Tank internal pipe line, in particular in fuel tanks of motor vehicles

一种燃料箱、储箱的技术,应用在用于储箱,能够解决制造成本昂贵、损害燃料系统功能、燃料系统损坏等问题,达到简单且制造、便宜制造、突出耐温性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

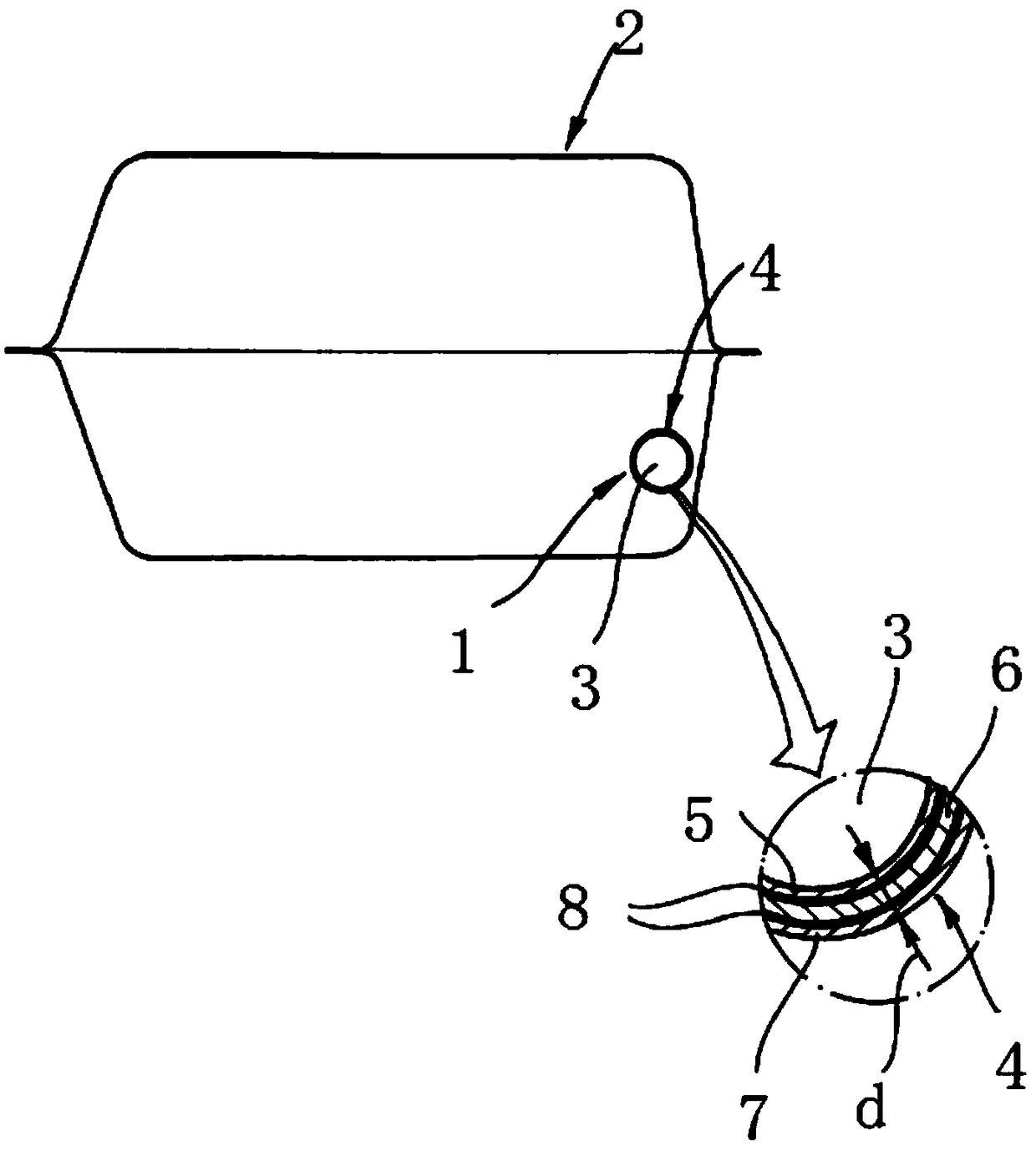

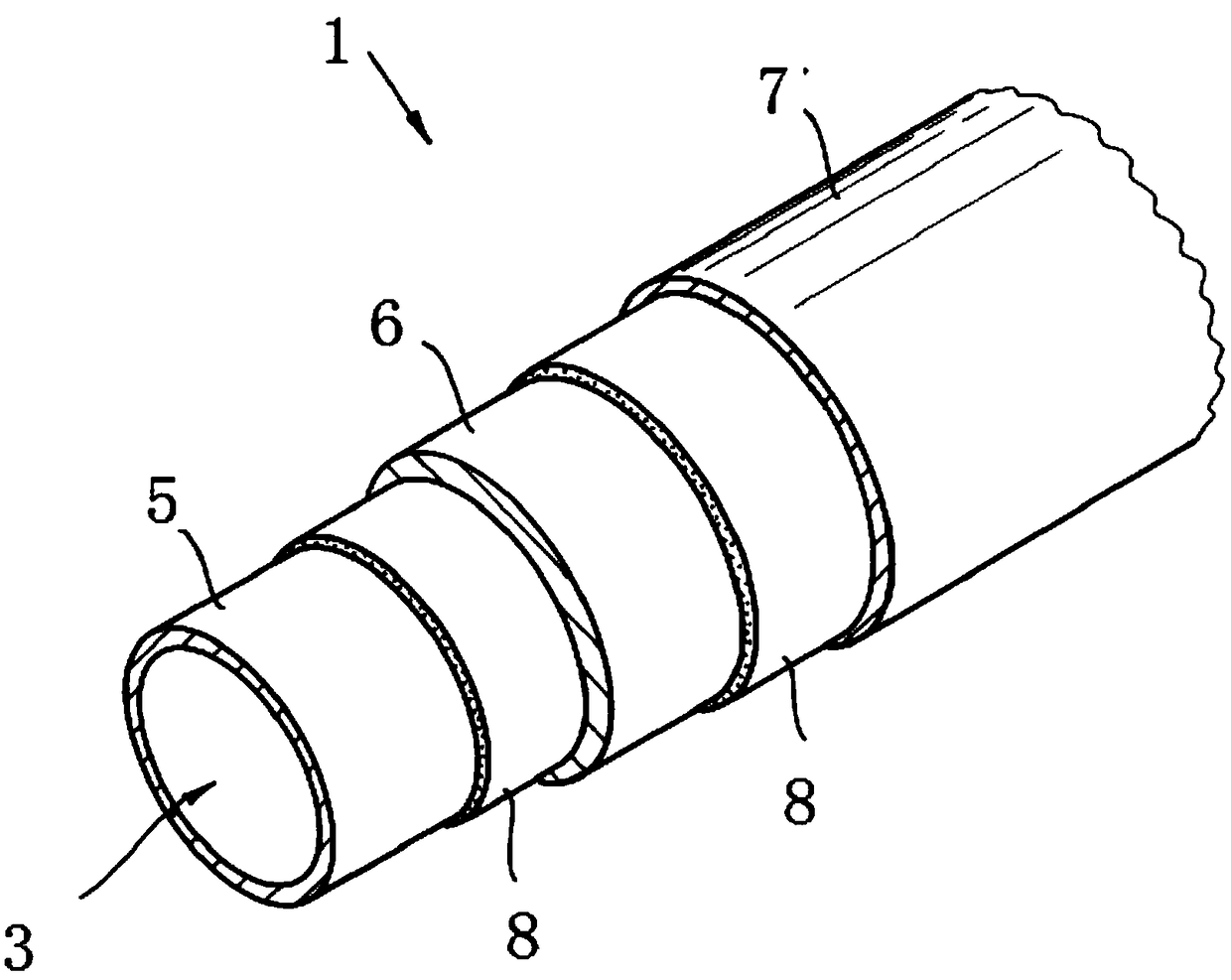

[0028] The figures show an internal conduit 1 for a tank according to the invention, which, as in the exemplary embodiment, is preferably arranged in a fuel tank 2 of a motor vehicle. In principle, different types of fuel, such as gasoline or diesel fuel, can be present in the fuel tank 2 in which the internal pipe 1 for a tank according to the invention is arranged. An internal pipe 1 for a tank has a fluid channel 3 and a pipe wall 4 surrounding the fluid channel 3 . Preferably, and in this exemplary embodiment, the tube wall 4 surrounding the fluid channel 3 has five layers. Preferably, and in this exemplary embodiment, the inner layer 5 is based on high density polyethylene (HDPE). Furthermore, the inner layer 5 can have additives, such as conductive additives, stabilizing additives, and the like. Conveniently, and in the exemplary embodiment, the inner layer 5 is followed by an adhesion promoter layer which improves the adhesion between the inner layer 5 and the layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com