Low-temperature L450M pipeline steel and manufacturing method thereof

A pipeline steel and low temperature technology, which is applied in the field of manufacturing L450M steel grade pipeline steel hot-rolled coils for low temperature, can solve the problems of insufficient use of water-substituted alloys, low temperature resistance and high alloy cost, and achieve a good society. The effect of benefit, excellent product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

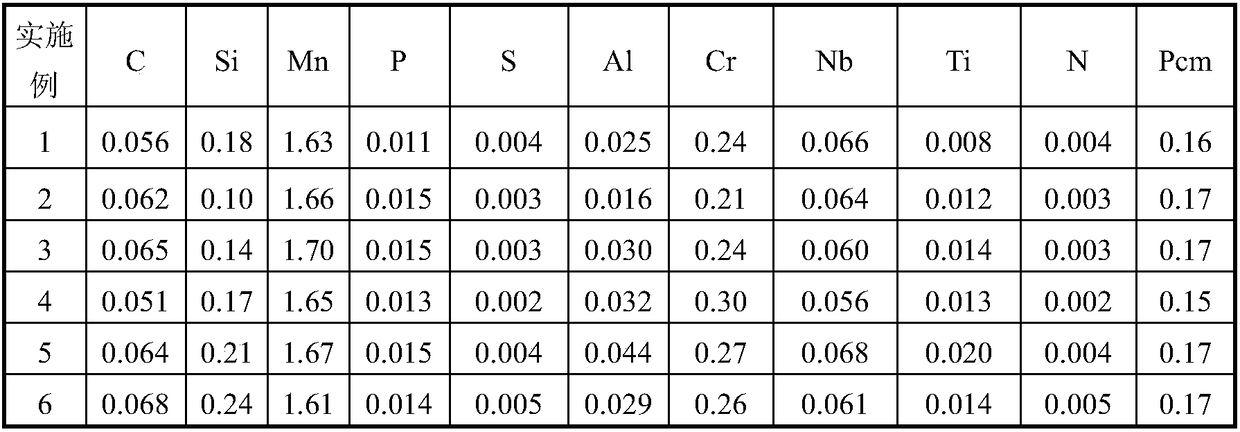

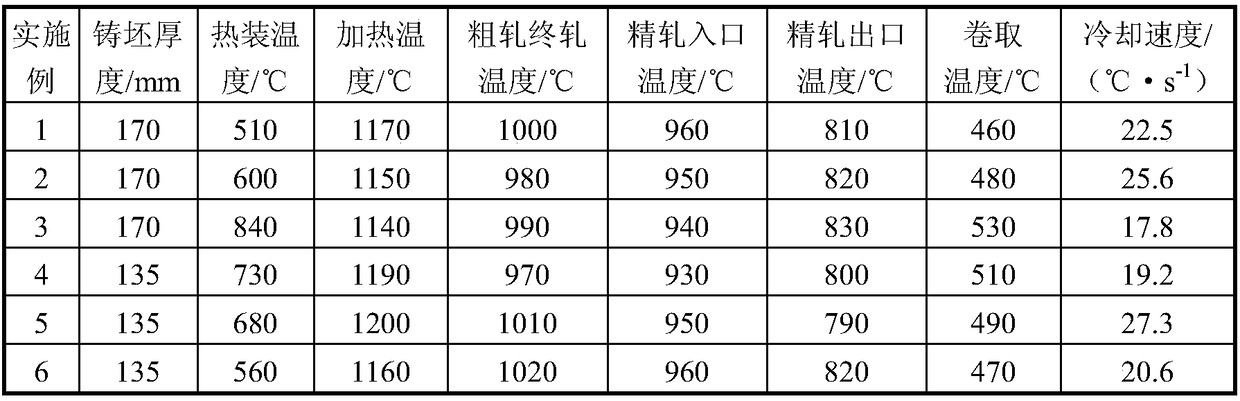

[0037] The technical problems involved in the present invention are solved by the following technical solutions: A low-temperature L450M pipeline steel and its manufacturing method, the mass percentage of its chemical composition is: C 0.050%-0.070%, Si 0.10%-0.25%, Mn 1.61%-1.70 %, Nb 0.056%~0.070%, Cr 0.21%~0.30%, Ti 0.008%~0.020%, Al 0.015%~0.045%, P≤0.020%, S≤0.006%, N≤0.008%, the balance is iron and Unavoidable impurities, and cold crack sensitivity coefficient Pcm≤0.18%. The thickness of the casting slab is less than 200mm. The casting slab is directly heated in the furnace at a temperature of 500-850 ° C, heated to 1140-1200 ° C in a walking heating furnace, and then controlled in two stages of rough rolling and finishing rolling. The rolling temperature is ≥970°C, the finish rolling inlet temperature is ≤970°C, and the finish rolling exit temperature is 790-830°C, and then the steel plate is cooled at a speed of ≥15°C / s by ultra-fast cooling + laminar cooling, at 450-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com