Pervious concrete and preparation method thereof

A technology of permeable concrete and cement, applied in the field of concrete, can solve the problems of complicated preparation methods of large logarithmic permeable concrete, unfavorable practical application, etc., and achieve the effects of unique artistry and ornamental, rich colors, and purifying the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

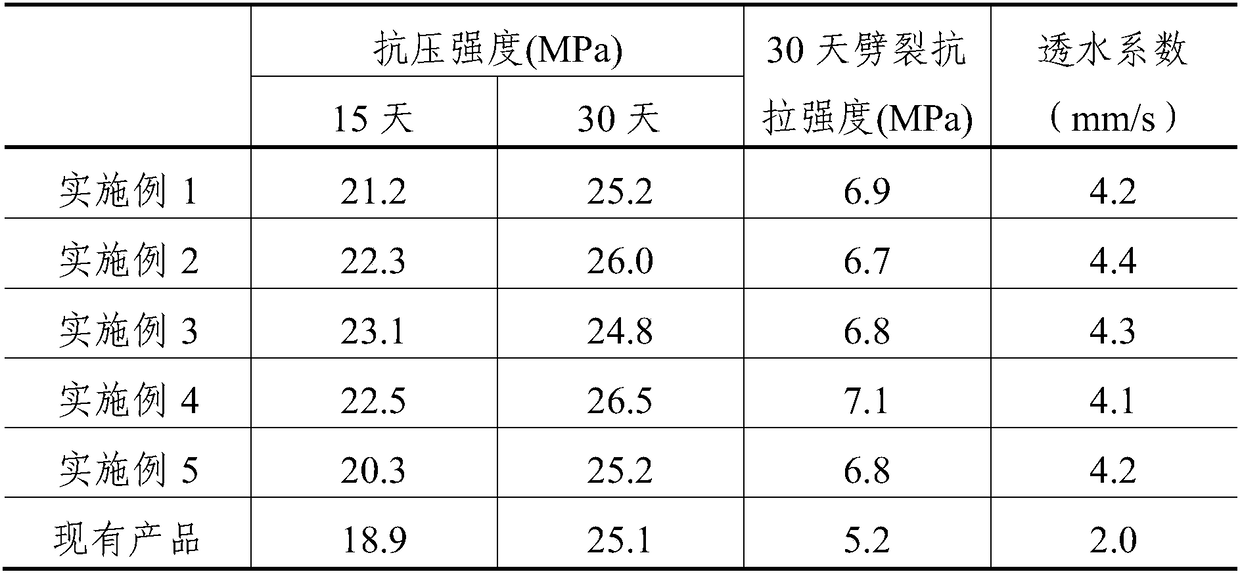

Examples

Embodiment 1

[0023] The preparation method of the permeable concrete of the present embodiment is prepared according to the following steps:

[0024] Step 1. Stir 0.3 parts of polycarboxylate high-performance water reducer and 2.7 parts of water for 15 minutes to mix thoroughly, and spray evenly on the surface of 38 parts of single-grain gravel with a particle size of 20mm in layers to prepare mixed aggregate (based on bone It is advisable that the surface of the material is fully wet without water droplets flowing out);

[0025] Step 2, 10 parts of 42.5 grade ordinary Portland cement, 1.2 parts of biochar and 1.2 parts of coloring agent were stirred for 40 minutes and fully mixed to prepare the mixture;

[0026] Step 3: Stir the mixing agent and the mixed aggregate fully to obtain permeable concrete (it is better to use the slurry to cover the aggregate evenly and fully without flowing down the slurry).

[0027] Step 4: heat-preserve, moisturize, and cover the permeable concrete after co...

Embodiment 2

[0029] The preparation method of the permeable concrete of the present embodiment is prepared according to the following steps:

[0030] Step 1. Stir 0.5 parts of polycarboxylate high-performance water reducer and 2 parts of water for 18 minutes to mix thoroughly, and spray evenly on the surface of 35 parts of single-grain gravel with a particle size of 5mm in layers to prepare mixed aggregate (based on bone It is advisable that the surface of the material is fully wet without water droplets flowing out);

[0031] Step 2, 8 parts of 42.5 grade ordinary Portland cement, 1.1 parts of biochar and 1.5 parts of coloring agent were stirred for 30 minutes and fully mixed to prepare the mixture;

[0032] Step 3: Stir the mixing agent and the mixed aggregate fully to obtain permeable concrete (it is better to use the slurry to cover the aggregate evenly and fully without flowing down the slurry).

[0033] Step 4: heat-preserve, moisturize, and cover the permeable concrete after constr...

Embodiment 3

[0035] The preparation method of the permeable concrete of the present embodiment is prepared according to the following steps:

[0036] Step 1. Stir 0.1 part of polycarboxylate high-performance water reducer and 3 parts of water for 10 minutes to mix thoroughly, and spray evenly on the surface of 45 parts of single-grain gravel with a particle size of 8 mm to prepare mixed aggregate (based on bone It is advisable that the surface of the material is fully wet without water droplets flowing out);

[0037] Step 2, 15 parts of 42.5 grade ordinary Portland cement, 0.8 parts of biochar and 1.3 parts of coloring agent were stirred for 36 minutes and fully mixed to prepare the mixture;

[0038] Step 3: Stir the mixing agent and the mixed aggregate fully to obtain permeable concrete (it is better to use the slurry to cover the aggregate evenly and fully without flowing down the slurry).

[0039] Step 4: heat-preserve, moisturize, and cover the permeable concrete after construction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com