Inorganic nanomaterial printing ink and preparation method thereof

A technology of inorganic nanomaterials and printing inks, applied in printing, inks, household appliances, etc., can solve problems such as difficulty in taking into account viscosity, boiling point and dispersion effect, and achieve the effects of easy standardized control, lower threshold voltage, and improved energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] And, the embodiment of the present invention also provides a method for preparing an inorganic nanomaterial thin film, comprising the following steps:

[0044] S01. Weigh each component according to the formula of the above-mentioned inorganic nanomaterial printing ink;

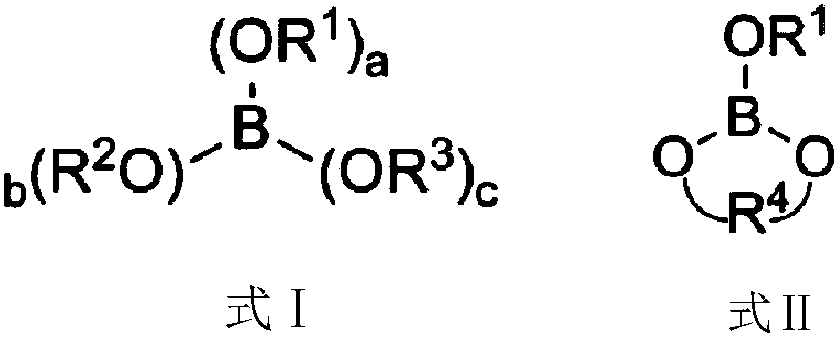

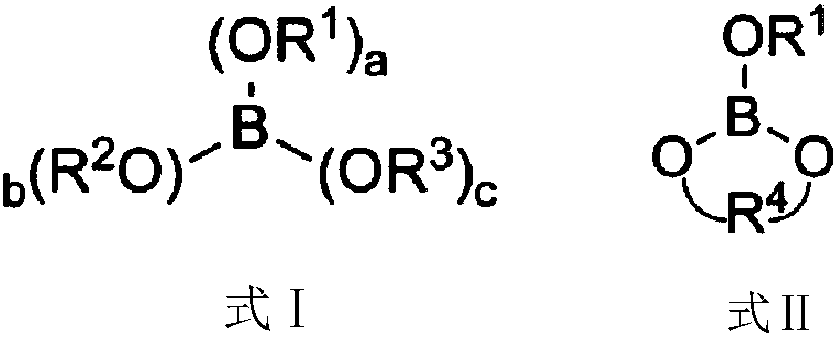

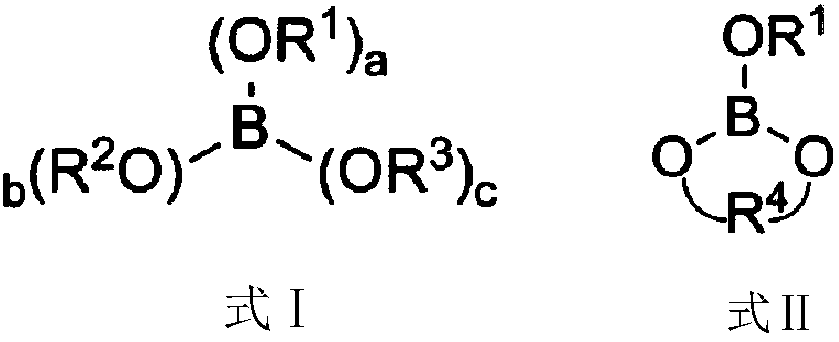

[0045] S02. Dissolving inorganic nanomaterials in an organic solvent to form an inorganic nanomaterial printing ink, wherein the organic solvent contains at least one boric acid ester organic solvent;

[0046] S03. Inkjet printing is used to deposit inorganic nano-printing ink on the carrier, and after drying, an inorganic nano-material thin film is obtained.

[0047] Specifically, in the above step S01, the formulation of the inorganic nanomaterial printing ink and its preferred components and contents have been stated above, and will not be repeated here to save space.

[0048] In the above step S02, the inorganic nanomaterials are dissolved in the organic solvent, and the dispersion form is not lim...

Embodiment 1

[0054] An inorganic nano-material printing ink, based on the weight percentage of the inorganic nano-material printing ink as 100%, comprises the following components in weight percentage: 10% oleylamine-stabilized blue CdS / CdZnS quantum dots And 90wt% tripentyl borate solvent.

[0055] A method for preparing an inorganic nanomaterial thin film, comprising the following steps:

[0056] S11. Weigh each component according to the above-mentioned formula of inorganic nano-material printing ink; wherein, tripentyl borate is refined to a purity greater than 99.9% by dewatering and deoxygenating by corresponding methods.

[0057] S12. Provide a 500mL single-necked flask, and add oleylamine-stabilized blue CdS / CdZnS quantum dots and tripentyl borate successively while stirring, and stir and mix for 30 minutes to obtain a quantum dot ink composition;

[0058]S13. The quantum dot ink composition is inkjet printed on the carrier by an inkjet printer, and printed into a red quantum dot ...

Embodiment 2

[0060] An inorganic nanomaterial printing ink, based on 100% by weight of the inorganic nanomaterial printing ink, comprises the following components in weight percent: 12% oleylamine-stabilized green CdZnSe / CdZnS and 88% The mixed solvent, in the said mixed solvent, comprises weight percentage and is 50% o-dimethoxybenzene, 38% tri-o-cresyl borate.

[0061] A method for preparing an inorganic nanomaterial thin film, comprising the following steps:

[0062] S21. Weigh each component according to the formula of the above-mentioned inorganic nanomaterial printing ink; wherein, the mixed solvent is composed of o-dimethoxybenzene and tri-o-cresyl borate, and various solvents are refined by dewatering and oxygen removal by corresponding methods To a purity greater than 99.9%.

[0063] S22. Provide a 500mL high-density polyethylene bottle, and in the case of stirring, add oleylamine-stabilized green CdZnSe / CdZnS, o-dimethoxybenzene, and tri-o-cresyl borate in sequence, and stir and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com