Improved Orbal oxidation ditch

An Aubert oxidation ditch, an improved technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as small room for adjustment, sludge sedimentation, and limited oxidation ditch depth , to achieve the effect of reliable structure and increased water depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

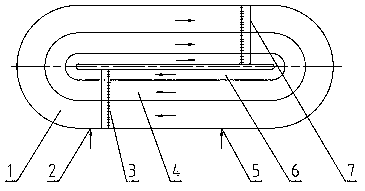

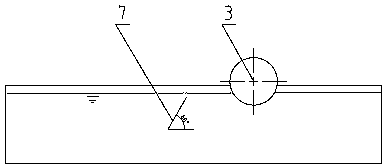

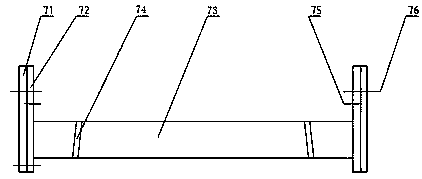

[0024] Such as figure 1 and figure 2 As shown, an improved Aubert oxidation ditch of the embodiment of the present invention includes an anaerobic tank 1, anoxic tank 4 and aerobic tank 6 arranged sequentially from outside to inside. The outer wall of the anaerobic tank 1 is provided with a sewage inlet 5 and a return sludge outlet 2 . The oxidation ditch also includes an aerator 3 and an adjustable diversion device 7 . The aerator 3 is assembled on the straight road of each pond. The adjustable flow guide device 7 is located downstream of the aerator 3, and the adjustable flow guide device 7 is assembled on the straight path of each pond.

[0025] In the Auber oxidation ditch of above-mentioned embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com