Packaging process for gear

A packaging technology and gear technology, which is applied in the field of gear processing, can solve the problems of affecting gear processing efficiency, gear production efficiency, and adhesion on gears, so as to improve speed and precision, prevent slipping, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

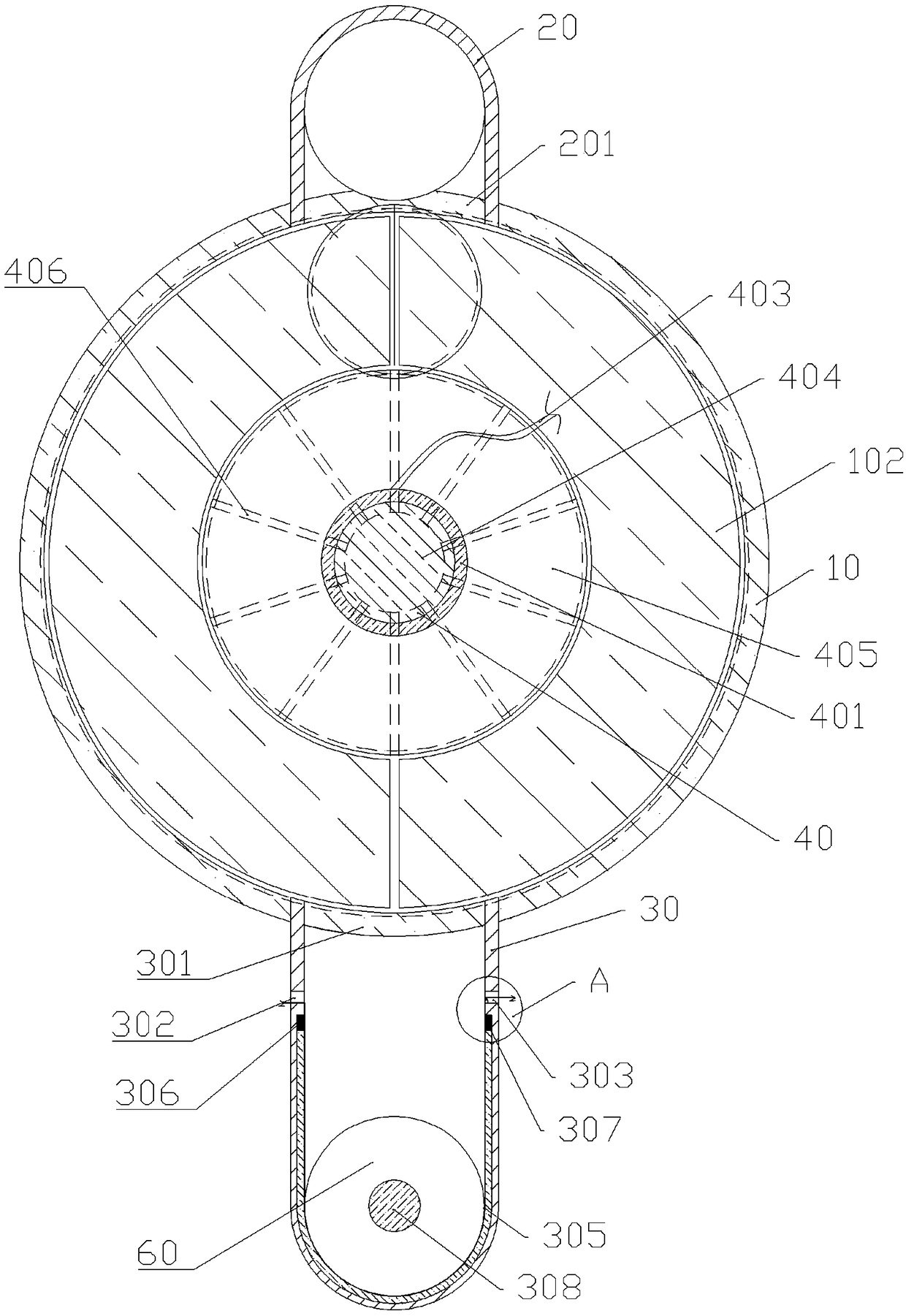

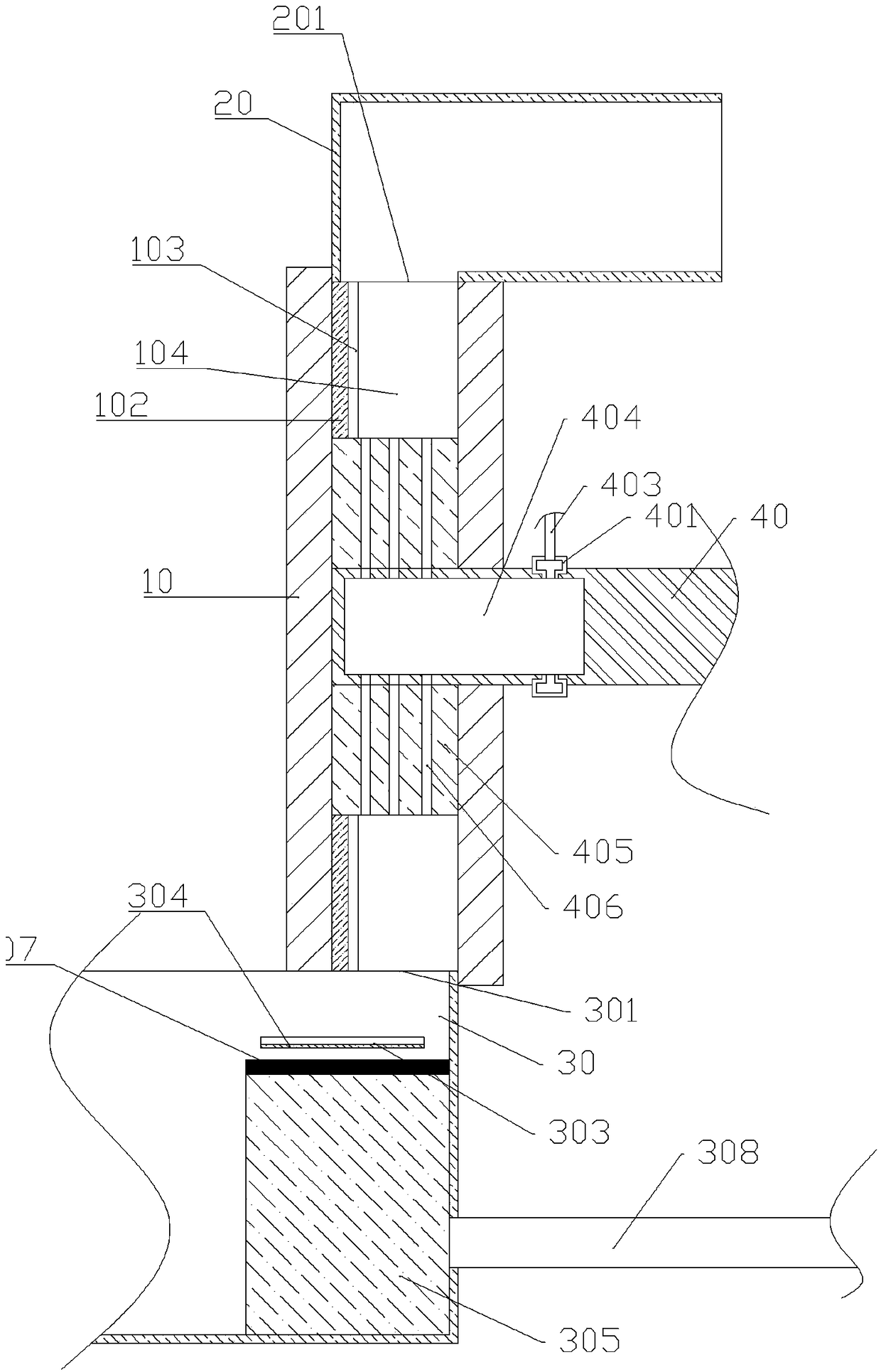

[0023] The reference numerals in the accompanying drawings of the description include: delivery box 10, cleaning cotton 102, installation port 103, delivery cavity 104, second delivery cylinder 20, discharge port 201, first delivery cylinder 30, feed inlet 301, first Through hole 302, second through hole 303, sawtooth 304, buffer plate 305, first electromagnet 306, second electromagnet 307, push rod 308, rotating shaft 40, fixing ring 401, air intake pipe 403, air intake cavity 404, transmission Wheel 405, runner 406, air outlet 407, packing material 50, gear 60.

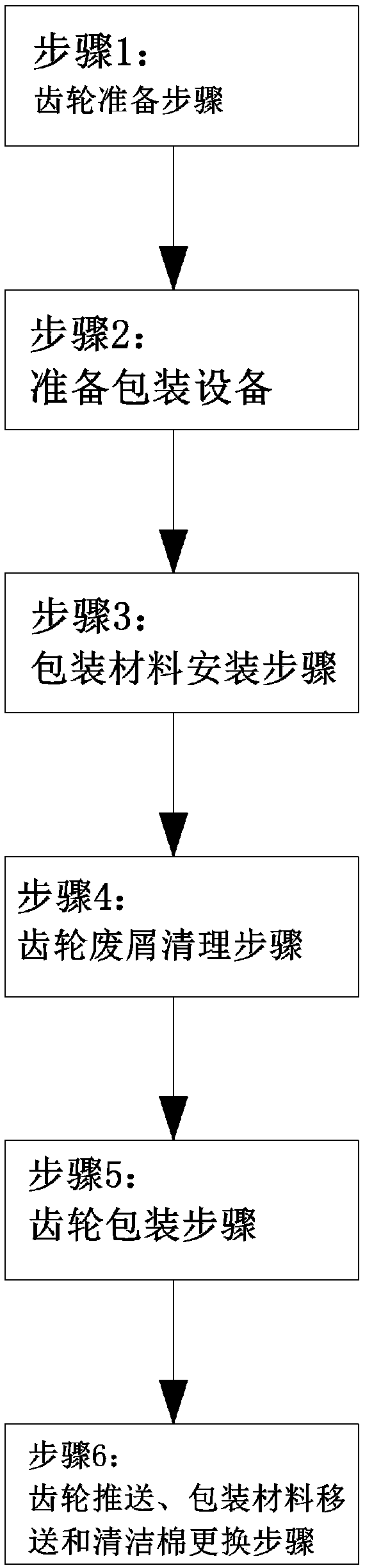

[0024] The operating steps of the packaging process for gears in the present embodiment are basically as attached figure 1 As shown, the specific steps are as follows:

[0025] Step 1: Prepare packing materials and several gears to be packed.

[0026] Step 2: Prepare a basic as attached figure 2 , attached image 3 , attached F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com