Construction structure and method of steel sheet pile cofferdam with support in deep water

A technology of steel sheet pile cofferdams and steel sheet piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of installation accuracy, difficulty in deep water projects, and slow down construction progress, so as to facilitate decentralized installation and lifting Construction efficiency and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described and illustrated through specific examples below.

[0043] Unless otherwise specified, the raw materials used in the examples of the present invention are commonly used raw materials in the field, and the methods used in the examples are conventional devices and conventional methods in the field.

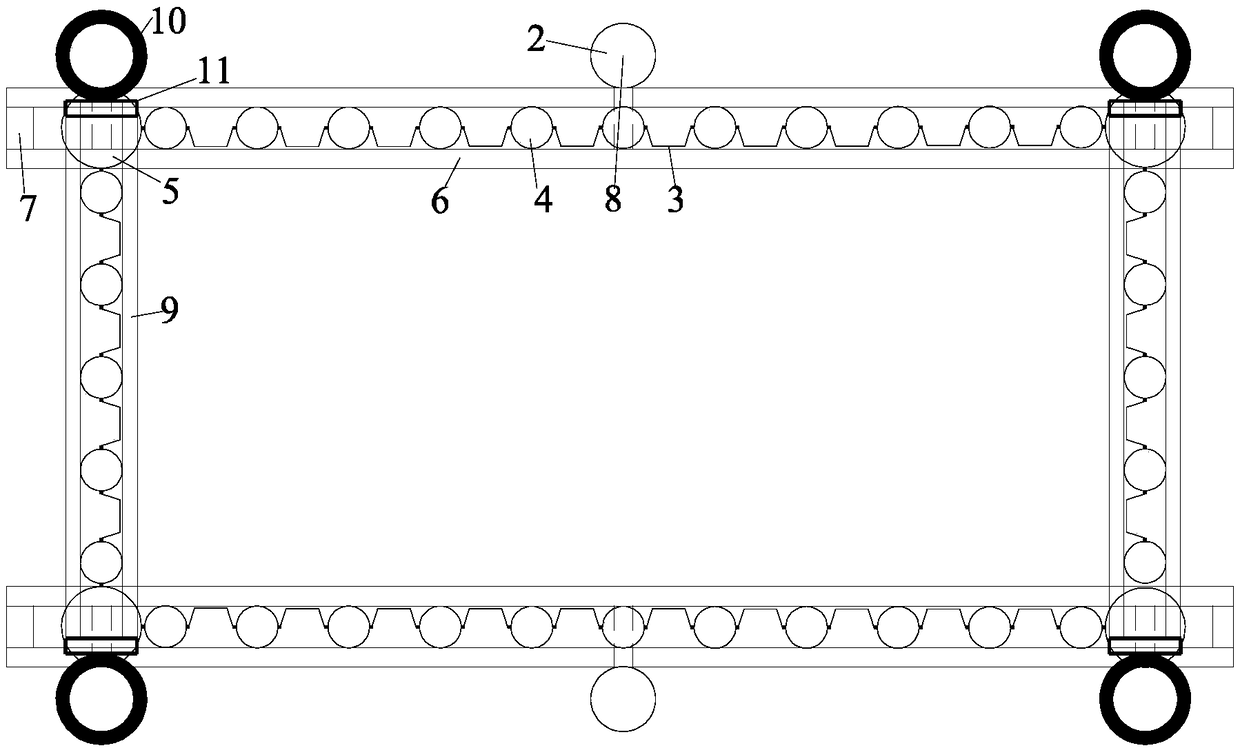

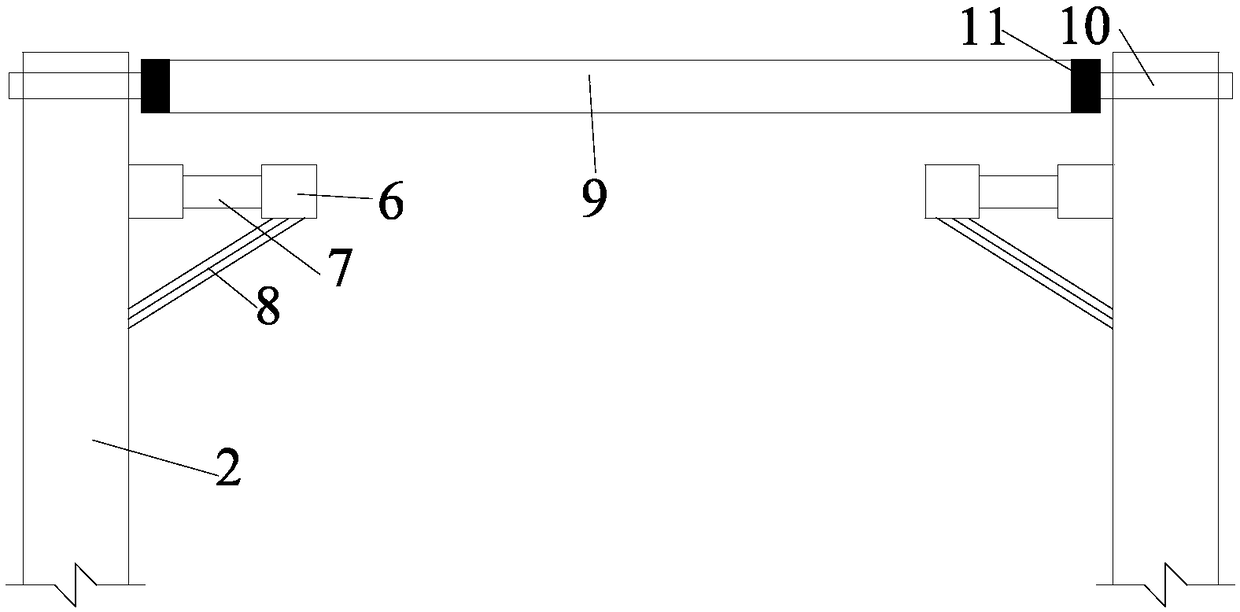

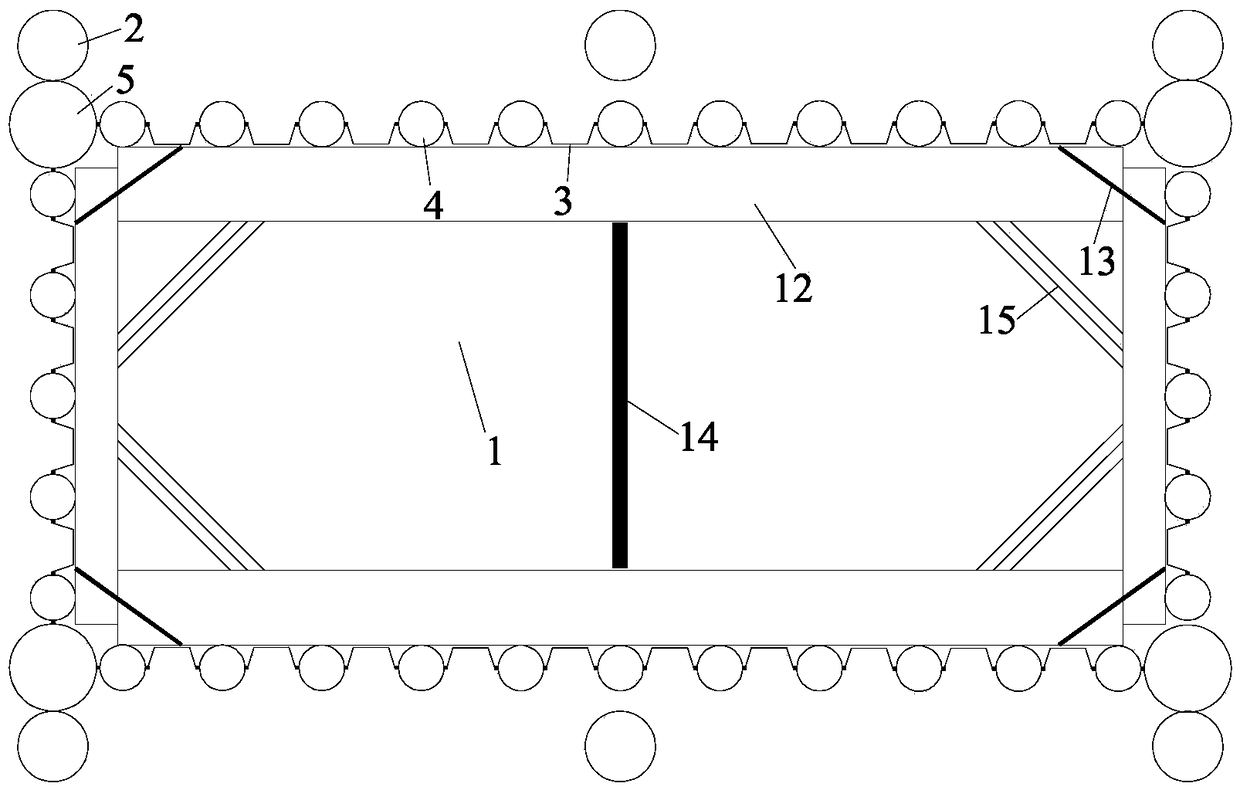

[0044] A deep-water underwater steel sheet pile cofferdam construction structure, including a cofferdam structure, a supporting shelving and fixing system, and an in-situ assembly platform for supporting the water surface; the details are as follows: Figure 1-11 Shown:

[0045]Cofferdam structure, including steel sheet pile 3, pipe pile 4, corner pipe pile 5, purlin 12, purlin cross brace 14, purlin diagonal brace 15, cap 17 and bottom-sealing concrete 18, steel sheet pile 3, pipe pile 4 Staggered connection, the steel sheet pile 3 is a U-shaped structure, the two sides of the steel sheet pile 3 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com