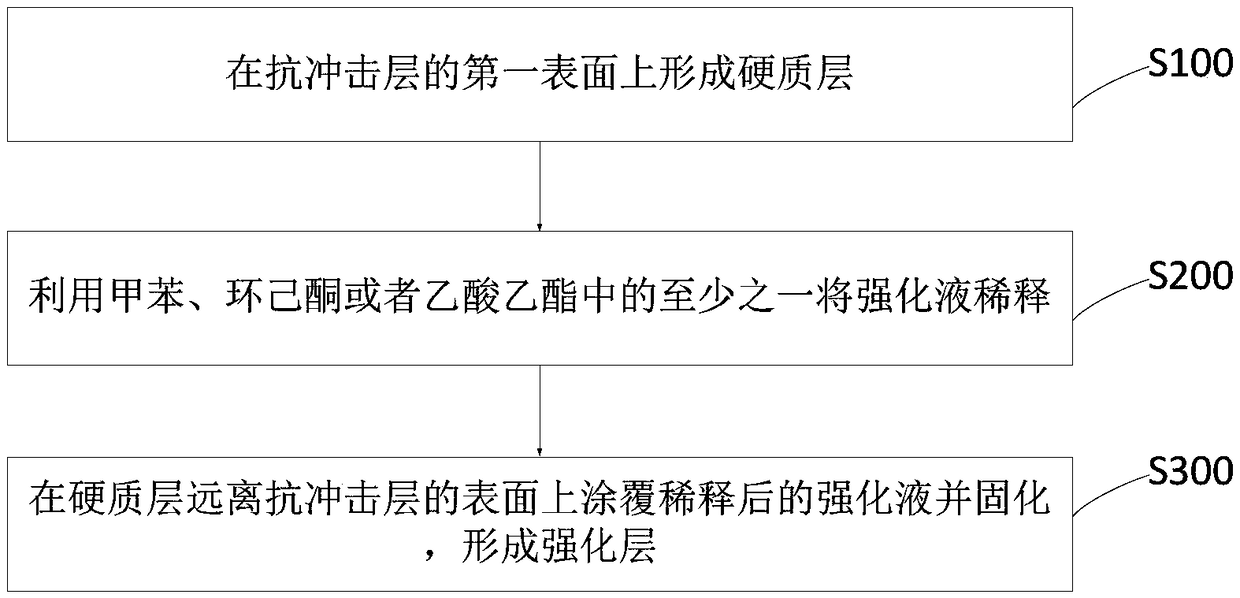

[0068] Hard layer: the forming material is PET (hardness 2H), and the thickness is 0.1mm;

[0069] Reinforcing layer: the thickness is 0.01mm, and the strengthening liquid forming the reinforcing layer includes 25 parts by weight of acrylic resin, 0.3 parts by weight of silicone resin, 24 parts by weight of hydroxy ketones, 6 parts by weight of acyl phosphine oxide, and 0.4 parts by weight of isopropanol, 1.6 parts by weight of propylene glycol methyl ether, 11.3 parts by weight of silicon dioxide dispersion, 0.3 parts by weight of leveling agent, wherein, the strengthening solution before dilution / diluted strengthening solution=25wt%, and the curing energy is 350MJ / cm 2 .

Embodiment 2

[0071] Composite panels include:

[0072] Impact-resistant layer: the forming material is high-toughness PC (impact strength is 8J), and the thickness is 0.6mm;

[0073] Hard layer: the forming material is high-hardness PET (hardness 3H), and the thickness is 0.2mm;

[0074] Reinforcing layer: the thickness is 0.05mm, and the strengthening liquid forming the reinforcing layer includes 55 parts by weight of acrylic resin, 0.5 parts by weight of silicone resin, 44 parts by weight of hydroxy ketones, 16 parts by weight of acyl phosphine oxide, and 0.6 parts by weight of isopropanol, 1.8 parts by weight of propylene glycol methyl ether, 25.3 parts by weight of silicon dioxide dispersion liquid, 0.5 parts by weight of leveling agent, wherein, strengthening liquid before dilution / diluted strengthening liquid=35wt%, curing energy is 410MJ / cm 2 .

Embodiment 3

[0076] Composite panels include:

[0077] Impact-resistant layer: the forming material is PC, the thickness is 0.5mm;

[0078] Hard layer: the forming material is PET, the thickness is 0.15mm;

[0079] Reinforcing layer: the thickness is 0.03mm, and the strengthening liquid forming the reinforcing layer includes 35 parts by weight of acrylic resin, 0.4 parts by weight of silicone resin, 34 parts by weight of hydroxy ketones, 10 parts by weight of acyl phosphine oxide, 0.5 parts by weight of isopropanol, 1.7 parts by weight of propylene glycol methyl ether, 0.4 parts by weight of leveling agent, wherein, strengthening liquid before dilution / diluted strengthening liquid=30wt%, curing energy is 380MJ / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com